Styrene-acrylic emulsion and preparation method thereof

A styrene-acrylic emulsion, styrene technology, applied in the direction of adding water repellent, coating, paper coating, etc., can solve the problems of unsatisfactory paper surface strength, poor water resistance, easy foaming, etc., and achieve good affinity and bonding force, maintaining paper strength, and the effect of small foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

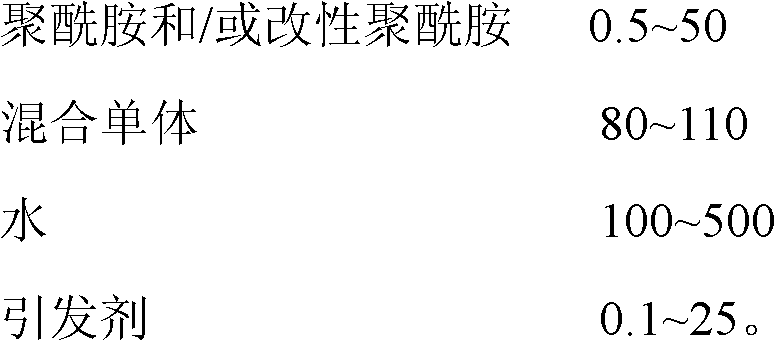

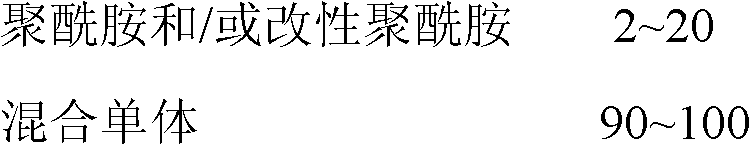

Method used

Image

Examples

Embodiment 1

[0038] Add 113g of adipic acid and 84.3g of diethylenetriamine into a 500mL reactor, stir, heat to reflux under normal pressure, vacuumize and dehydrate after 6h, the vacuum degree is -0.098Mpa, when the temperature rises to 180°C, stop vacuuming , continue to keep warm for 4h, then lower the temperature to 140°C, add 168g of water to obtain polyamide 1 with a solid content of 50%.

[0039] Weigh 31g of polyamide 1 and 235g of water in a 500mL reactor, adjust the pH value to 3.6, then heat to 75°C, then dropwise add 10g of 3wt% azobisisobutylamidine hydrochloride aqueous solution (wt refers to the mass fraction , hereinafter the same) and 100g of mixed monomer, dropwise for 4h. Wherein the mixed monomers include 55g styrene, 30g butyl acrylate and 15g butyl methacrylate. After the dropwise addition, continue to keep warm at about 75°C for 3 hours to obtain styrene-acrylic emulsion 1 with a solid content of 30%.

Embodiment 2

[0041] Add 20g of dodecanedioic acid, 100g of adipic acid, and 84.3g of diethylenetriamine into a 500mL reactor, stir, heat to reflux under normal pressure, vacuumize and dehydrate after 6h, vacuum degree -0.098Mpa, when the temperature rises to At 180°C, stop vacuuming, keep warm for 4 hours, then cool down to 140°C, add 176g of water to obtain polyamide 2 with a solid content of 50%.

[0042] Add 25.1 g of 2,3-epoxypropyltrimethylammonium chloride to polyamide 2, heat to 60° C., and keep warm for 4 hours to obtain modified polyamide 2 with a solid content of 53%.

[0043] Weigh 25g of modified polyamide 2 and 200g of water in a 500mL reactor, adjust the pH value to 5.7, heat to 80°C, then add 15g of 3wt% aqueous solution of azobisisobutylamidine hydrochloride, 90g of mixed mono Body and 10g mercaptoethanol aqueous solution (30wt%), dropwise time 4h. Wherein the mixed monomers include 60g styrene, 20g butyl acrylate and 10g tert-butyl acrylate. After the dropwise addition, ...

Embodiment 3

[0045] Add 17.6g of sebacic acid, 100g of adipic acid, and 84.3g of diethylenetriamine into a 500mL reactor, stir, and heat to reflux under normal pressure. After 6h, vacuumize and dehydrate. The vacuum degree is -0.098Mpa. ℃, stop vacuuming, continue to keep warm for 4 hours, then lower the temperature to 140 ℃, add 176g of water, and obtain polyamide 3 with a solid content of 50%.

[0046] Add concentrated hydrochloric acid dropwise to polyamide 3, control the temperature below 10°C, adjust the pH value to 4.2, then add 44.5g of hydrogen peroxide (50wt%), then program the temperature at a rate of 10°C / h, heat it to 60°C and keep it warm After 3 hours, the modified polyamide 3 was obtained with a solid content of 39%.

[0047] Weigh 35g modified polyamide 3, 200g water and 0.005g ferrous sulfate heptahydrate in a 500ml reactor, adjust the pH value to 4.2, heat to 80°C, then dropwise add 10g mixed initiator aqueous solution (containing 5wt% super Fluidic acid sodium and 3wt% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com