Process formula and preparation method of piston for pen type syringe

A pen-type syringe and piston technology, applied in the direction of hypodermic injection equipment, etc., can solve the problems of insufficient cleanliness of the production environment, unguaranteed product quality, high production costs, etc., to reduce the factors of human error and prevent chip shedding , The effect of good product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

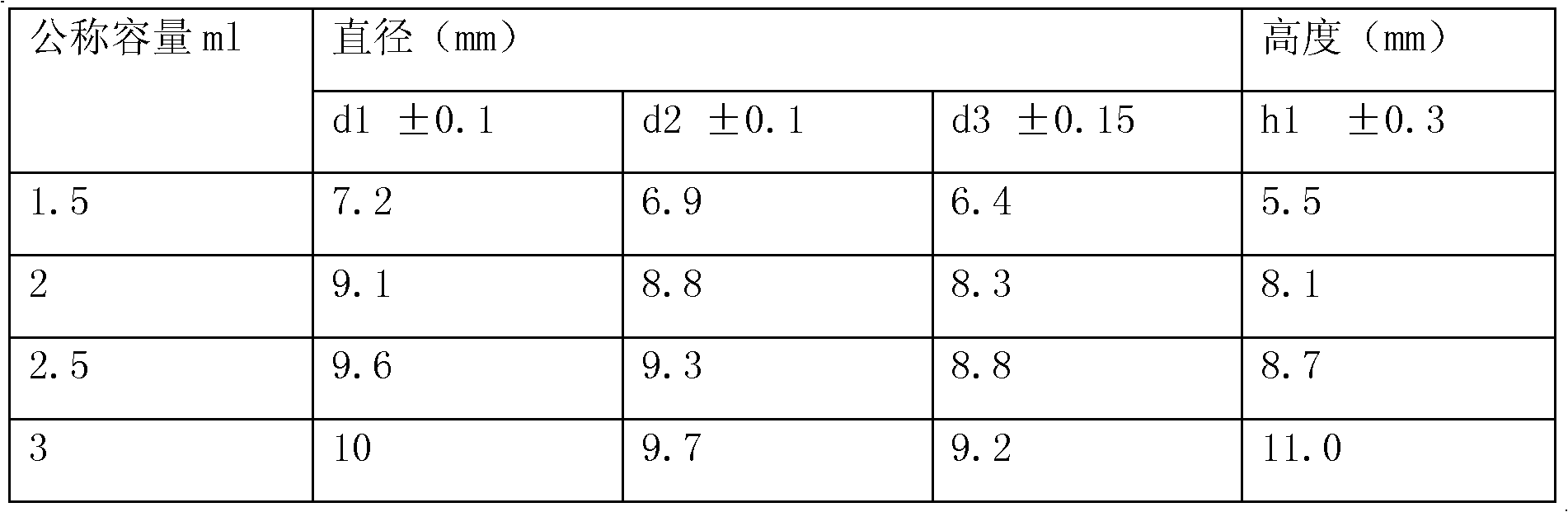

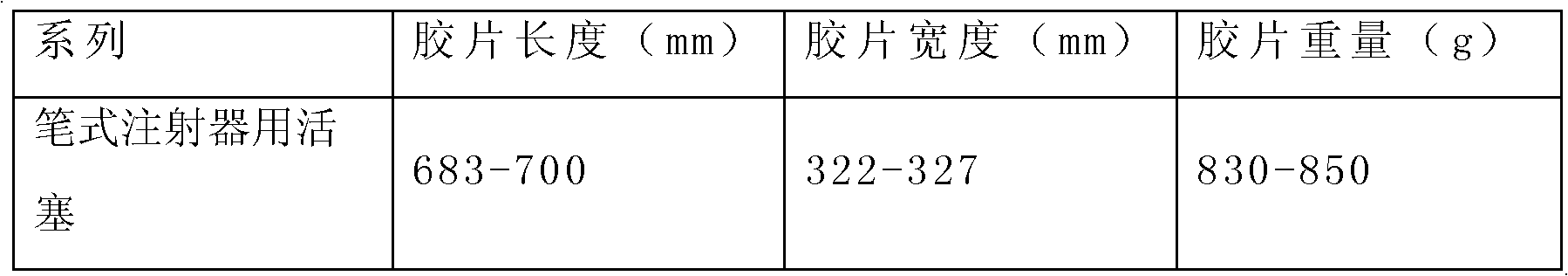

[0015] The raw material formula is: chlorinated butyl rubber 44500g, calcined kaolin 41500g, tert-octylphenol formaldehyde resin 655g, stearic acid 480g, zinc oxide 2260g, modified polyethylene 880g, titanium dioxide 1180g, semi-reinforced furnace carbon black 156g and magnesium oxide 60g.

[0016] The preparation method of a piston for a pen-type syringe comprises the following steps: (1) batching and banburying; (2) parking for 1-10 days; (3) preforming; (4) parking for 12 hours-10 days; Vulcanization thermoforming in a 300,000-class clean area environment; (6) edge removal in a 300,000-class clean area environment; (7) sieving in a 100,000-class clean area environment; (8) cleaning in a 10,000-class clean area environment , siliconization, drying, packaging.

[0017] Batching and banburying refers to mixing all kinds of raw materials evenly together, banburying in the banbury mixer for 8-10min, the glue discharge temperature is 95-105℃, and then adding it to the XKY-550 ru...

Embodiment 2

[0105] Change the vulcanization time to 260s, and the other preparation steps are the same as in Example 1.

Embodiment 3

[0107] Change the vulcanization time to 200s, and other preparation steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com