Water-resistant polyvinyl chloride (PVC) cable insulating material

A polyvinyl chloride cable and insulating material technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of not being able to meet water resistance, achieve high tensile strength, improve water resistance, and improve hydrophobicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

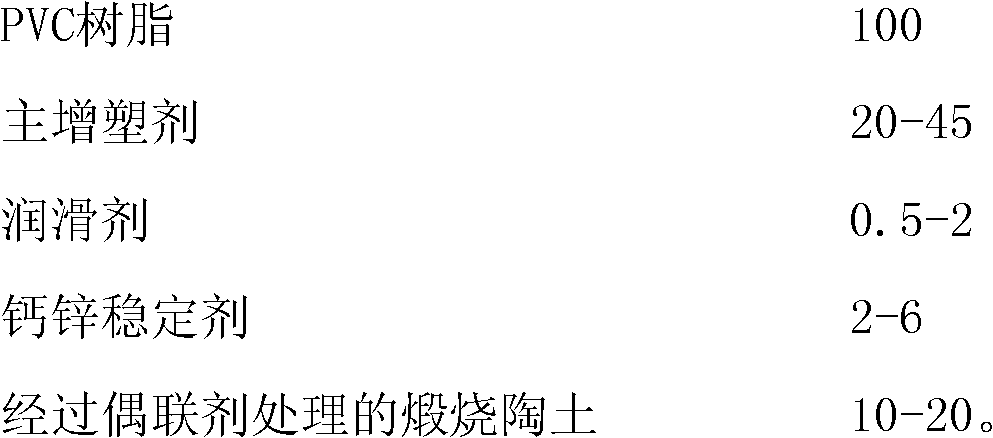

[0036] The raw materials are selected according to the following parts by weight:

[0037]

[0038] Among them, the PVC resin is a polyvinyl chloride resin with a degree of polymerization of 1300; the main plasticizer is DINP; the secondary plasticizer is DOP; the lubricant is paraffin and stearic acid (1:1); the calcium and zinc stabilizer is a solid 90℃ grade Calcium zinc stabilizer; calcined clay is kaolin that has been calcined at 700-750°C and dehydroxylated; pigment is titanium dioxide; filler is calcium carbonate; coupling agent is silane coupling agent KH171.

[0039] Firstly, the calcined clay is treated with a silane coupling agent, and then the materials are weighed according to the above formula and mixed in a high-speed mixer until the liquid is completely absorbed. The mixture is plasticized and granulated by a single screw outlet unit, and after drying, it is sealed Bagging.

[0040] The specific preparation method of the cable insulation material is:

[0041] (1) Put ...

Embodiment 2

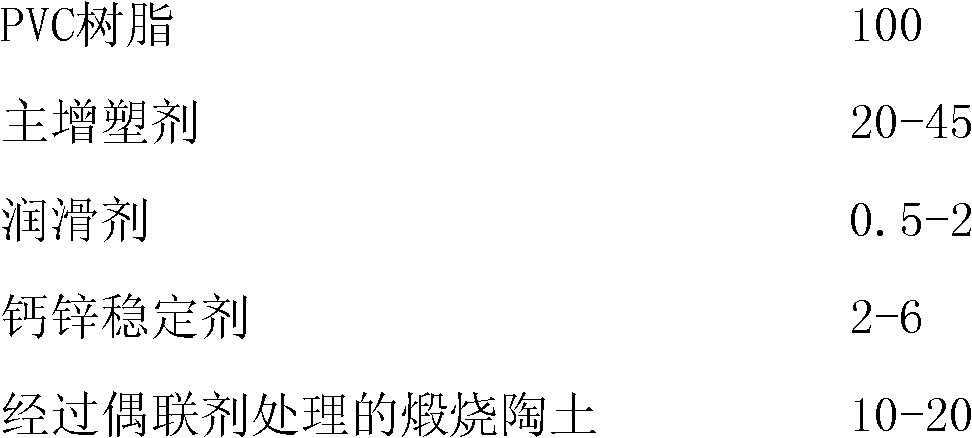

[0049] The raw materials are selected according to the following parts by weight:

[0050]

[0051] Among them, the PVC resin is a polyvinyl chloride resin with a degree of polymerization of 1500; the main plasticizer is epoxy soybean oil; the lubricant is paraffin; the calcium-zinc stabilizer is a liquid 90℃ calcium-zinc stabilizer; the calcined clay has a temperature of 700-750℃ Calcined dehydroxylated kaolin; pigment is lemon yellow; filler is talc; silane coupling agent is silane coupling agent A-172.

[0052] Firstly, the calcined clay is treated with a silane coupling agent, and then the materials are weighed according to the above formula and mixed in a high-speed mixer until the liquid is completely absorbed. The mixture is plasticized and granulated by a single screw outlet unit, and after drying, it is sealed Bagging.

[0053] The specific preparation method of the cable insulation material is:

[0054] (1) Put the calcined clay raw materials into a high-speed mixer, heat u...

Embodiment 3

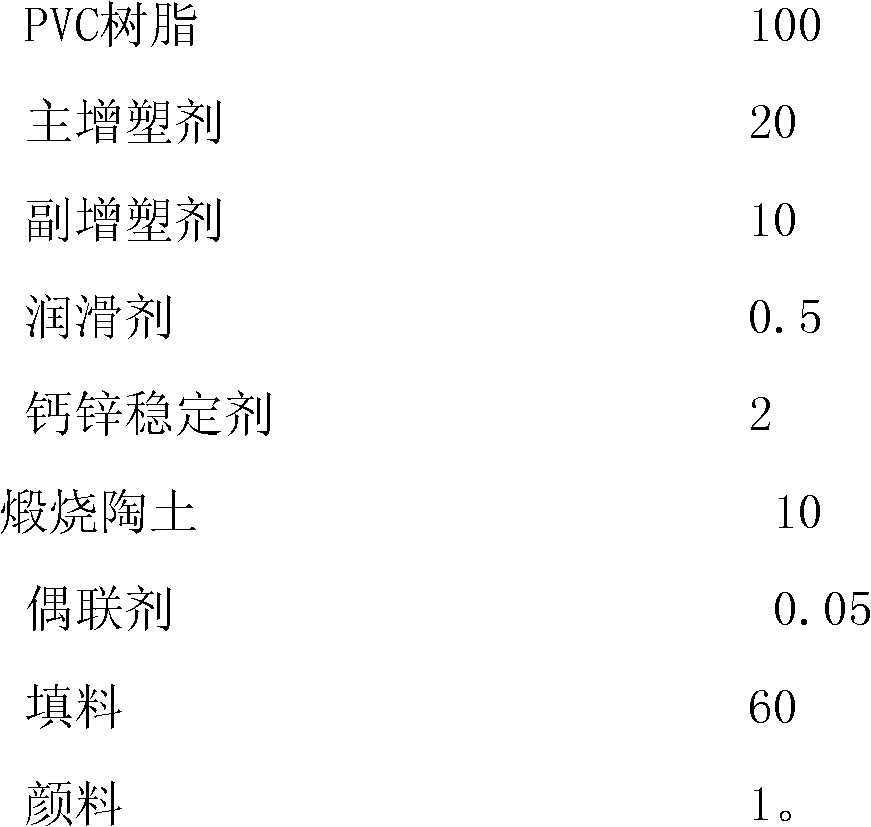

[0063] The raw materials are selected according to the following parts by weight:

[0064]

[0065] The PVC resin is a polyvinyl chloride resin with a degree of polymerization of 1300; the main plasticizer is TOTM; the lubricant is paraffin; the calcium-zinc stabilizer is a solid 90℃ calcium-zinc stabilizer; the calcined clay is dehydroxylated by calcination at 700-750℃ The kaolin; the pigment is: HR yellow; the silane coupling agent is the silane coupling agent KH151.

[0066] Firstly, the calcined clay is treated with a silane coupling agent, and then the materials are weighed according to the above formula and mixed in a high-speed mixer until the liquid is completely absorbed. The mixture is plasticized and granulated by a single screw outlet unit, and after drying, it is sealed Bagging.

[0067] The specific preparation method of the cable insulation material is:

[0068] (1) Put the calcined clay raw materials into a high-speed mixer, heat up to 105°C, add the coupling agent in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com