Methanol-gasoline-resisting static-electricity-conducting anticorrosive paint

An anti-corrosion coating and electrostatic conductive technology, which is applied in anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems that cannot meet the anti-corrosion requirements of methanol gasoline storage tanks, and avoid brittle paint films and resistance to strong solvent penetration corrosion , the effect of small internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

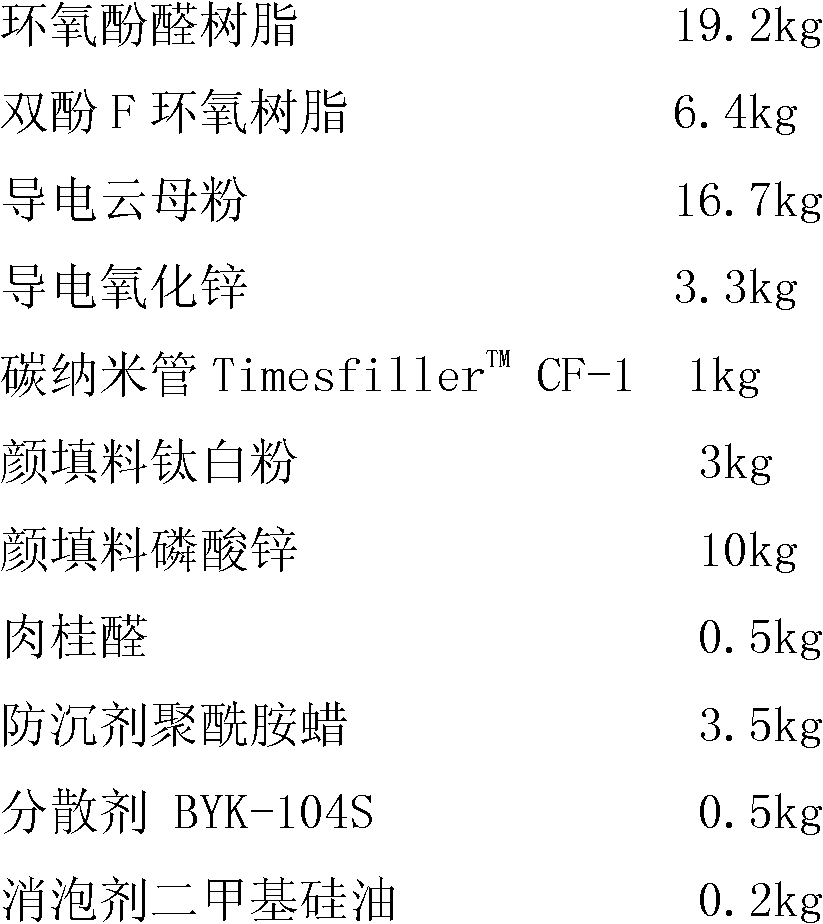

[0017] Weigh the following ingredients in proportion:

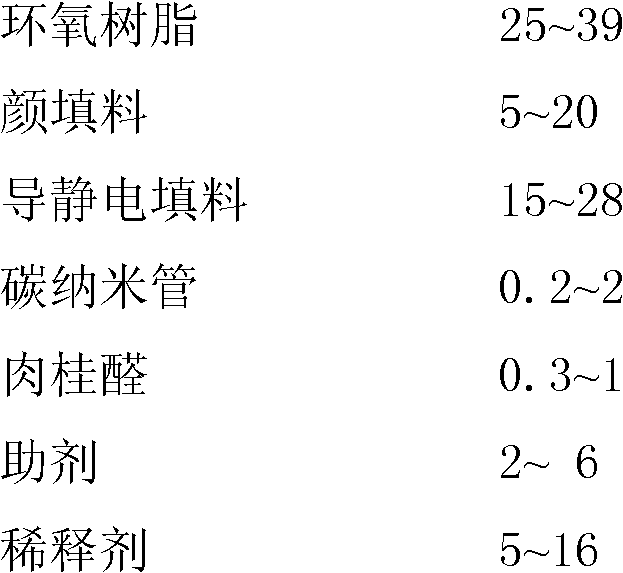

[0018] A component

[0019]

[0020]

[0021] B component

[0022] Curing agent D9050 5.5kg

[0023] Curing agent D9340 5.5kg

[0024] Take n-butanol, which is half of the formula amount, and add it to the mixture of bisphenol F epoxy resin and epoxy novolac resin, and stir evenly. After adding the formula amount of dispersant, defoamer and leveling agent, then add the formula amount of pigments and fillers titanium dioxide, zinc phosphate and mix well, then grind it on a sand mill to a fineness of 30 μm, and add anti-sedimentation agent after the fineness is qualified Polyamide wax, slowly add the formulated amount of static conductive filler. Finally, add the remaining n-butanol and stir evenly to obtain component A. Component B is obtained by uniformly mixing D9050 and D9340 according to the formula amount. When in use, slowly add component B to component A and stir evenly to obtain the final product.

Embodiment 2

[0026] Weigh the following ingredients in proportion:

[0027] A component

[0028]

[0029] B component

[0030] Curing agent D9050 11kg

[0031] The preparation method is the same as in Example 1.

Embodiment 3

[0033] Weigh the following ingredients in proportion:

[0034] A component

[0035]

[0036]

[0037] B component

[0038] Curing agent D9050 5.5kg

[0039] Curing agent D9340 3.5kg

[0040] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com