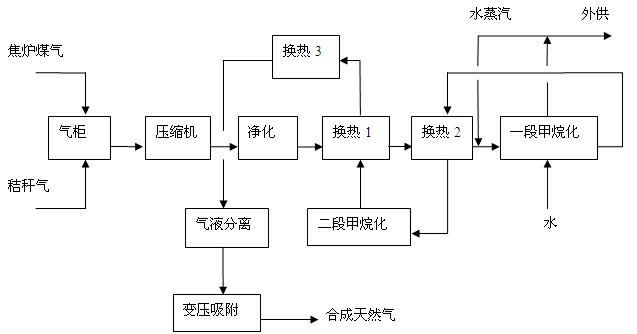

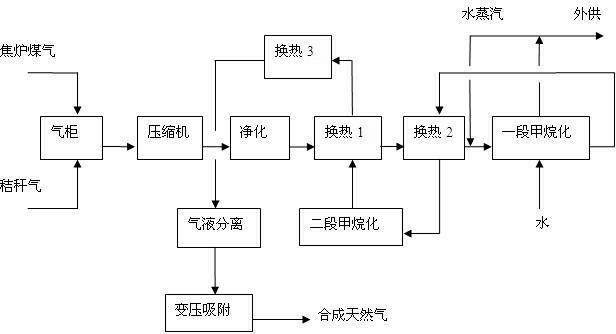

Method for preparing synthetic natural gas by coke oven gas in combination with straw gas

A technology for synthesizing natural gas and coke oven gas, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems that the economic benefits cannot be increased to the maximum, and achieve the effects of facilitating industrial application and promotion, reducing investment, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Adjust the raw material gas composition: coke oven gas composition (mol%) is: H 2 56.5, CH 4 25.6, CO 7.6, CO 2 2.3, N 2 5.4、C n h m 2.2, O 2 0.4, total sulfur 380mg / Nm 3 , trace amounts of benzene and naphthalene, tar 3 , gas volume 535.7kmol / h;

[0035] The composition of straw gas (mol%) is: H 2 48.2 CH 4 3.9, CO 23.6, CO 2 22.7, N 2 0.7, C n h m 0.6, O 2 0.3, total sulfur 180mg / Nm 3 , trace amounts of benzene and naphthalene, tar 3 ,gas volume 750kmol / h;

[0036] After mixing in the gas cabinet, the composition of the mixed gas (mol%) is: H 2 51.8, CH 4 12.9, CO 17.0, CO 2 14.1, N 2 2.6, C m h n 1.3, O 2 0.3, total sulfur 261mg / Nm 3 , trace amounts of benzene and naphthalene, tar 3 ;

[0037] (2) Compression purification: Pressurize the gas mixed in step (1) to 2.0Mpa through a compressor, pass through an adsorption bed equipped with activated carbon through temperature-swing adsorption, and then remove the raw material g...

Embodiment 2

[0046] (1) Adjust the raw material gas composition: coke oven gas composition (mol%) is: H 2 56.5, CH 4 25.6, CO 7.6, CO 2 2.3, N 2 5.4、C m h n 2.2, O 2 0.4, organic sulfur 380mg / Nm 3 , trace amounts of benzene and naphthalene, tar 3 , gas volume 446.5kmol / h;

[0047] The composition of straw gas (mol%) is: H 2 50.0, CH 4 3.6, CO 24.1, CO2 20.7, N 2 0.6, C m h n 0.7, O 2 0.3, organic sulfur 184mg / Nm 3 , trace amounts of benzene and naphthalene, tar 3 ,gas volume 750kmol / h;

[0048] After mixing in the gas cabinet, the composition of the mixed gas (mol%) is: H 2 52.6, CH 4 11.8, CO 17.7, CO 2 13.9, N 2 2.4, C m h n 1.3, O 2 0.3, total sulfur 263mg / Nm 3 , trace amounts of benzene and naphthalene, tar 3 ;

[0049] (2) Compression purification: pressurize the gas mixed in step (1) to 1.6Mpa through a compressor, and then remove benzene, naphthalene, tar and organic sulfur in the raw material gas after passing through the adsorption bed layer...

Embodiment 3

[0057] (1) Adjust the raw material gas composition: coke oven gas composition (mol%) is: H 2 54.2, CH 4 26.2, CO 6.3, CO 2 2.7, N 2 4.1, C m h n 3.0, O 2 0.4, total sulfur 376mg / Nm 3 , trace amounts of benzene and naphthalene, tar 3 , gas volume 446.5kmol / h;

[0058] The composition of straw gas (mol%) is: H 2 50.0, CH 4 3.6, CO 24.1, CO 2 20.7, N 2 0.6, C m h n 0.7, O 2 0.3, total sulfur 184mg / Nm 3 , trace amounts of benzene and naphthalene, tar 3 , gas volume 669.6kmol / h;

[0059] After mixing in the gas cabinet, the composition of the mixed gas (mol%) is: H 2 52.5, CH 4 12.8, CO 17.2, CO 2 13.6, N 2 2.0, C m h n 1.6, O 2 0.3, total sulfur 264mg / Nm 3 , trace amounts of benzene and naphthalene, tar 3 ;

[0060] (2) Compression purification: pressurize the gas mixed in step (1) to 0.5Mpa through a compressor, and then remove benzene, naphthalene, tar and organic sulfur in the raw material gas after passing through the adsorption bed lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com