Deformation zinc alloy, as well as manufacturing method and application thereof

A zinc alloy and intermetallic compound technology, applied in the field of deformed zinc alloy and its preparation, can solve problems such as lack of copper resources, and achieve the effects of increasing creep resistance, increasing strength, and reducing melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

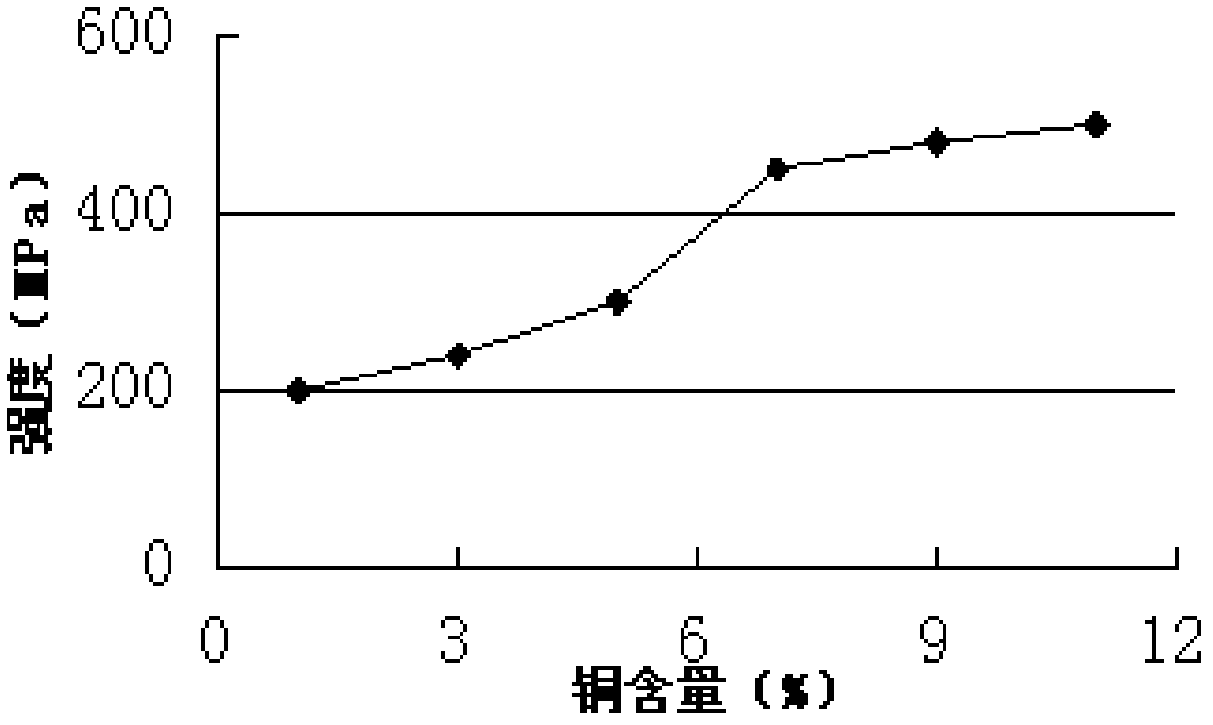

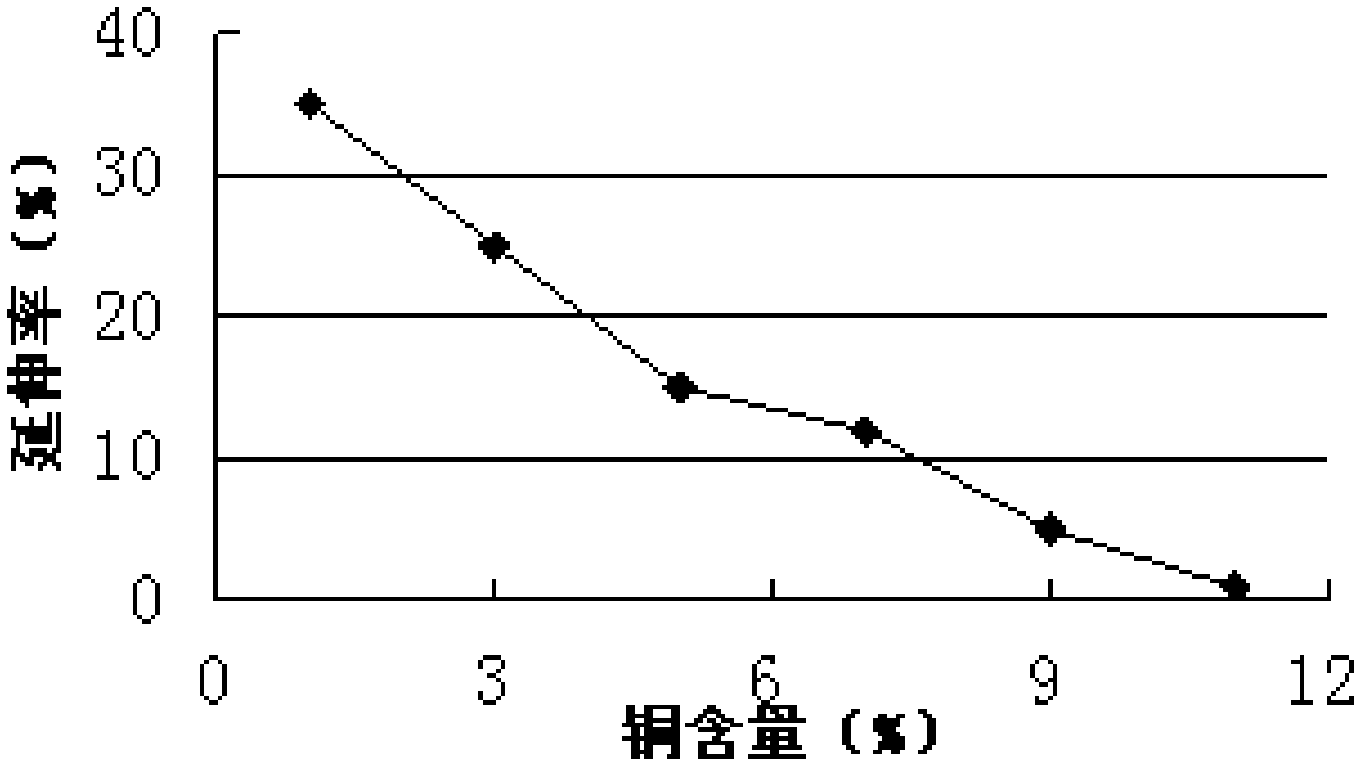

[0053] The melting composition is Mn: 0.5%, Cu: 2.0%, Co: 0.1%, and the balance of Zn, which is added in the form of pure zinc, zinc-copper master alloy, copper-manganese master alloy, and cobalt wire, using a reflection melting furnace with a capacity of 80 kg After being completely melted at 500°C, a die with a diameter of 170 mm is used to cast into a slab. After the cast slab has been flattened and wagoned, it is extruded into a S23.2mm hexagonal billet on a 1250-ton extrusion machine with an extrusion speed of 1.5mm / s, an extrusion temperature of 180°C, and an extrusion ratio of 42; Stretch into a finished bar of S22.0mm, and the pass processing rate of stretching is 5.0%.

[0054] After testing, it is known that the tensile strength of the finished rod is 400MPa, the elongation is 16%, and the Vickers hardness is Hv105.

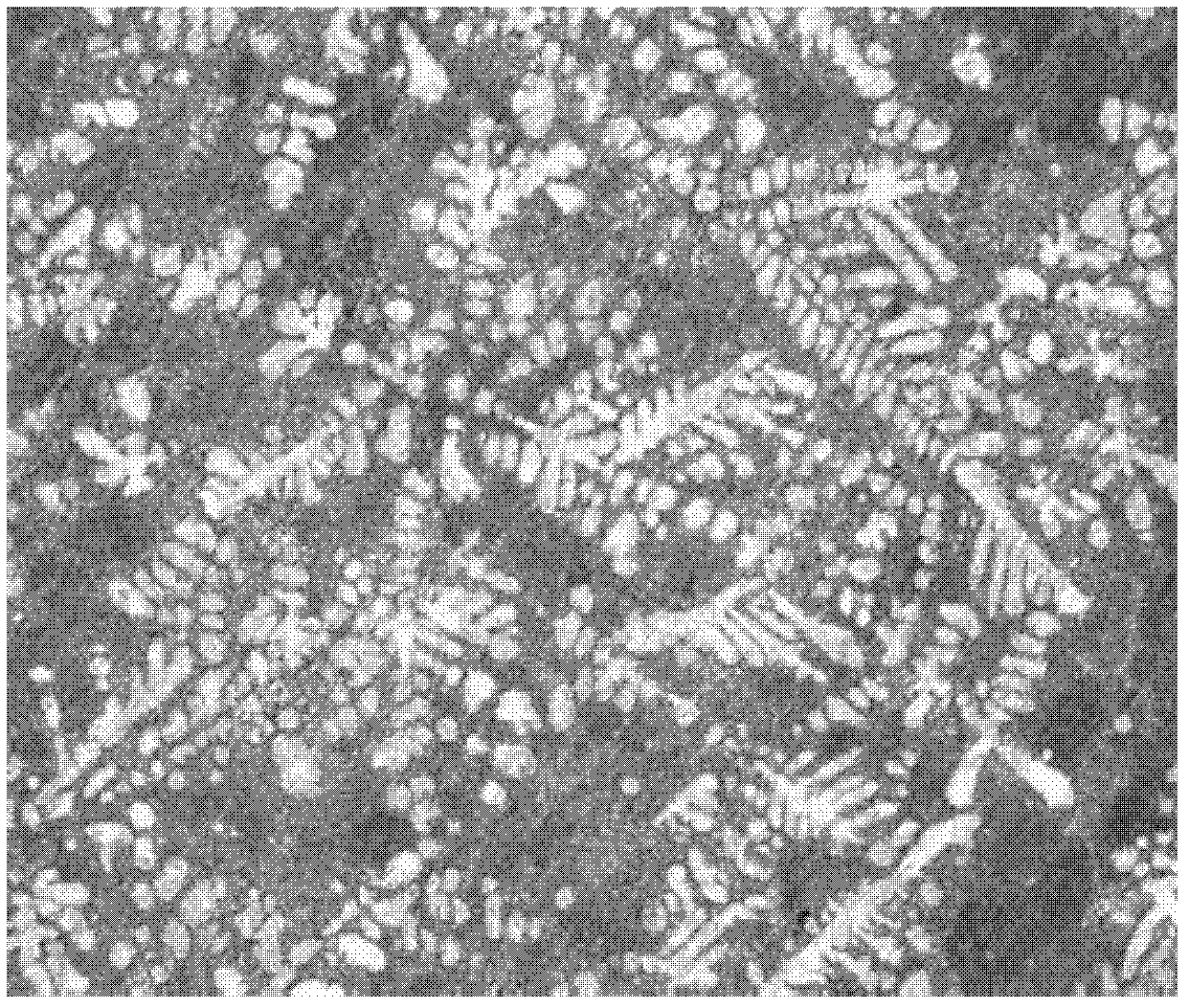

[0055] The metallographic structure of the finished product was observed by scanning electron microscope, and combined with the composition of the all...

Embodiment 2

[0064]The melting composition is Mn0.01%, Cu: 9.5%, Co: 0.02% and the balance of Zn, which are added in the form of pure zinc, zinc-copper, copper-manganese master alloy, and cobalt wire into a 50-kg medium-frequency melting furnace. After completely melting at 550°C, use a hard mold with a diameter of 90mm to make a billet. After peeling the billet, extrude it into a φ27.5mm round billet on an 800T extruder at a speed of 0.1mm / s, the extrusion temperature is 150°C, and the extrusion ratio is 10; and then stretched into a finished rod with a diameter of φ19.0mm, the processing rate of each stretch is 8.6%, and the total processing rate is 52%. After testing, the finished bar has a tensile strength of 490MPa, an elongation of 10%, and a Vickers hardness of Hv135.

[0065] The metallographic structure of the finished product was observed by scanning electron microscope, and combined with the composition of the alloy, it was determined that Zn 4 The volume content of Cu phase i...

Embodiment 3

[0068] The melting composition is Mn: 0.1%, Cu: 8.0%, Co: 0.05%, and the balance of Zn, which is added to the 80 kg capacity intermediate frequency melting furnace in the form of pure zinc, zinc-copper master alloy, copper-manganese master alloy and cobalt wire , after being completely melted at 600°C, it is cast into a slab with a hard mold with a diameter of 170 mm. After the billet has been flattened and wagoned, it is extruded into a round billet of φ15.0mm on a 1250-ton extrusion machine at an extrusion speed of 3.0mm / s, an extrusion temperature of 300°C, and an extrusion ratio of 128; Stretching to φ12.5mm, the pass processing rate of stretching is 8.2%, and the total processing rate is 30%. Get the finished coil line. After testing, the coil wire has a tensile strength of 475MPa, an elongation of 12%, and a Vickers hardness of Hv125.

[0069] The metallographic structure of the finished product was observed by scanning electron microscope, and combined with the compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com