Preparation method of paper with magnetic characteristics

A kind of magnetic properties and paper technology, applied in the field of paper manufacturing, can solve the problems of low resistance of ferrite materials, low paper whiteness, acid and alkali resistance, etc., and achieve the effect of not being easy to degauss, easy to operate, and not easy to be imitated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

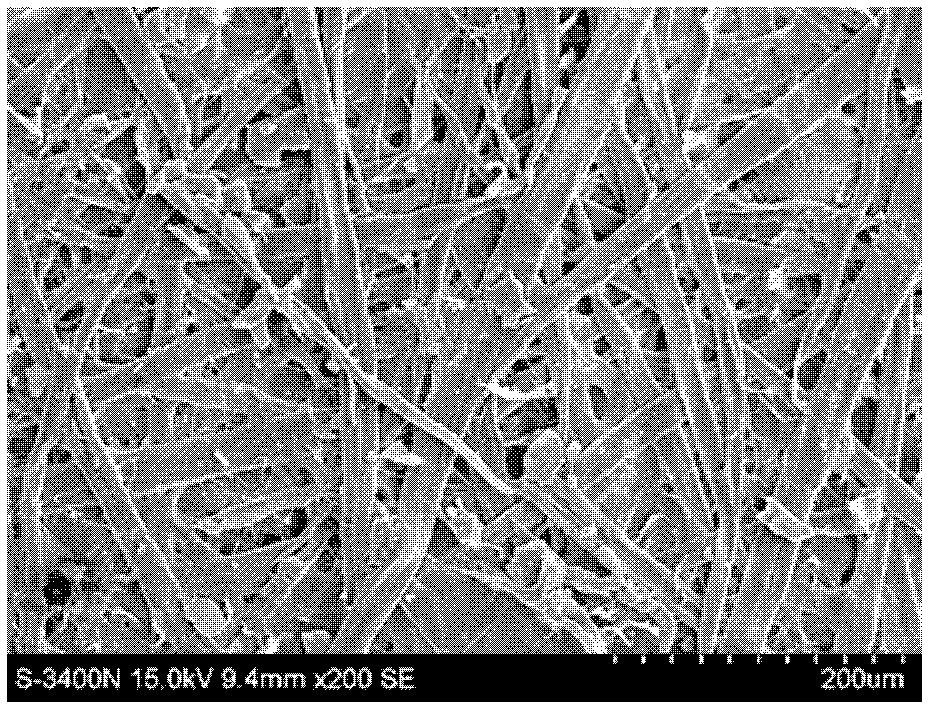

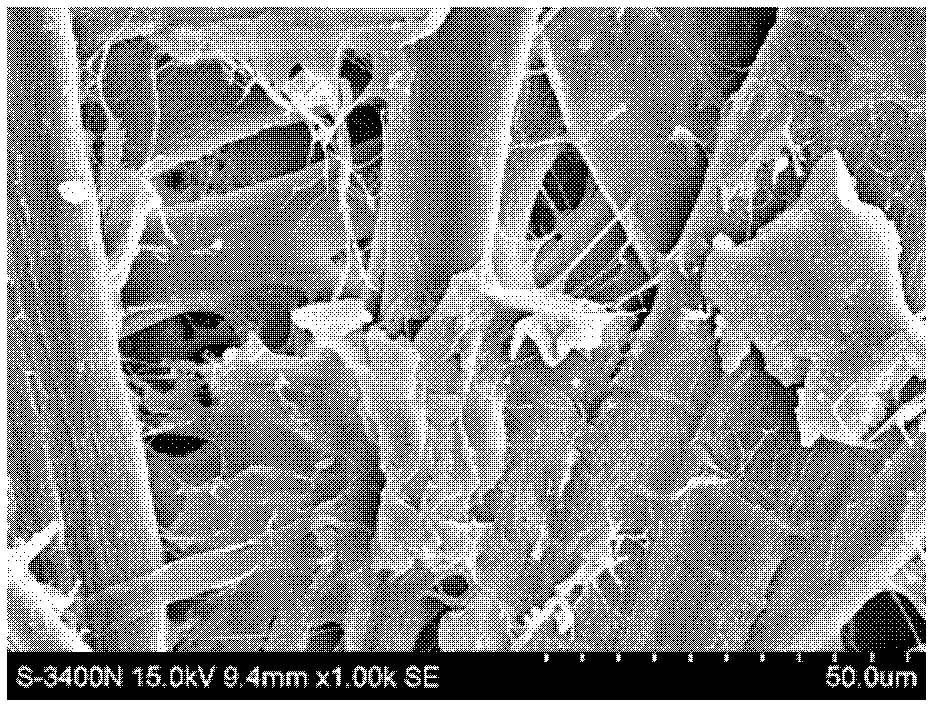

Image

Examples

Embodiment 1

[0019] Step 1: Preparation of Inorganic Materials with Magnetic Properties

[0020] 1) At first, according to mass fraction with 32% Tb 4 o 7 , 22% B 2 o 3 , 9% Al 2 o 3 , 25% SiO 2 , 8% P 2 o 5 , 2% BaO, 1% ZnO, and 1% NaCl are weighed and put into an agate mortar and mixed until the uniformity is greater than 98%, forming a batch;

[0021] 2) Next, at 1300°C, add the batch material into a corundum crucible wrapped with aluminum silicate fiber and covered, and melt at a heating rate of 20°C / min from 1300°C to 1460°C to form a glass melt. Insulate at the melting temperature for 3 hours, and stir for 1 minute with a corundum stirring rod every 1 hour during the melting process;

[0022] 3) Then, quickly pour the melted glass melt into distilled water at 20°C for water quenching, then remove the water-quenched sample, put it in an oven at 120°C for 4 hours, and then cool it naturally to room temperature;

[0023] 4) Finally, put the cooled particles into an alumina bal...

Embodiment 2

[0031] Step 1: Preparation of Inorganic Materials with Magnetic Properties

[0032] 1) At first, according to mass fraction with 30% Tb 4 o 7 , 16% B 2 o 3 , 18% Al 2 o 3 , 23% SiO 2 , 6% P 2 o 5 , 3% BaO, 1% ZnO, and 3% NaCl are weighed and put into an agate mortar and mixed until the uniformity is greater than 98%, forming a batch;

[0033] 2) Next, at 1300°C, the batch material is added into a corundum crucible wrapped with aluminum silicate fiber and covered, and melted at a heating rate of 20°C / min from 1300°C to 1550°C to form a glass melt. Insulate at the melting temperature for 2 hours, and stir for 1 minute with a corundum stirring rod every 1 hour during the melting process;

[0034] 3) Then, quickly pour the melted glass melt into distilled water at 10°C for water quenching, then remove the water-quenched sample, put it in an oven at 120°C for 6 hours, and then cool it naturally to room temperature;

[0035] 4) Finally, put the cooled particles into an alu...

Embodiment 3

[0043] Step 1: Preparation of Inorganic Materials with Magnetic Properties

[0044] 1) At first, according to mass fraction with 30% Tb 4 o 7 , 22% B 2 o 3 , 25% Al 2 o 3 , 15% SiO 2 , 2% P 2 o 5 , 3% BaO, 1% ZnO, and 2% NaCl are weighed and put into an agate mortar and mixed until the uniformity is greater than 98%, forming a batch;

[0045] 2) Next, at 1300°C, add the batch material into a corundum crucible wrapped with aluminum silicate fibers and covered, and melt at a heating rate of 20°C / min from 1300°C to 1500°C to form a glass melt. Insulate at the melting temperature for 4 hours, and use a corundum stirring rod to stir for 1 minute every hour during the melting process;

[0046] 3) Then, quickly pour the melted glass melt into distilled water at 30°C for water quenching, then remove the water-quenched sample, put it in an oven at 120°C for 6 hours, and then cool it naturally to room temperature;

[0047] 4) Finally, put the cooled particles into an alumina b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com