A method for rapid adsorption and catalytic oxidation of Congo red to treat organic wastewater

An organic wastewater, adsorption and catalysis technology, applied in the directions of oxidized water/sewage treatment, adsorbed water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high energy consumption, limited effect, high cost, and achieve simple phase composition, Time saving and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

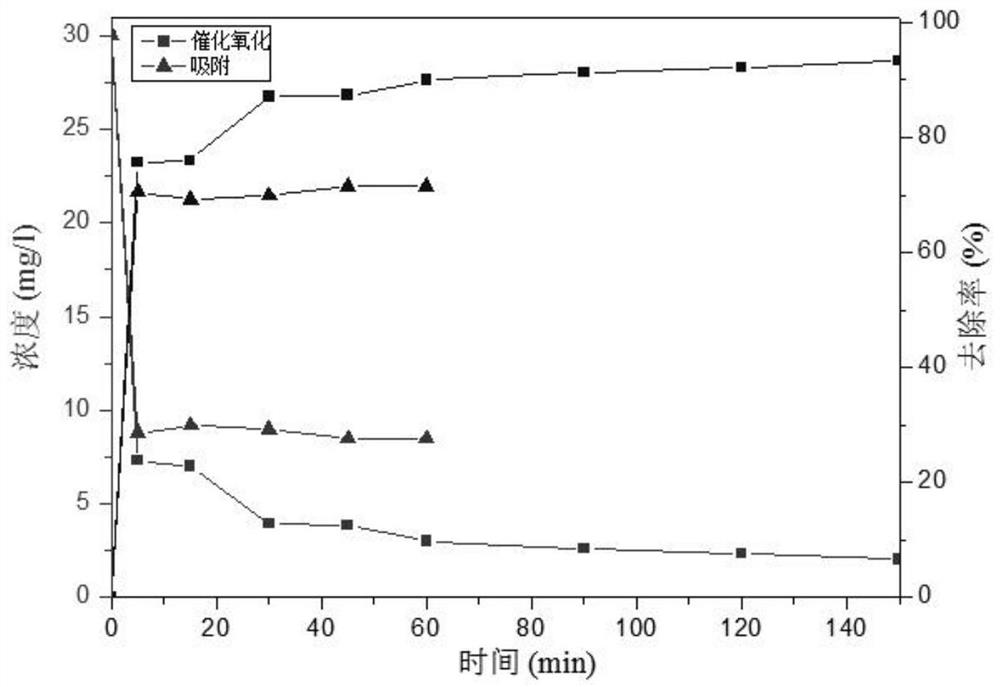

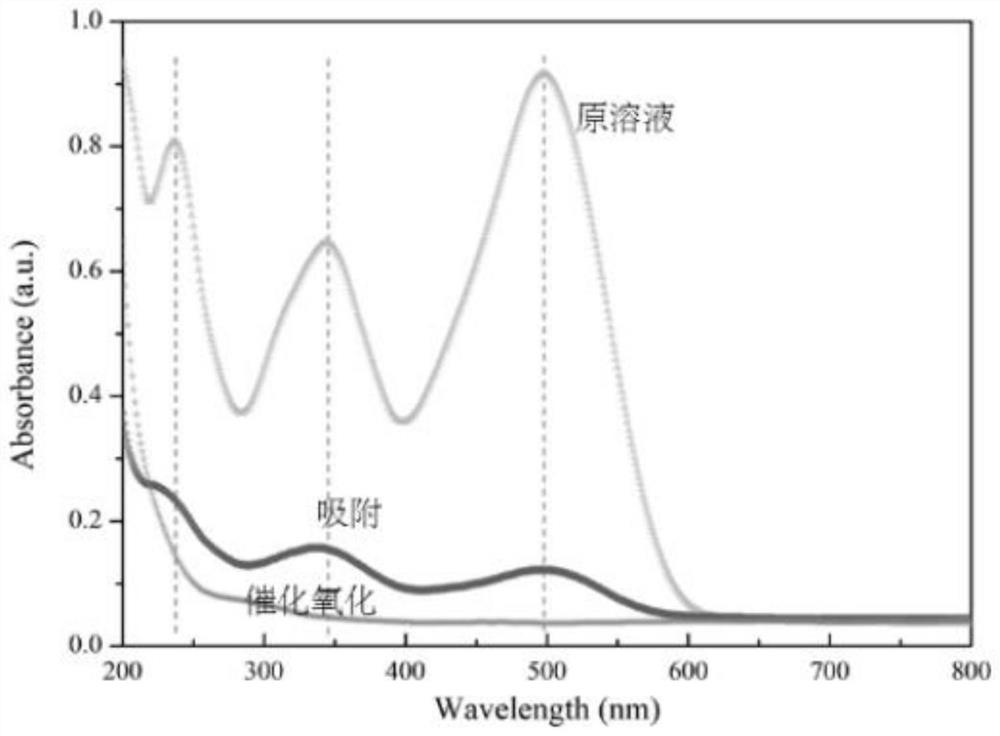

[0035] Specific embodiment one: a kind of rapid adsorption catalytic oxidation of Congo red of the present embodiment is carried out according to the following steps:

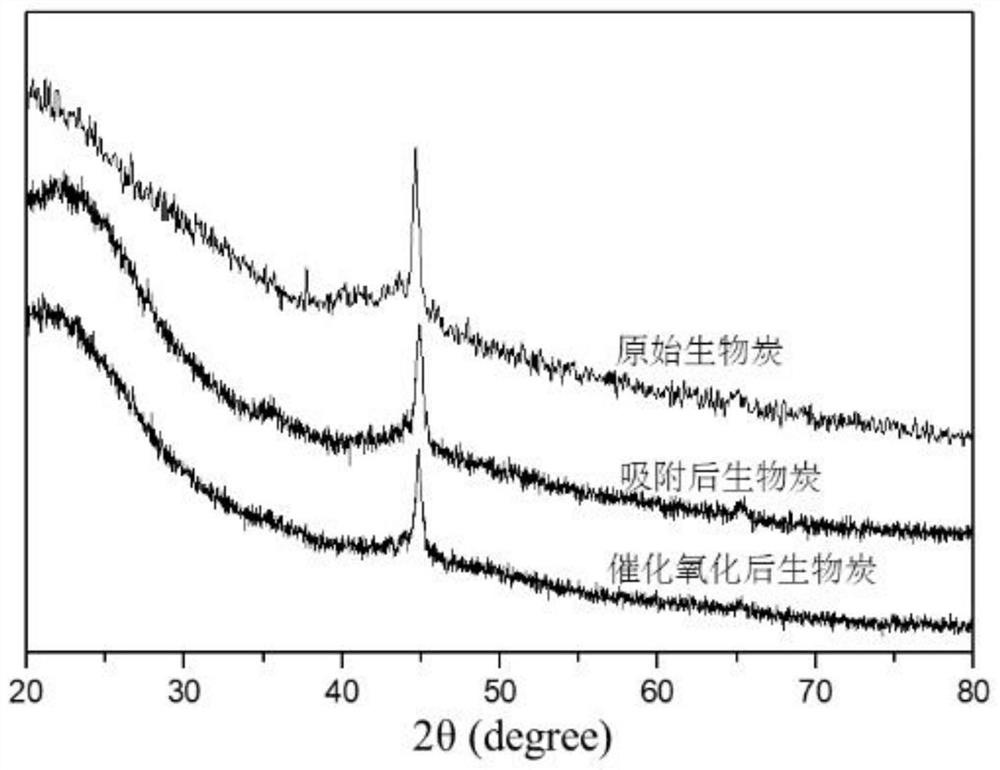

[0036] 1. Preparation of zero-valent iron biochar: crush rice straw and pass it through a 100-mesh sieve, then wash it twice with ultrapure water, then dry it in an oven at 60°C to constant weight, then take 5g of crushed rice straw and add it to 100mL In a mixed aqueous solution of polyethylene glycol 400 and ferric chloride hexahydrate, react in an oil bath at 100°C for 30 minutes under magnetic stirring. Raise the temperature to 700°C at a heating rate of / min, and carbonize at this temperature for 2 hours, and cool naturally to room temperature to obtain zero-valent iron biochar; the mixed aqueous solution of polyethylene glycol 400 and ferric chloride hexahydrate in the polyethylene The volume ratio of glycol 400 to water is 1:1, and the mass concentration of ferric chloride hexahydrate in the mixed aqueou...

specific Embodiment approach 2

[0038] Specific embodiment two: a kind of rapid adsorption catalytic oxidation of Congo red of the present embodiment is carried out according to the following steps:

[0039] 1. Preparation of zero-valent iron biochar: crush rice straw and pass it through a 100-mesh sieve, then wash it twice with ultrapure water, then dry it in an oven at 60°C to constant weight, then take 5g of crushed rice straw and add it to 100mL In a mixed aqueous solution of polyethylene glycol 400 and ferric chloride hexahydrate, react in an oil bath at 100°C for 30 minutes under magnetic stirring. Raise the temperature to 700°C at a heating rate of / min, and carbonize at this temperature for 2 hours, and cool naturally to room temperature to obtain zero-valent iron biochar; the mixed aqueous solution of polyethylene glycol 400 and ferric chloride hexahydrate in the polyethylene The volume ratio of glycol 400 to water is 1:1, and the mass concentration of ferric chloride hexahydrate in the mixed aqueou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com