Multi-element thermal fluid auxiliary gravitational displacement process

A multi-component thermal fluid and auxiliary gravity technology, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., which can solve the problem of high processing costs of high-temperature produced fluids, increased temperature, and difficulty in guaranteeing the dryness of bottom-hole steam. problems, to achieve the effect of improving thermal efficiency and economic benefits, increasing displacement and oil drainage, and enriching the mechanism of crude oil viscosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

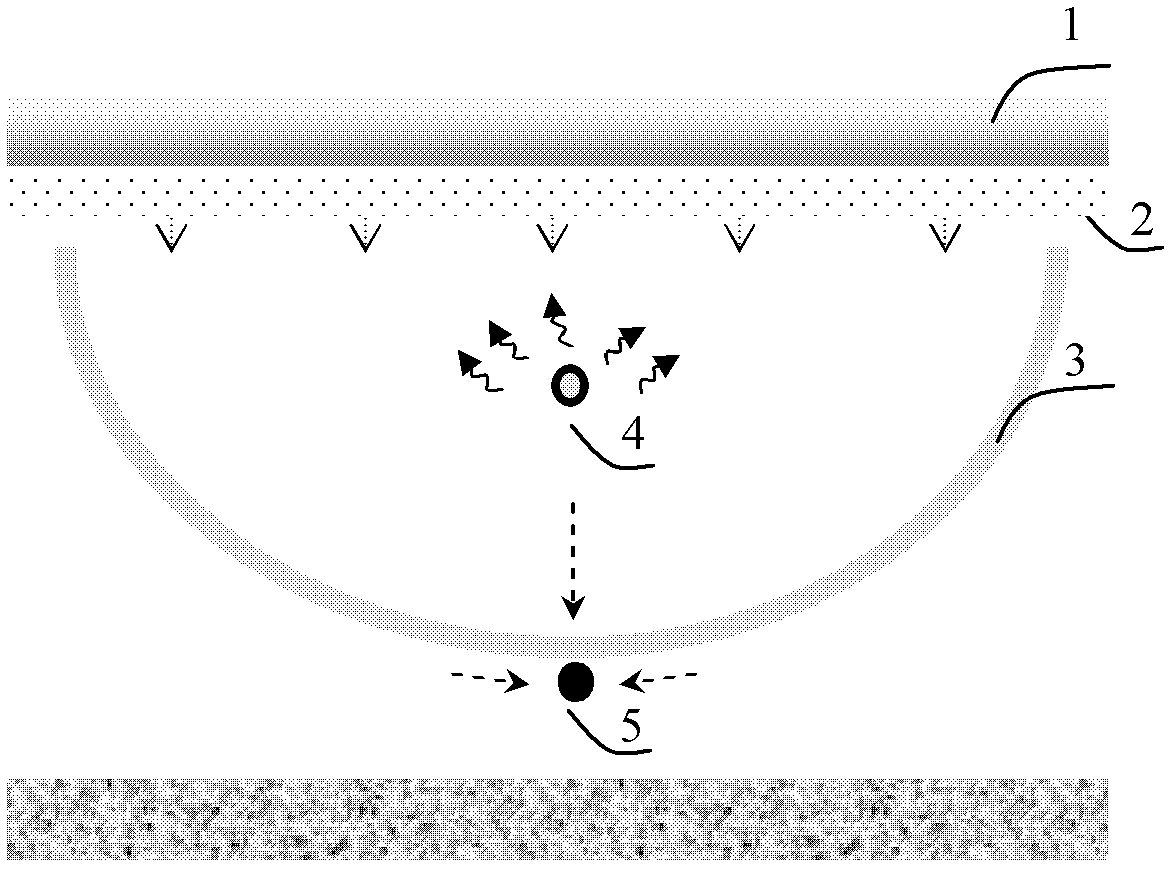

[0030]The general principle of the present invention is explained below by taking a certain offshore heavy oil well in Bohai Bay as an example, but it should be noted that the present invention is by no means limited to offshore heavy oil wells.

[0031] The reservoir depth is 1000m, the crude oil viscosity at the reservoir temperature is 13000mPa·s, the original formation pressure is about 10.0MPa, the oil layer thickness is 35-45m, and there is 5-10m bottom water, and the horizontal permeability is 2-3μm 2 , the ratio of vertical permeability to horizontal permeability is 0.3-0.5, the porosity is 33%, and the oil saturation is 71%.

[0032] 1. Well layout parameters

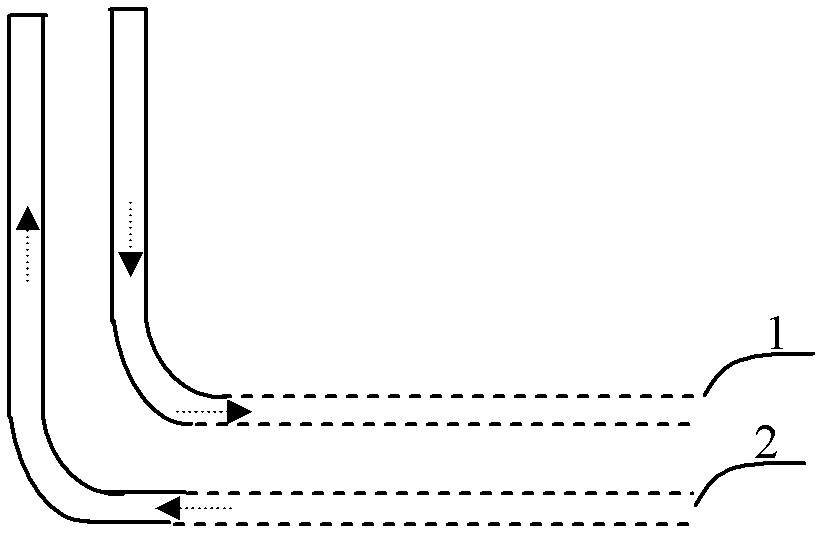

[0033] Produced by combining double horizontal wells, such as image 3 As shown, the vertical distance between the horizontal injection well 1 and the overlying strata is 4m. In order to prevent bottom water coning, the horizontal production well 2 is deployed at a place 7m above the oil-water contact, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com