Integrated optical chip based on glass-based ion exchange buried optical waveguide and manufacturing method

An ion exchange, integrated optics technology, applied in the directions of light guide, optics, optical components, etc., can solve the problems of high process requirements, large polarization dependence, affecting the stability and reliability of the chip, and achieve short process steps, low cost, low stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

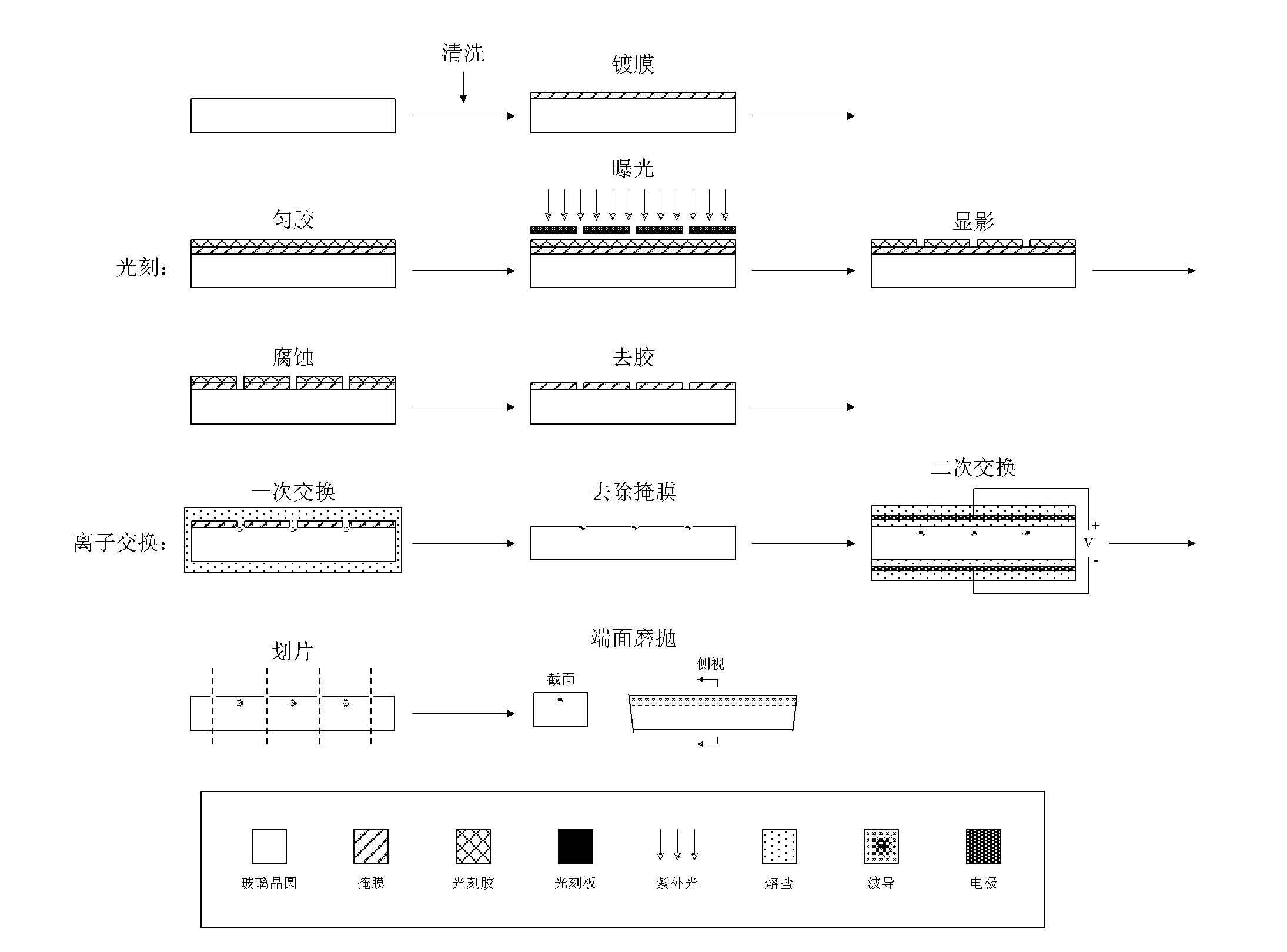

Method used

Image

Examples

Embodiment 1

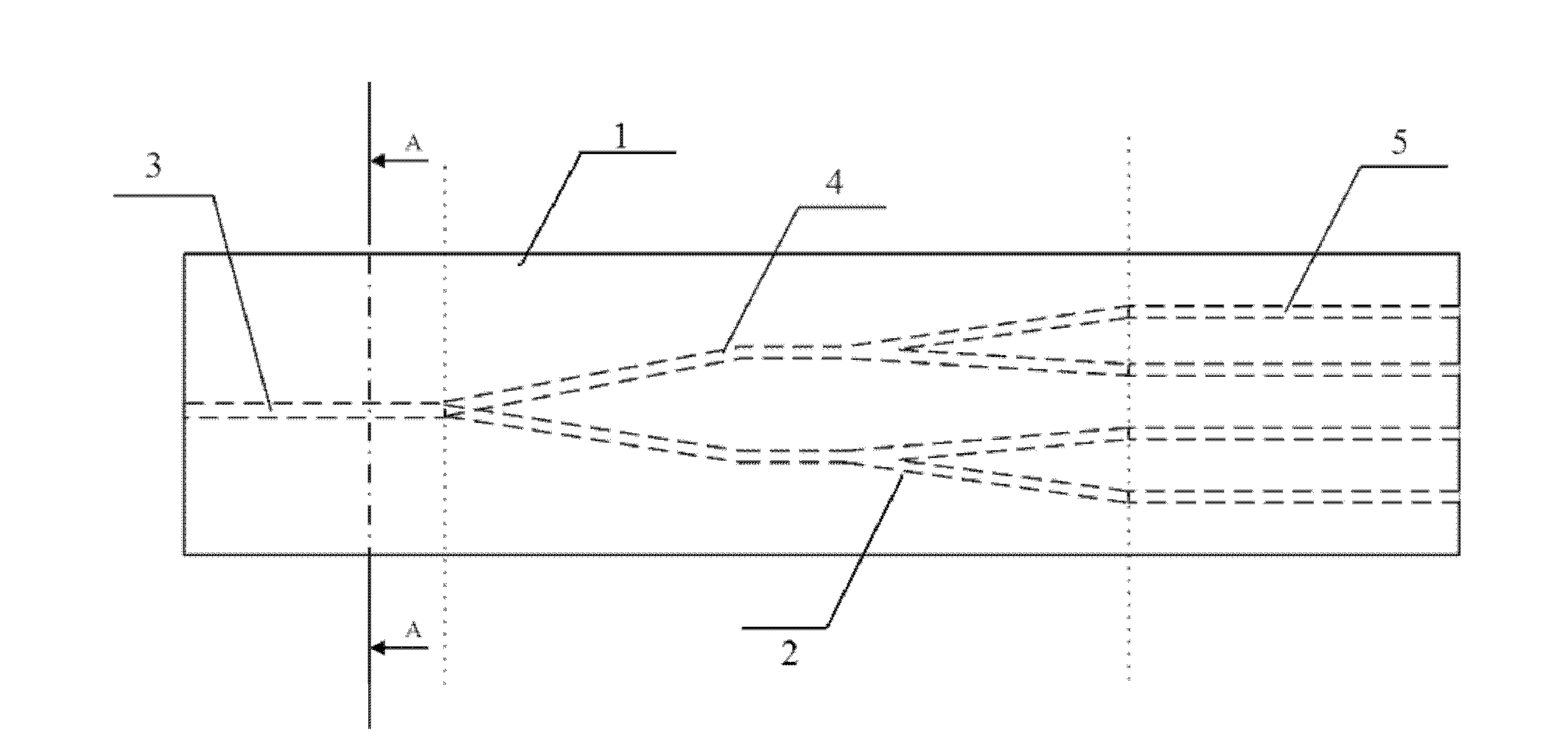

[0043] Such as Figure 1-4 As shown, a 1×4 optical splitter chip based on a glass-based ion-exchange buried optical waveguide is used for illustration.

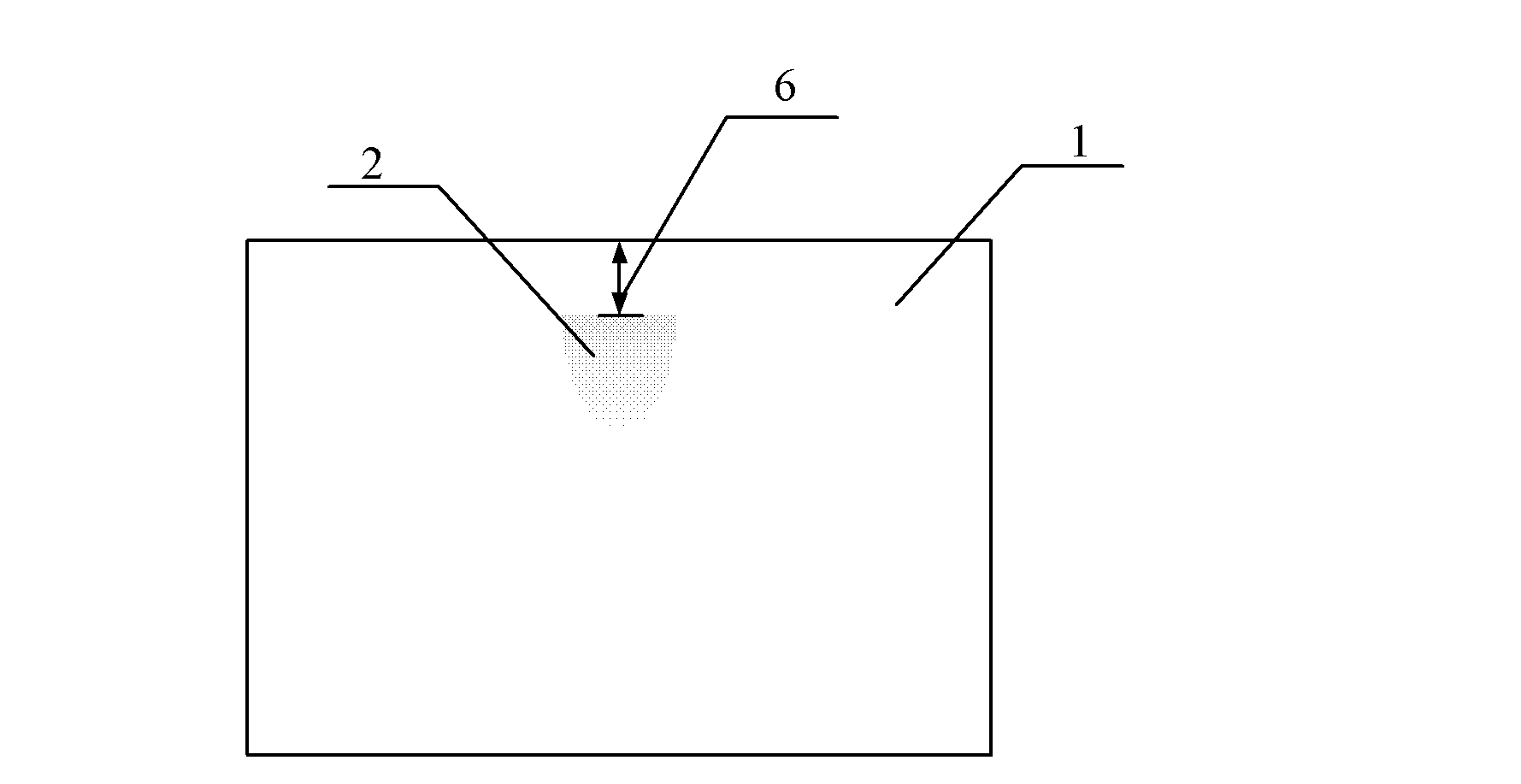

[0044] The chip is mainly composed of a glass substrate 1 and an ion exchange buried optical waveguide 2; the ion exchange buried optical waveguide 2 is located inside the glass substrate 1, and the distance 6 from the upper surface of the glass substrate is 15 μm. The ion exchange buried optical waveguide is divided into three parts in the horizontal direction in the glass substrate: the input waveguide area 3, the functional structure area 4 and the output waveguide area 5, and the functional structure area 4 is connected to the input waveguide area 3 and the output waveguide area 5 , in this embodiment, the input waveguide area 3 is an input single-port straight waveguide area, the functional structure area 4 is a cascaded branch structure area, and the output waveguide area 5 is an output four-port straight waveguide arra...

Embodiment 2

[0047] see Figure 1-4 As shown, a 2×2 optical coupler chip based on a glass-based ion-exchange buried optical waveguide is mainly composed of a glass substrate and an ion-exchange buried optical waveguide; the ion-exchange buried optical waveguide is located inside the glass substrate. The distance 6 from the upper surface of the glass substrate is 7000 μm. The ion exchange buried optical waveguide is divided into three parts in the glass substrate: the input two-port straight waveguide array area, the 2×2 coupling area and the output two-port straight waveguide array area. The integral ion-exchange buried optical waveguide realizes the function of 2×2 optical coupler. The ion-exchange buried optical waveguide is a graded-refractive-index waveguide. The vertical cross-sectional profile is in the shape of a "comet". The refractive index near the "comet nucleus" is the largest, and the refractive index of the outward part gradually decreases, showing a "comet tail" distributio...

Embodiment 3

[0050] An integrated optical chip based on a glass-based ion exchange buried optical waveguide, the integrated optical chip is mainly composed of a glass substrate and an ion exchange buried optical waveguide; the upper side of the waveguide of the ion exchange buried optical waveguide is not completely separated from the upper surface of the glass substrate , the distance between the ion-exchange buried optical waveguide and the upper surface of the glass substrate is 0 μm.

[0051] The ion-exchange buried optical waveguide is a graded-index waveguide, which is divided into three regions in the horizontal direction in the glass substrate: the input waveguide region, the functional structure region and the output waveguide region, and the functional structure region is connected to the input waveguide area and the output waveguide area. Wherein: the input waveguide area is composed of a single straight waveguide; the structure of the functional structural area is a shunt struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com