Geopolymer cement and use thereof

A geopolymer cement, cement technology, applied in the field of structure and construction, can solve the problems of increasing the amount of water, reducing plasticity, and short cement hardening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

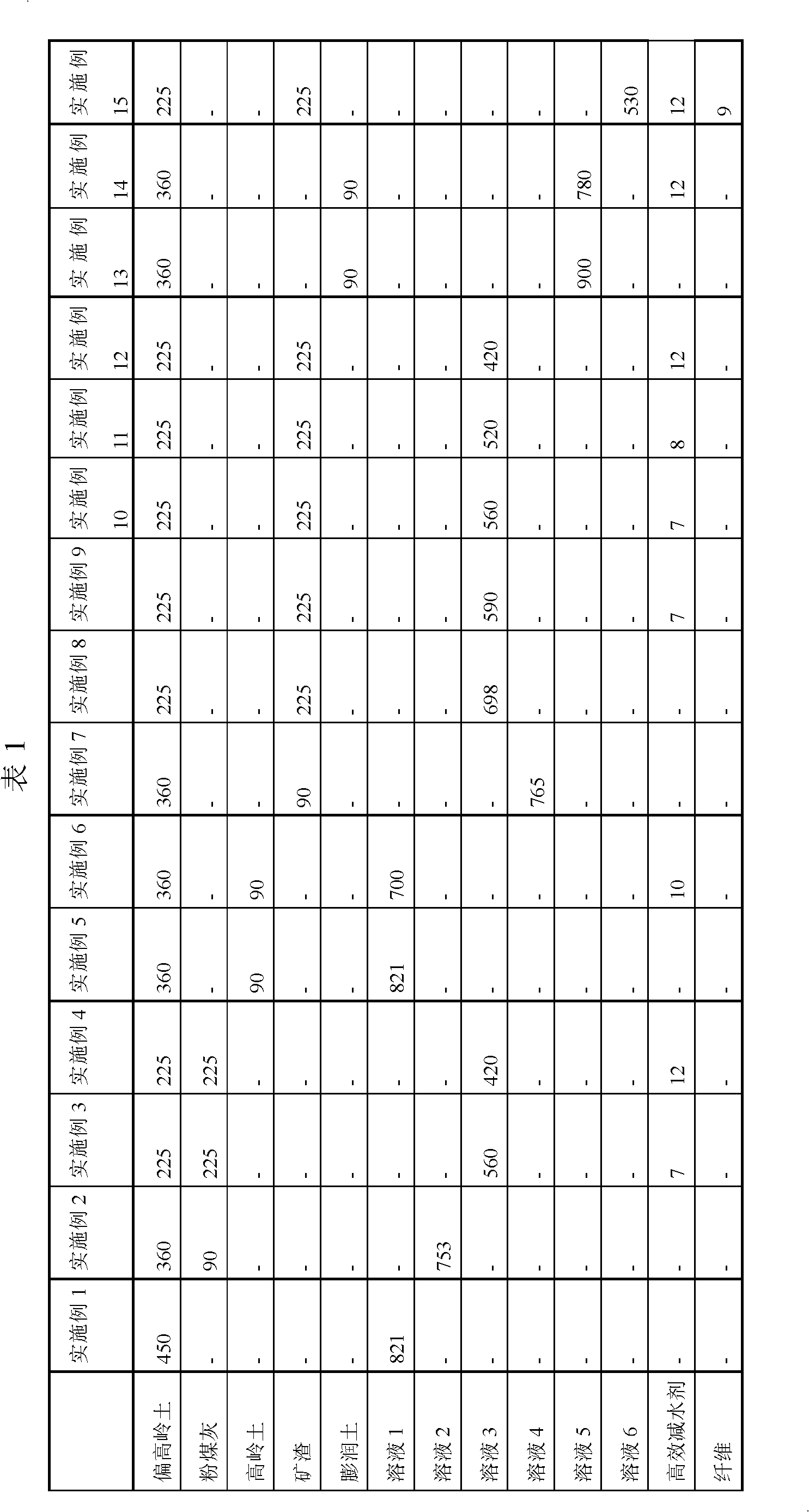

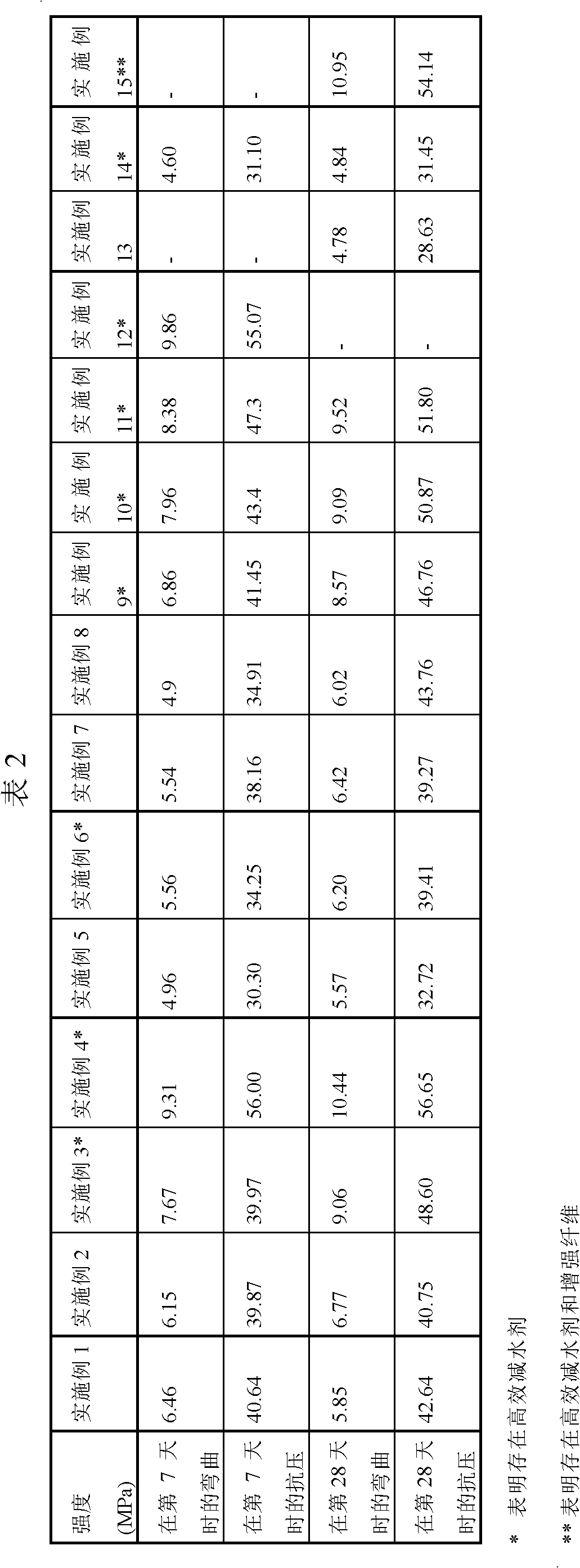

[0065] The present invention may be better understood from the following examples, which are provided for illustration only.

[0066] In these examples, the following components were used:

[0067] - Metakaolin: sold by AGS Minéraux under the name Argical-M 1200S (powder);

[0068] - Fly Ash: Sold by Surchiste under the name Siliconoline products (powder);

[0069] - Kaolin: sold by AGS Minéraux under the name Argirec B24 (powder);

[0070] - Blast Furnace Slag: a product (powder) sold by Slag under the name Crushed Slag 0 / 4;

[0071] -Bentonite: The Société the product sold under the name Impersol (powder) by des Bentonites et Dérivés;

[0072] - Aramid fiber: sold by Teijin under the name Technora Synthetic organic fibers of T321;

[0073] - Aqueous solution of sodium silicate: the following solution is sold from VWR under the name sodium silicate solution TECHNICAL (SiO 2 :Na 2 O weight ratio = 3.25) and solid sodium hydroxide (97%) Preparation:

[0074] o Solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com