Process for production of polyamideimide resin microparticles, and polyamideimide resin microparticles

A polyamide-imide resin and particle technology, which is applied in the preparation of polyamide-imide resin particles and the field of polyamide-imide resin particles, can solve the problems of lack of reproducibility and large particle size variation, and achieves The effect of increasing the degree of freedom, simple and stable preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] As the preparation method of PAI resin, the following methods are known: the isocyanate method using trimellitic anhydride and diisocyanate as raw materials (for example, Japanese Patent Publication No. 50-33120 communique); making chlorinated trimellitic anhydride and diamine in N,N-dimethyl Acyl chloride method polymerized in acetamide (for example, Japanese Patent Publication No. 42-15637); in the presence of 3-valent or 5-valent inorganic or even organic phosphorus compounds, aromatic tricarboxylic acid, its anhydride or its ester and di A direct polymerization method in which amines react in a solution (for example, Japanese Patent Publication No. 49-4077); the PAI resin in the present invention can be prepared by any method.

[0040] As said polyamide-imide resin, a commercial item can also be selected suitably and used, Specifically, the polyamide-imide resin TI-5013P by Toray Co., Ltd., Toron by Solbey, etc. can be used.

[0041] [Preparation of PAI resin microp...

Embodiment 1

[0116] [Dissolution process] (b1)

[0117] A 1000ml autoclave of a dissolution tank was equipped with a stirrer, a temperature measuring device, and an extraction pipe for an internal solution. A connecting pipe that can be opened and closed by a valve is installed on the extraction pipe. In addition, as a receiving tank for flash crystallization, install a stirrer, a condenser, and a gas vent pipe on a 1000ml autoclave, and install the other end of the connection pipe (flash crystallization outlet) from the above-mentioned dissolution tank on the immersion receiving tank. position in the bath.

[0118] 12 g of PAI resin (manufactured by Toray Co., Ltd., TI-5013P, the powder used in the following examples) and 338 g of NMP (manufactured by Kanto Chemical Co., Ltd.) (PAI resin concentration: 3% by mass) were placed in a dissolution tank, and nitrogen replacement was performed. It was sealed and the internal temperature was raised to 240° C. while stirring, and then stirred fo...

Embodiment 2

[0123] Example 2 (dissolution process: b1, precipitation process: b2)

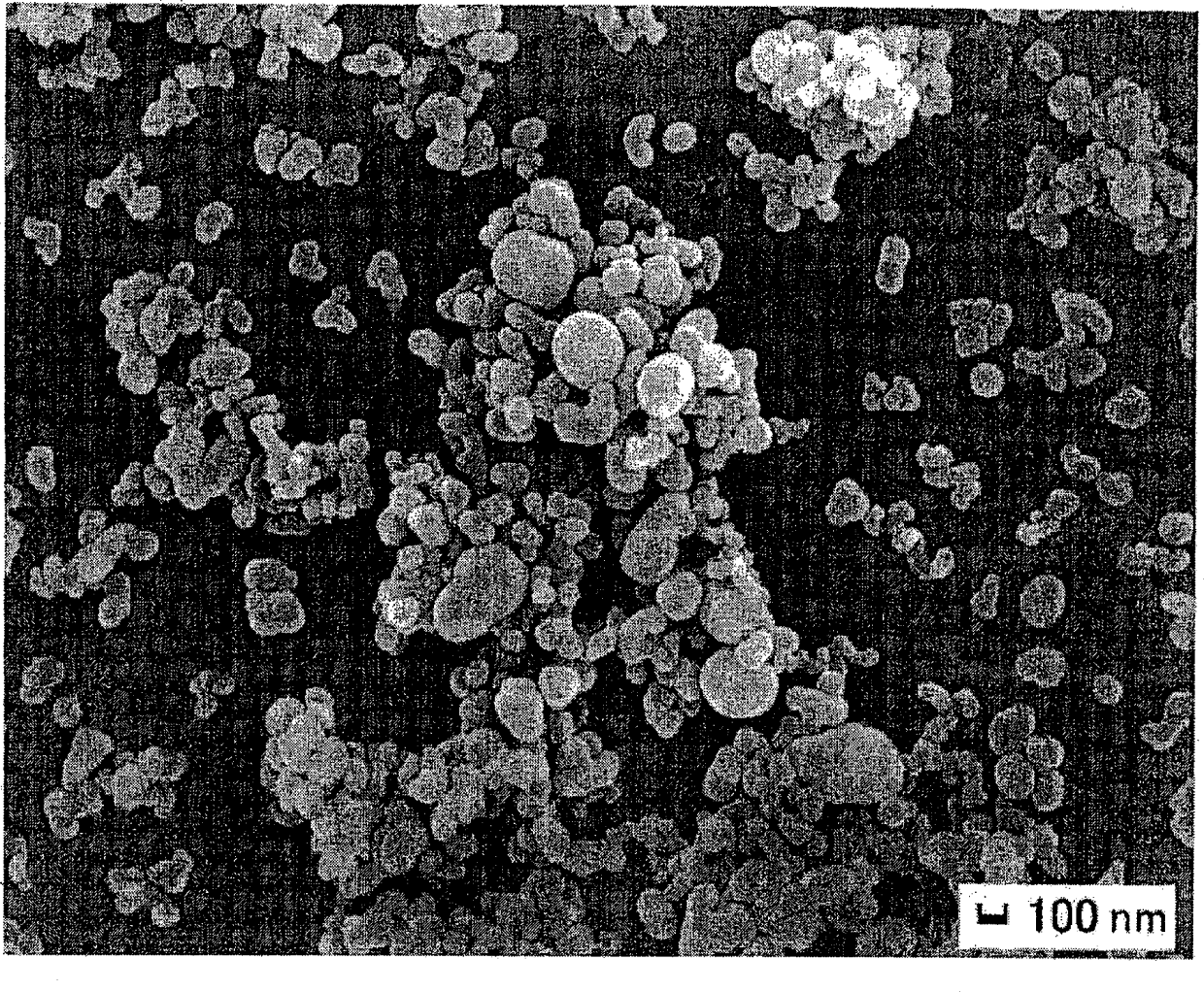

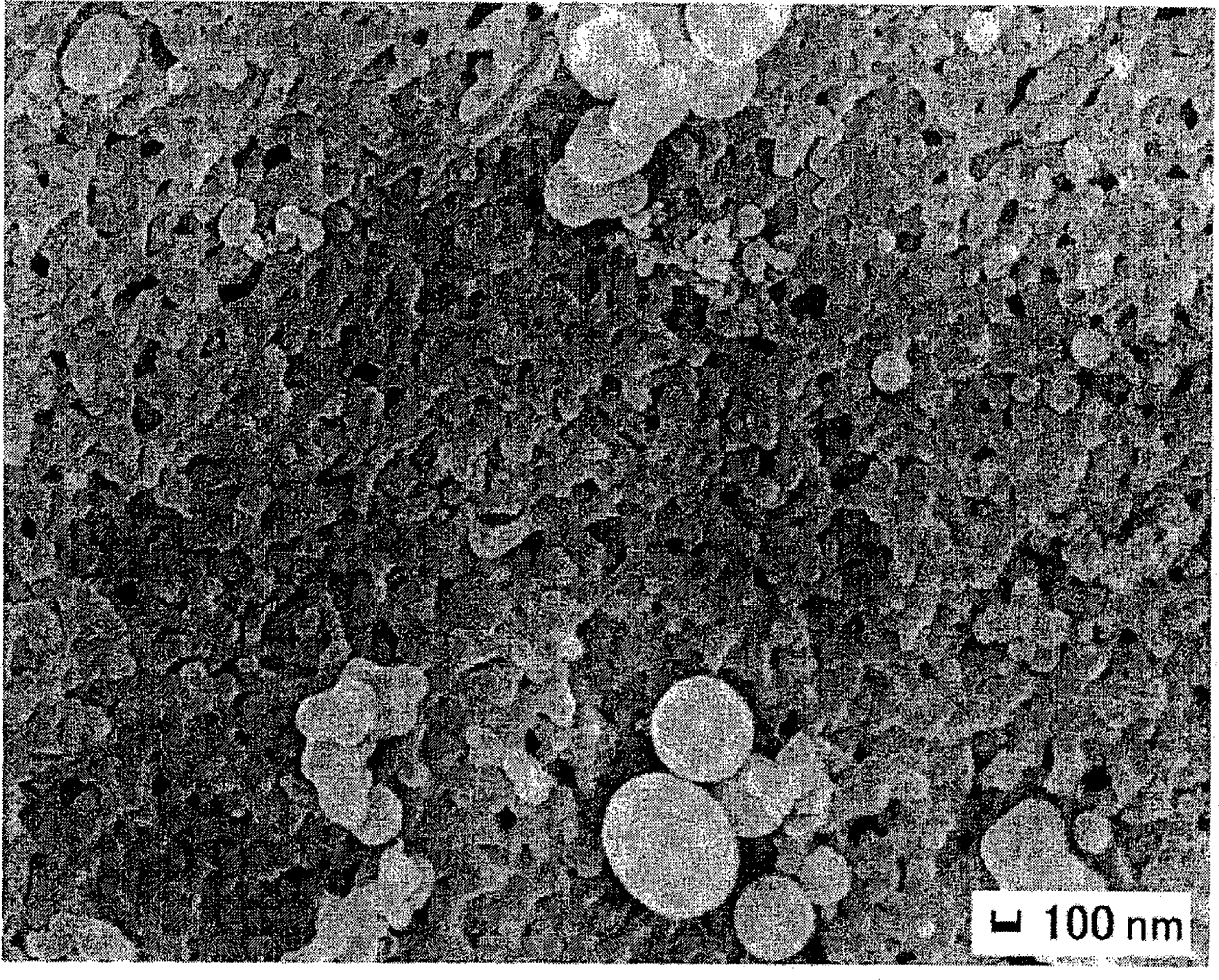

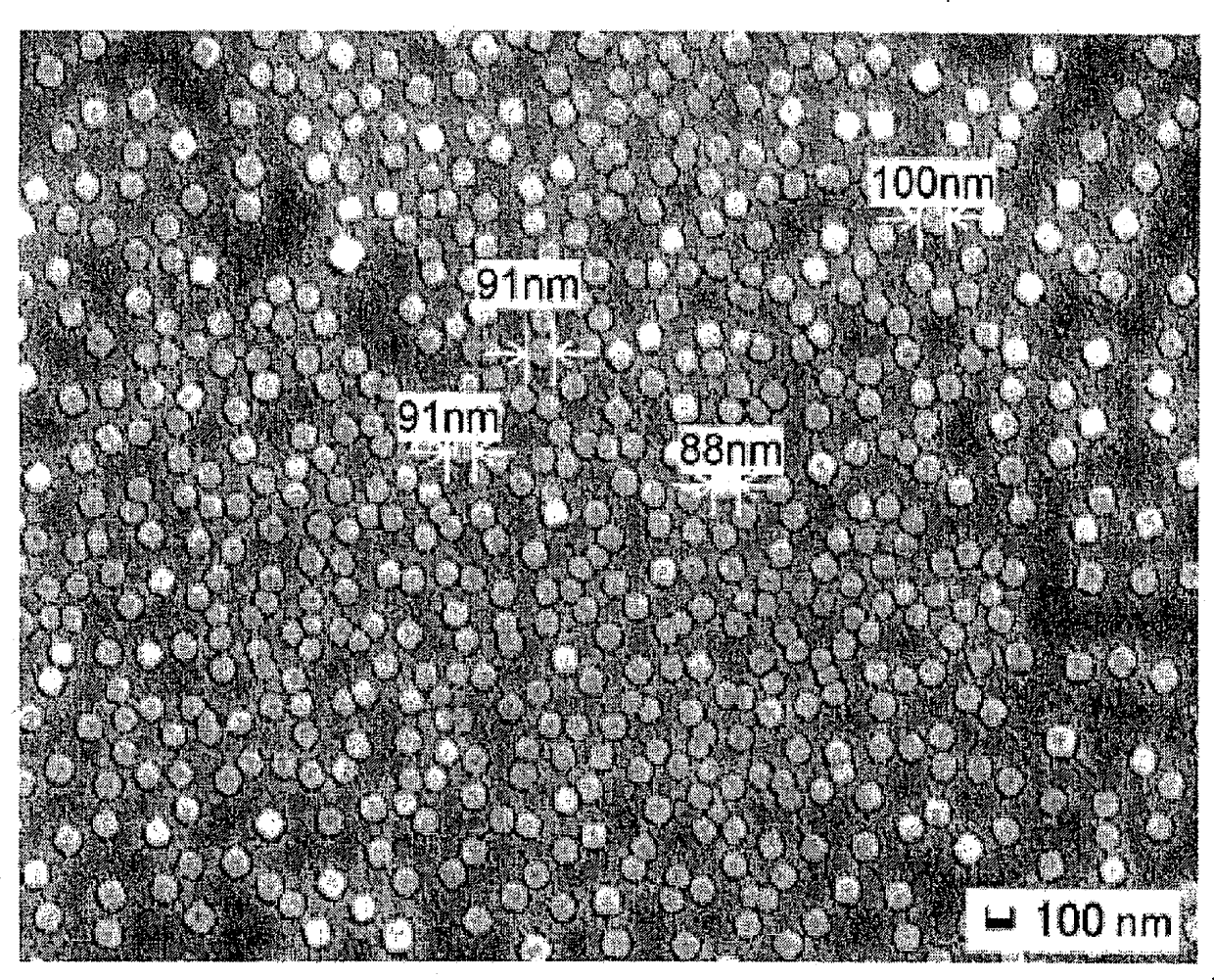

[0124] It implemented similarly to Example 1 except having set the temperature of the dissolution tank of Example 1 to 50 degreeC, and pressurized it to 0.5 MPa with nitrogen. The average particle size of the flash liquid is 12.4 μm. In addition, the average primary particle size of the PAI microparticles was 110 nm, and the coefficient of variation was 40%. Observed with a scanning electron microscope (SEM) at 30,000 magnifications, the particles are roughly spherical.

[0125] In order to confirm the reproducibility, the same operation as above was carried out. As a result, the average primary particle size of the PAI microparticles was 112 nm, and the coefficient of variation was 38%, confirming reproducibility.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average primary particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Secondary particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com