Clamping system of movable main spindle box and clamping method

A spindle box and clamping oil cylinder technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of affecting the processing quality and precision retention of parts, unable to detect clamping force, and inconvenient operation. Achieve the effects of improving processing quality and precision retention, facilitating automatic control, and reducing auxiliary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

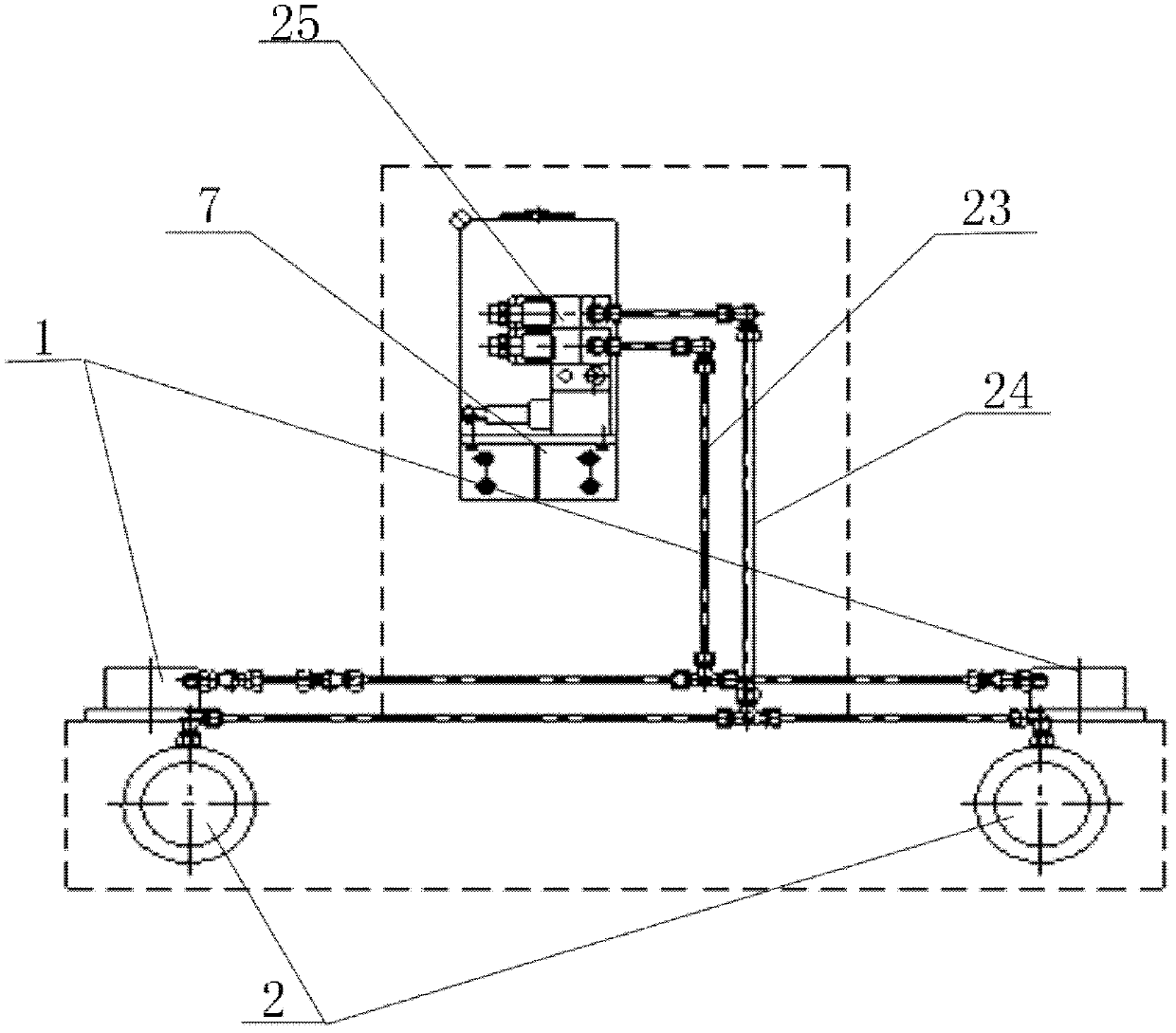

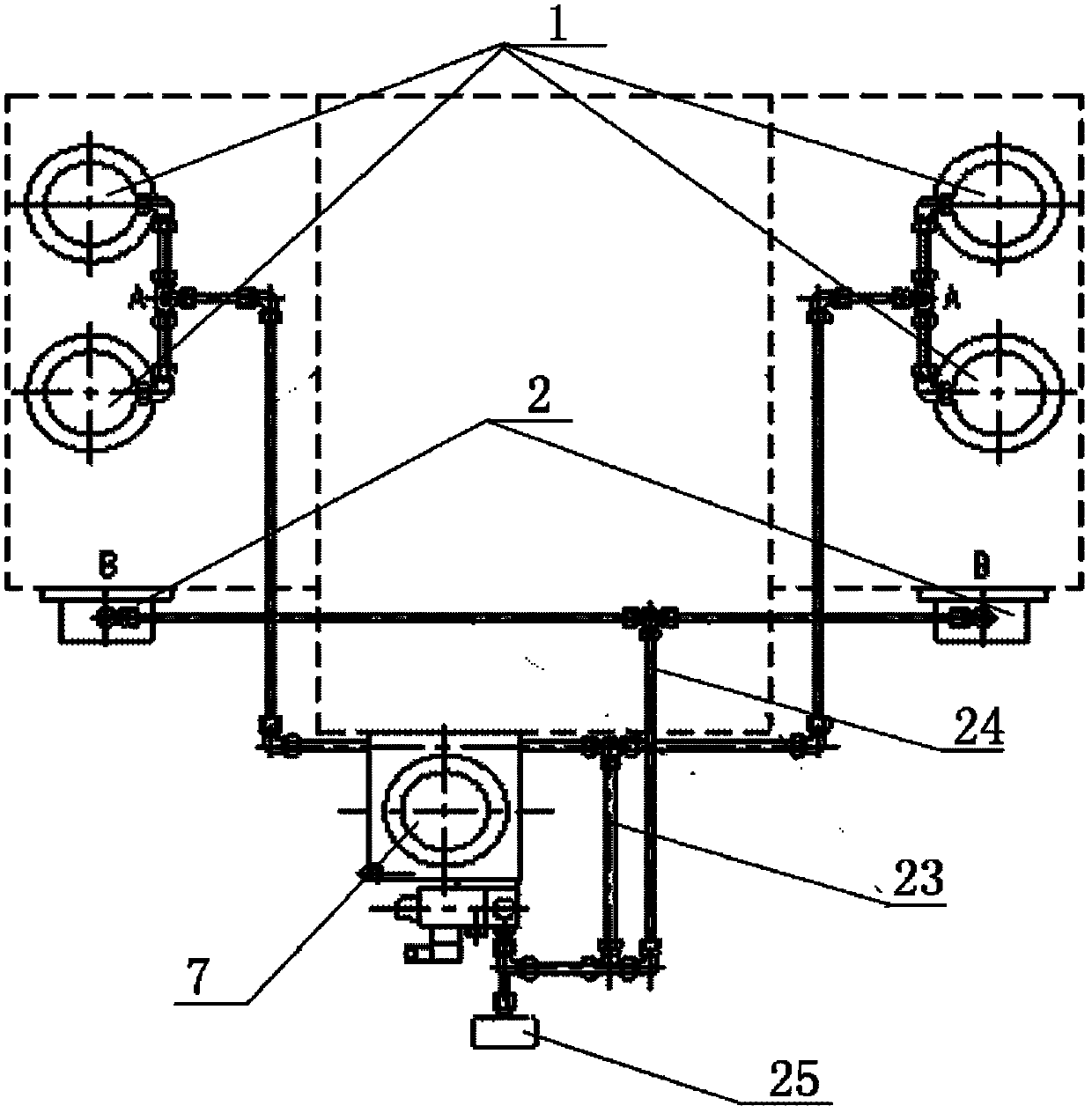

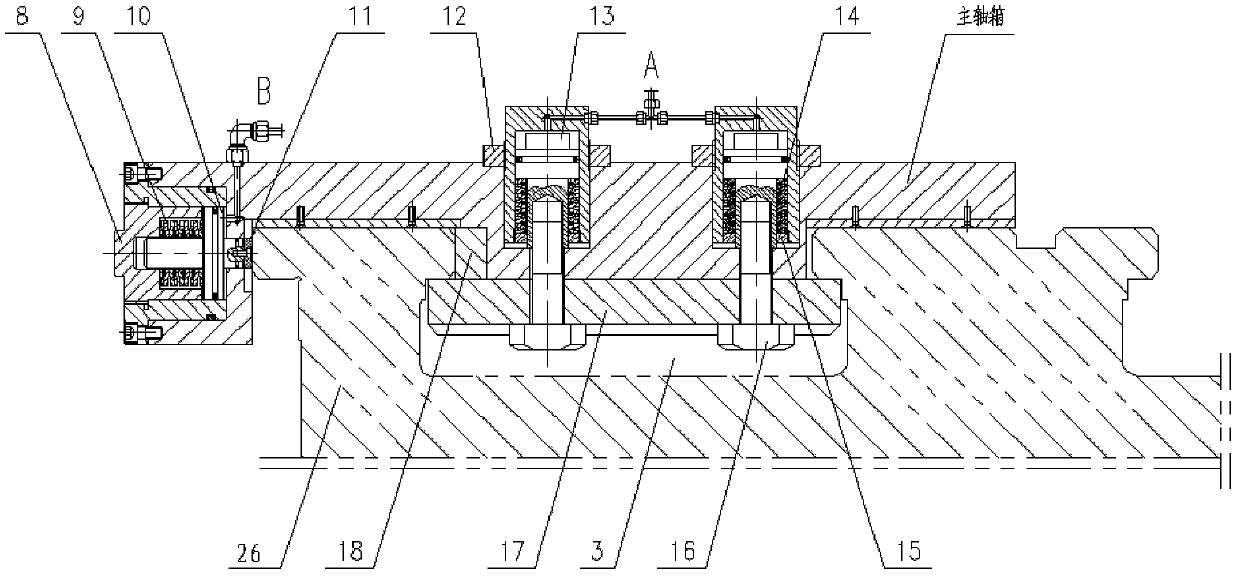

[0031] Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a clamping system for a movable spindle box includes two sets of first clamping cylinders 1 arranged in the vertical direction of the spindle box, and the first clamping cylinders include a pair of clamping cylinders; A pair of second clamping oil cylinders 2 are provided, and the first clamping oil cylinder 1 and the second clamping oil cylinder 2 are connected to each other through the first oil inlet and return pipeline 23, the second oil inlet and return pipeline 24 and the high-pressure pump station 7. Unicom, a solenoid valve group 25 is provided on the first oil inlet and return pipeline and the second oil inlet and return pipeline. By adjusting the pressure of the high-pressure pump station 7, the loosening strokes of the first clamping oil cylinder and the second oil cylinder can be adjusted.

[0032] The first clamping cylinder 1 is provided with a first disc spring 14, and the first ...

Embodiment 2

[0037] Embodiment 2: as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention also provides a clamping method for a movable headstock, comprising the following steps:

[0038] 1) Spindle box loosening steps:

[0039] The first electromagnetic reversing valve 19-1 controls the high-pressure pump station 7 to press the hydraulic oil into the first clamping cylinder 1 in the vertical direction through the first oil inlet and return pipeline 23, and the piston 13 of the first clamping cylinder goes down. The movement forces the first disc spring 14 to be compressed and deformed, and drives the T-shaped bolt 16 and the pressure plate 17 to move downward. At this time, the clamping force in the vertical direction of the spindle box disappears;

[0040] At the same time, the second electromagnetic reversing valve 19-2 controls the high-pressure pump station 7 to press the hydraulic oil into the second clamping cylinder 2 in the horizontal direction through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com