Method for producing methane through jointly opsonizing sludge by microwave and heat to improve anaerobic fermentation of low organic sludge

A sludge anaerobic fermentation and organic matter technology, applied in the field of solid waste recycling, can solve the problems of difficult anaerobic stable process treatment and disposal, difficult start-up of low organic matter sludge, unstable gas production, etc., to improve sludge production The effect of increasing the gas rate, promoting the resource utilization of low organic matter sludge, and shortening the sludge residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

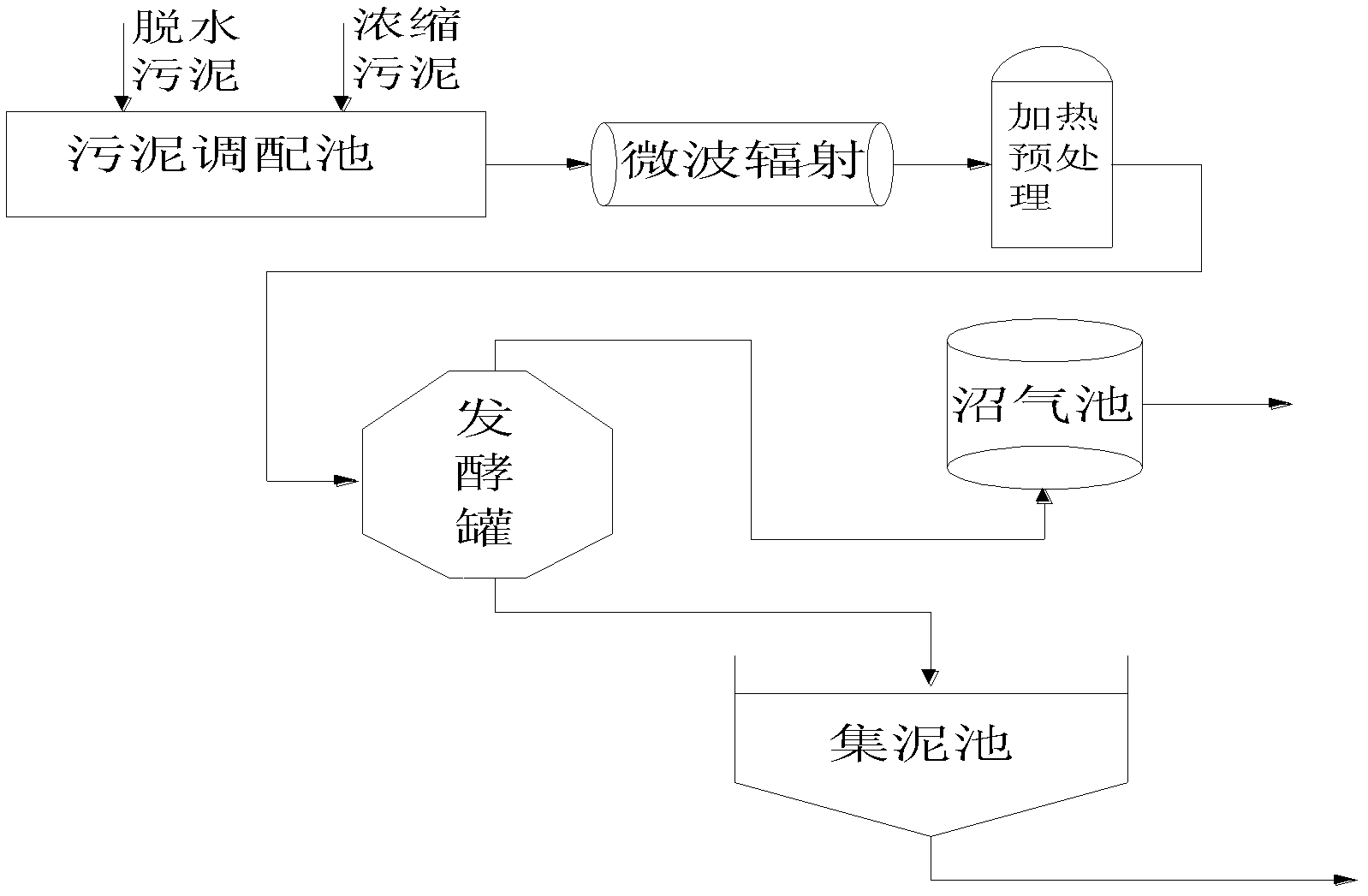

[0024] figure 1 A flow chart showing the method for improving the anaerobic fermentation of low-organic-matter sludge to produce biogas by combining microwave and heat conditioning sludge according to the present invention.

[0025] Take dewatered sludge (water content 78.91%) and thickened sludge (water content 96.17%) from a sewage treatment plant in a certain place to make mixed sludge with water content 90.0% in the sludge blending tank. At this time, its volatile Organic solids accounted for 32.5% of the total solids. Then put the above sludge into the microwave irradiation device, the microwave frequency is 2450MHz, under the condition of 1000W, it is irradiated by microwave for 1min, and then put into the heating pretreatment device, and heated at 120°C for 30min. Take 1L of the above-mentioned sludge that has been processed and put it into a fermenter with an effective volume of 20L (the sludge residence time is 20d), and discharge 1L into the sludge collection tank. ...

Embodiment 2

[0030] Take dewatered sludge (water content 79.11%) and thickened sludge (water content 97.62%) from a sewage treatment plant in a certain place to make mixed sludge with water content 85.0% in the sludge blending tank. At this time, its volatile The proportion of organic solids to total solids was 20.0%. Then put the above sludge into the microwave irradiation device, the microwave frequency is 2450MHz, microwave irradiation under the condition of 600W for 10min, then put into the heating pretreatment device, and heat at 90°C for 60min. Take 1L of the above-mentioned sludge that has been processed and put it into a fermenter with an effective volume of 25L (the sludge residence time is 25d), and discharge 1L into the sludge collection tank. The gas is collected through the digester every day, and the temperature is controlled at 35±2°C, the pH is automatically adjusted to 7.5±0.5, and the speed is controlled at 150rpm. After 2 to 3 cycles of continuous operation (ie 50 to 75...

Embodiment 3

[0035] Take dewatered sludge (water content 78.11%) and thickened sludge (water content 98.35%) from a sewage treatment plant in a certain place to make mixed sludge with water content 95.0% in the sludge blending tank. At this time, its volatile The proportion of organic solids to total solids was 45.0%. Then put the above sludge into the microwave irradiation device, the microwave frequency is 2450MHz, under the condition of 100W, it is irradiated by microwave for 20min, and then put into the thermal pretreatment device, and heated at 170℃ for 10min. Take 1L of the above-mentioned sludge that has been processed and put it into a 30L effective volume fermenter (sludge residence time is 30d), and discharge 1L into the sludge collection tank. The gas is collected through the biogas digester every day, and the temperature is controlled at 55±2°C, the pH is automatically adjusted to 7.5±0.5, and the speed is controlled at 50rpm. After 2 to 3 cycles of continuous operation (ie 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com