System and method for producing methane through fermenting of mixed raw material

A technology for mixing raw materials and biogas, which is applied in biochemical equipment and methods, fermentation, gas production bioreactors, etc., can solve problems such as the effect of fermentation effect, and achieve the benefits of subsequent anaerobic digestion, saving production water, and improving gas production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

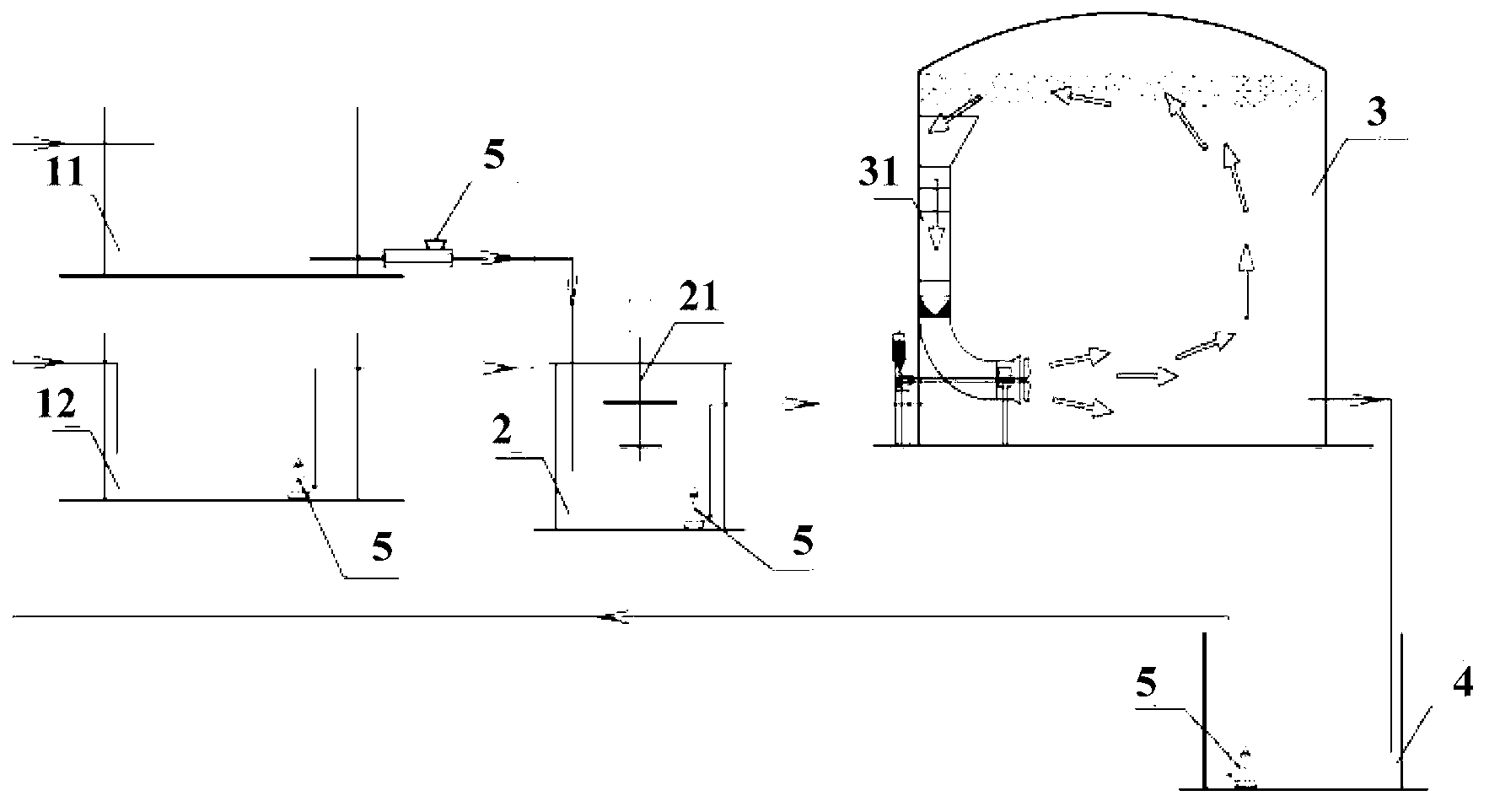

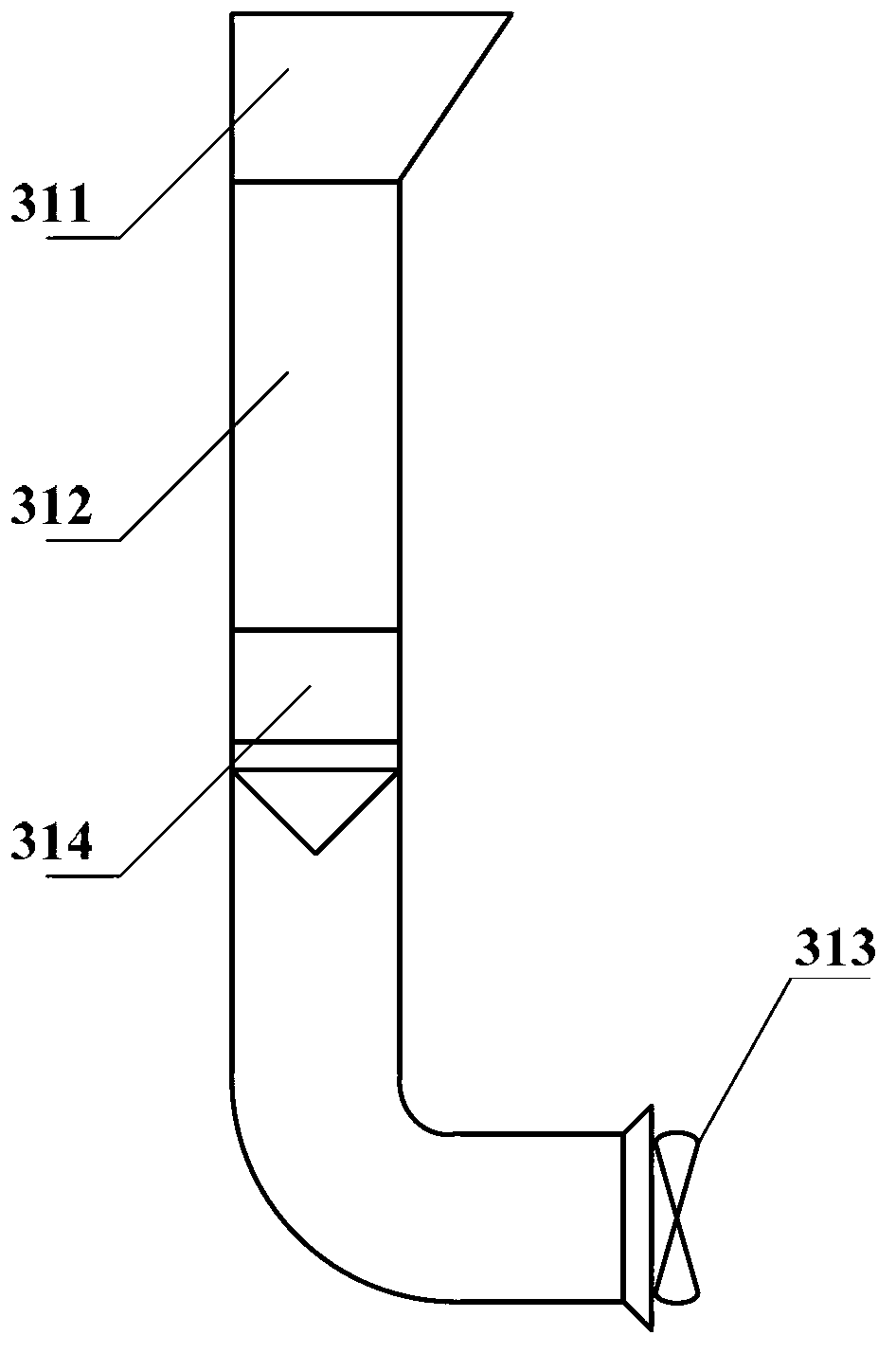

[0023] Such as figure 1 , figure 2 As shown, a system for producing biogas by fermentation of mixed raw materials is manufactured.

[0024] figure 1 It is a schematic diagram of the system structure for producing biogas by fermentation of mixed raw materials. A system for producing biogas by mixing raw materials by fermentation, including a raw material pool, a mixing pool 2, an anaerobic fermentation tank 3, and a sedimentation tank 4 connected sequentially by sealed pipes; a water supply / material device 5 is installed in the raw material pool, and a stirring device 21 is installed in the mixing tank With water / feeding device5. The raw material pool includes a carbon-rich biological raw material pool 11 and a nitrogen-rich biological raw material pool 12 respectively connected to the mixing pool 2; a water delivery / material device 5 is installed in the sedimentation tank 4, and is respectively connected to the carbon-rich biological raw material pool 11 and the nitrogen-r...

Embodiment 2

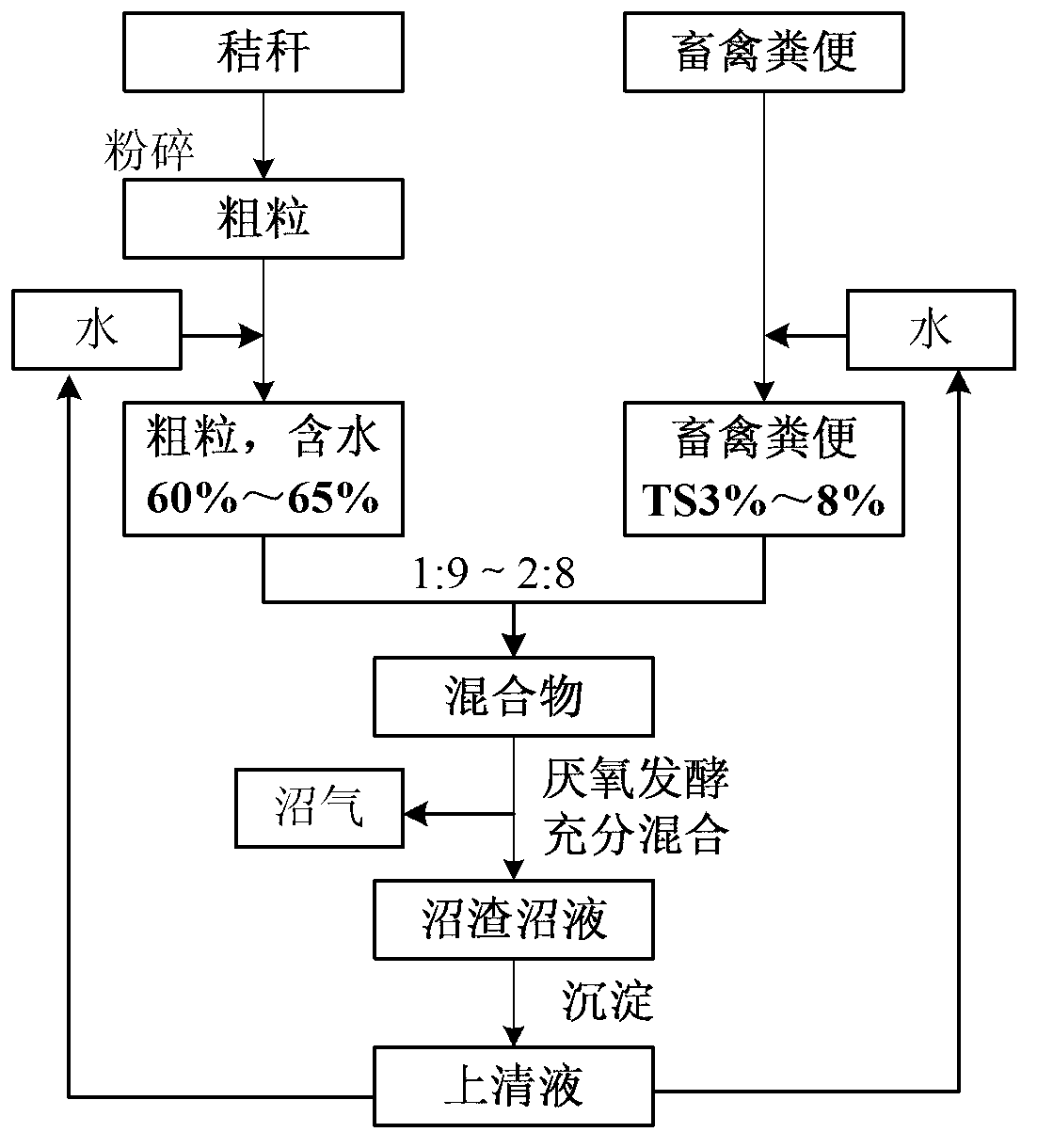

[0028] The system for producing biogas by fermentation of mixed raw materials described in Example 1 is used to produce biogas, and the schematic diagram of its process flow is as follows image 3 .

[0029] 1. Biological raw materials:

[0030] The carbon-rich biological raw material is natural dried ordinary farmland straw, crushed to 3mm ~ 10mm coarse grain, and the moisture content is measured by conventional sample drying method; the nitrogen-rich biological raw material is selected from rural livestock and poultry manure, and the conventional sample drying method is dried to measure the moisture content .

[0031] 2. Production process

[0032] Take 16Kg (DW) of coarse grain straw and put it into the carbon-rich biological raw material pool 11, add water to adjust to a moisture content of 60% to 65%; take 150Kg (DW) of livestock and poultry manure and put it into the nitrogen-rich biological raw material pool 12, add water to adjust to the TS concentration 3% to 8%; t...

Embodiment 3

[0034] The system for producing biogas by fermenting mixed raw materials described in Example 1 is used to produce biogas. The same parts as in Example 2 will not be repeated, except that the carbon-rich biological raw materials are pretreated.

[0035] Bacterial Mixture: Contains Trametes hirsuta and Trametes versicolor and the activator yeast powder required for the growth of the strains.

[0036] The pretreatment process of carbon-rich biological raw materials is as follows: take 16Kg (DW) of straw coarse grains and put them into the carbon-rich biological raw material pool 11, add water to adjust to a moisture content of 60% to 65%; W / W); Fermentation after inoculation for 3 to 4 days at a temperature of 25°C to 40°C.

[0037] After the treatment, it is sent to the mixing tank 2 to mix with the prepared livestock and poultry manure at a ratio of 1:9 to 2:8 (DW / DW) to continue the subsequent process steps.

[0038] The detailed pretreatment process adopts the bio-chemical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com