Livestock and poultry manure anaerobic fermentation device with biogas slurry reflux pipeline

An anaerobic fermentation, livestock and poultry manure technology, applied in biological sludge treatment, waste fuel, etc., can solve the problems of biogas slurry cannot be used directly, atmospheric and natural secondary pollution, etc., to reduce secondary pollution, reduce Energy consumption, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

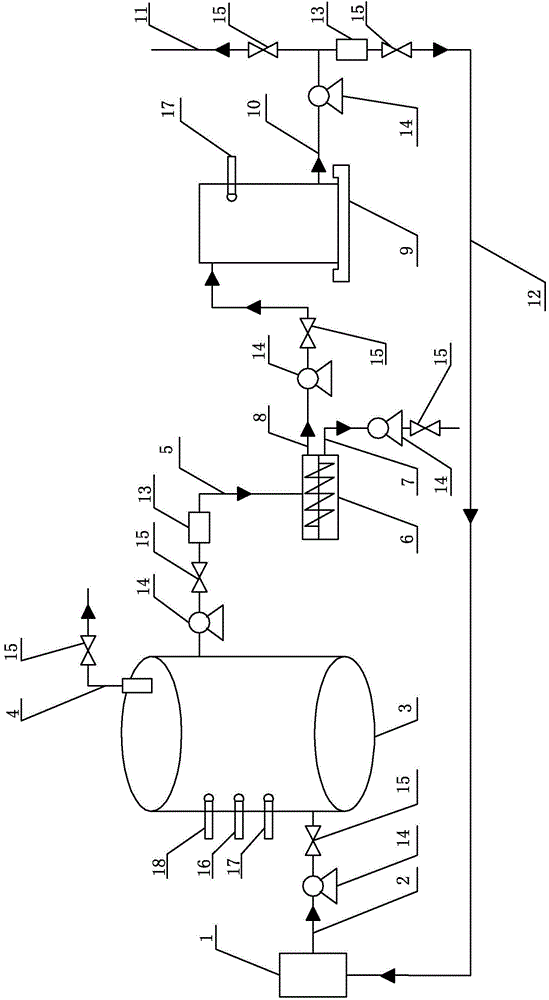

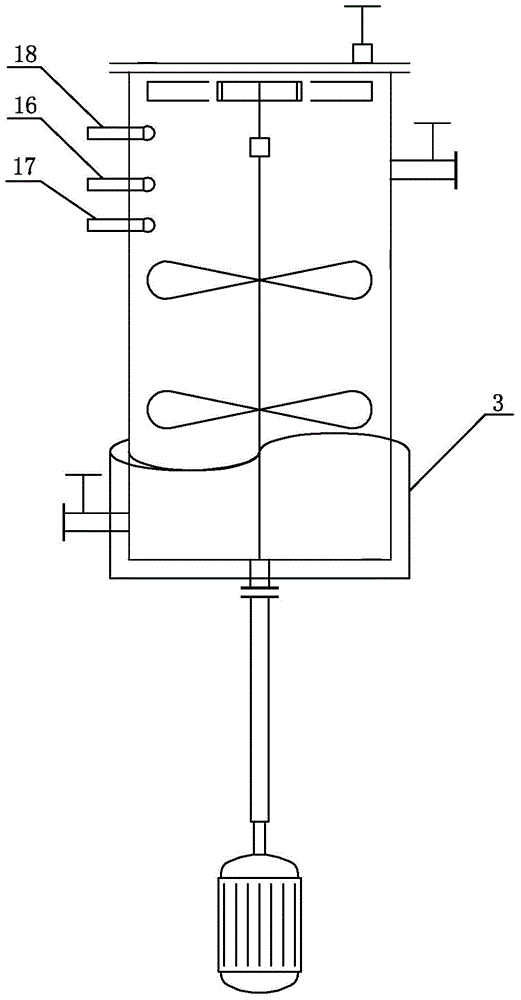

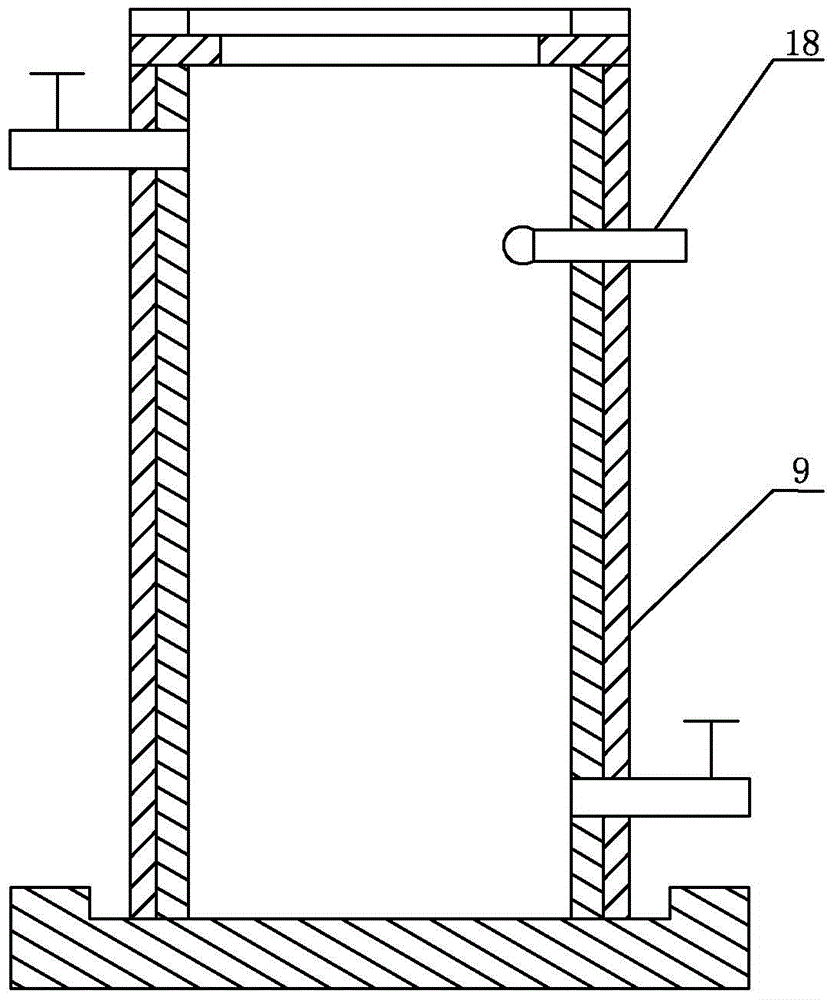

[0012] Specific implementation mode one: combine Figure 1 to Figure 3 To illustrate this embodiment, a livestock and poultry manure anaerobic fermentation device with a biogas slurry return pipeline described in this embodiment includes a feed device 1, a feed pipeline 2, an anaerobic fermentation tank 3, a biogas pipeline 4, and a digestate pipeline 5. Solid-liquid separator 6, biogas residue pipeline 7, biogas slurry first pipeline 8, biogas slurry storage tank 9, biogas slurry second pipeline 10, biogas slurry third pipeline 11, biogas slurry return pipeline 12, feeding device 1 The anaerobic fermentation tank 3 is communicated with the anaerobic fermentation tank 3 through the feed pipeline 2, and the anaerobic fermentation tank 3 is communicated with a biogas pipeline 4. It is connected with a biogas residue pipeline 7, and the solid-liquid separator 6 is also connected with a biogas slurry storage tank 9 through a biogas slurry first pipeline 8, and the biogas slurry st...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the anaerobic fermentation device described in this embodiment also includes two flow meters 13, multiple pumps 14 and multiple valves 15, feed pipeline 2, digestate pipeline 5, biogas residue pipeline 7 and biogas slurry first One pipeline 8 is provided with a pump 14 and a valve 15, the second biogas slurry pipeline 10 is provided with a pump 14, the biogas pipeline 4, the third biogas slurry pipeline 11 and the biogas slurry return pipeline 12 are respectively provided with a valve 15. A flow meter 13 is installed on the digestive liquid pipeline 5 and the biogas slurry return pipeline 12 respectively. So set, the flow meter 13 is used to adjust the flow of the material liquid. Other compositions and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination Figure 1 to Figure 3 Illustrate this embodiment, the anaerobic fermentation device described in this embodiment also comprises pH meter 16, temperature sensor 17 and two material level sensors 18, is equipped with a pH meter 16, a temperature sensor 18 on the outer wall of anaerobic fermentation tank 3. A sensor 17 and a material level sensor 18, a material level sensor 18 is inserted on the outer wall of the biogas slurry storage tank 9. Set in this way, the pH meter 16 can measure the pH value of the feed liquid in the anaerobic fermentation tank 3, and the temperature sensor 17 can measure the fermentation temperature in the anaerobic fermentation tank 3, so that the fermentation temperature can be controlled under a suitable condition. It can measure the liquid level of the feed liquid, so that the height of the feed liquid is suitable, so as to achieve the purpose of real-time monitoring. Other compositions and conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com