Preparation method of 2-aminophenyl phenyl sulfide

A technology of aminodiphenyl sulfide and diaminodiphenyl sulfide, which is applied in the field of synthesis of 2-aminodiphenyl sulfide, can solve the problems of strong thiophenol odor, environmental pollution, and high price of starting materials, and achieve low cost , easy to obtain raw materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

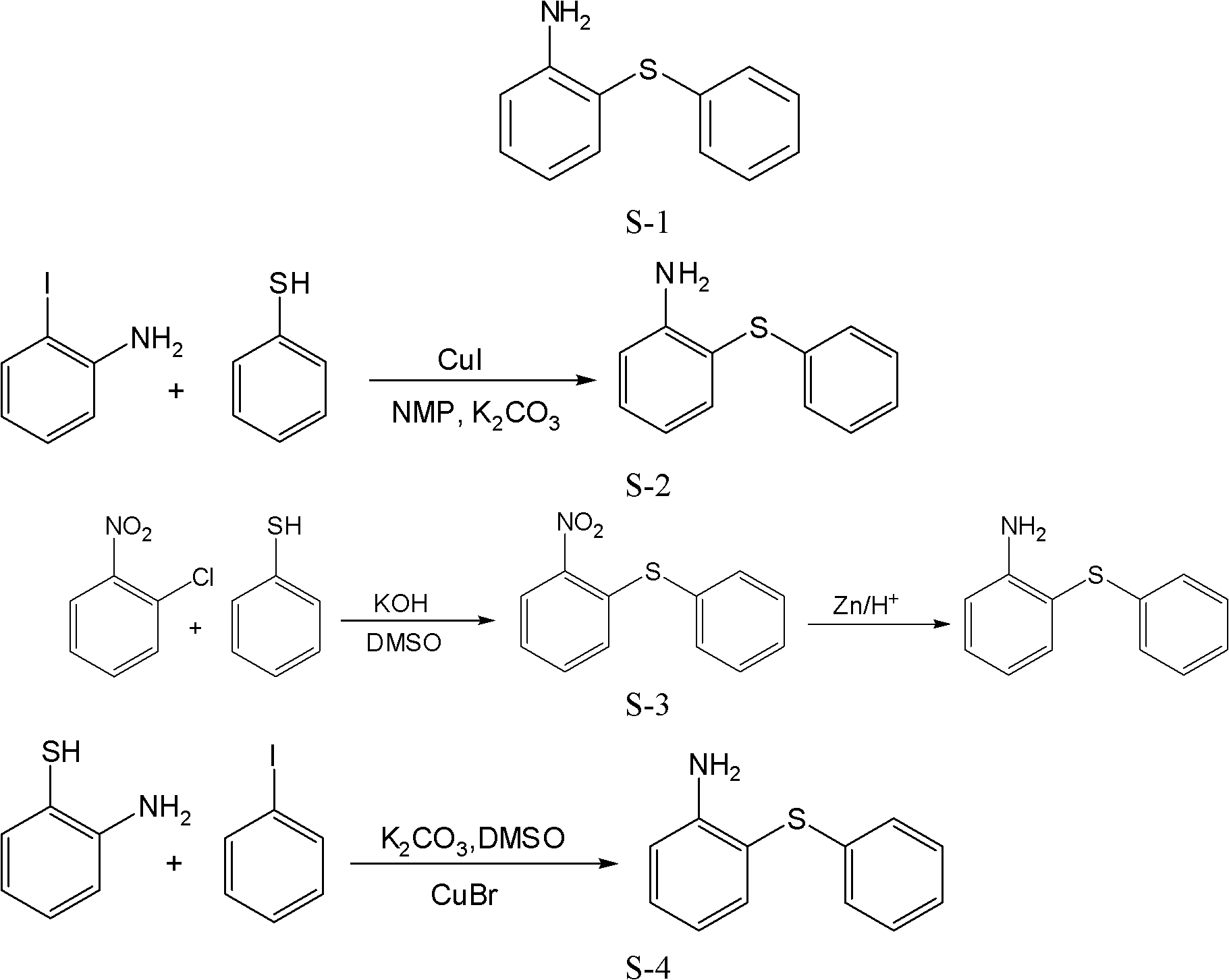

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1, a kind of preparation method of 2-amino diphenyl sulfide, take o-nitroaniline, hydrochloric acid, sodium nitrite, sodium sulfide, acetic anhydride, ethanol, sodium hydroxide etc. as raw materials, carry out the following steps successively:

[0044] Step 1), prepare diazonium salt:

[0045] 13.8g (0.1mol) of o-nitroaniline, 73g of hydrochloric acid solution (11g, 0.3mol) with a mass solubility of 15% were put into a 250ml flask, cooled to 5°C, and 30ml of aqueous sodium nitrite ( 7.9 g, 0.115 mol), adjust the dropping rate to keep the reaction temperature at 5-10 °C, drop after 2 h, continue to stir at 5 °C for 30 min after the dropping is completed, and stop the reaction.

[0046] Step 2), prepare 2,2'-diaminodiphenyl sulfide:

[0047] 150ml of Na with a mass concentration of 17.5% 2S solution (0.4mol) and 12g (0.3mol) NaOH were put into a 500ml flask, heated to 45°C, and all the diazonium salt solutions obtained in step 1) were added dropwise with stir...

Embodiment 2~10

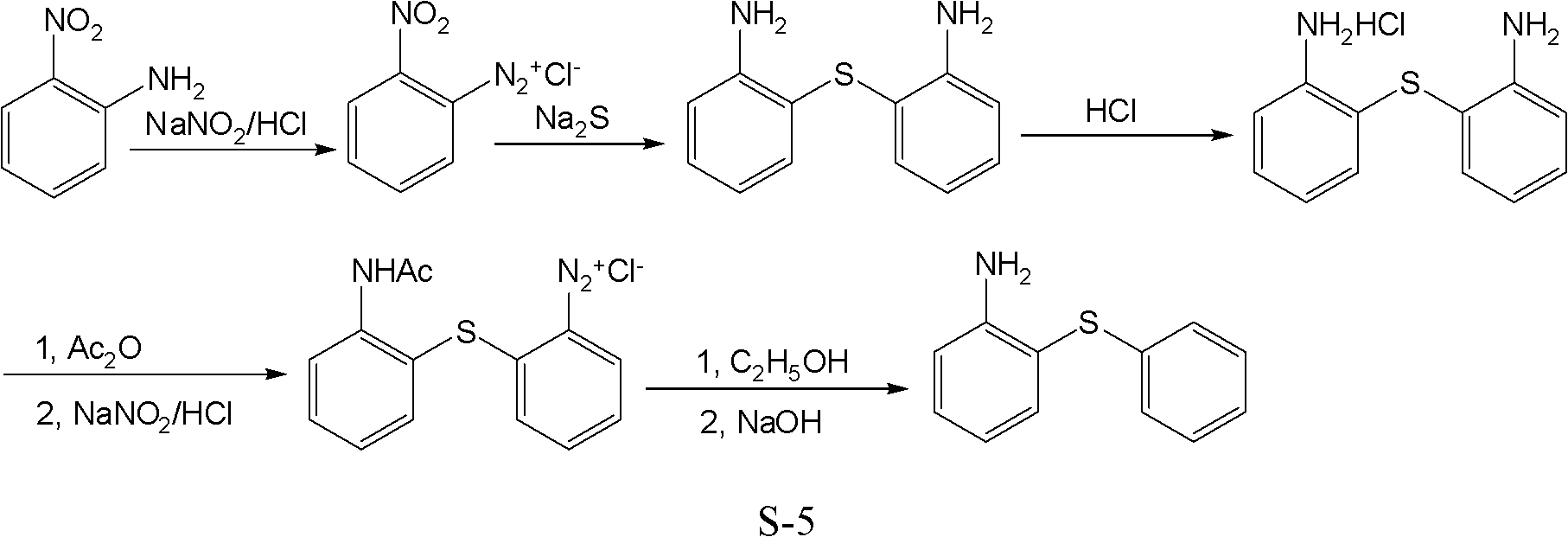

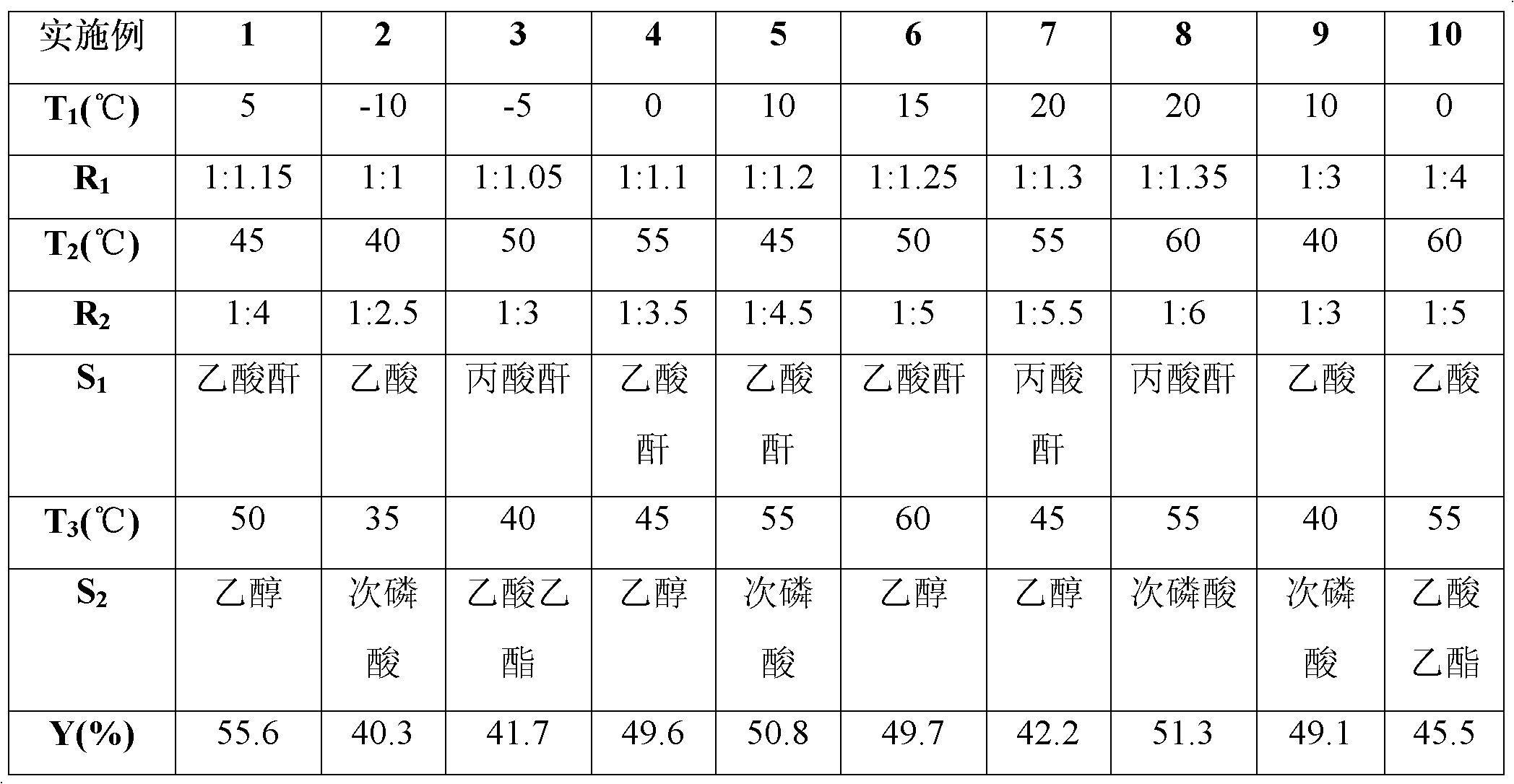

[0053] Change the following reaction conditions in steps 1) to 4) of Example 1:

[0054] In step 1), the diazotization reaction temperature (abbreviated as T 1 ), the mol ratio of o-nitroaniline and sodium nitrite in step 1) (referred to as R 1 ), step 2) in the thioetherification reaction temperature (referred to as T 2 ), the mol ratio of o-nitroaniline and sodium sulfide in step 2) (referred to as R 2 ), step 3) in acylation reaction reagent (referred to as S 1 ), step 4) in the denitrification reaction temperature (referred to as T 3 ), step 4) in the denitrification reaction reagent (referred to as S 2 ) to obtain Examples 2 to 10, and the molar ratios between the remaining reaction raw materials are the same as those of Example 1; thereby obtaining the yield of the corresponding 2-aminodiphenyl sulfide (referred to as Y). The specific content and data results are shown in Table 1.

[0055] Table 1

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com