Preparation method of phosphonitrile flame retardant

The technology of a phosphazene flame retardant, hexachlorocyclotriphosphazene, is applied in the field of preparing materials by chemical synthesis methods, and achieves the effect of reducing the number of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

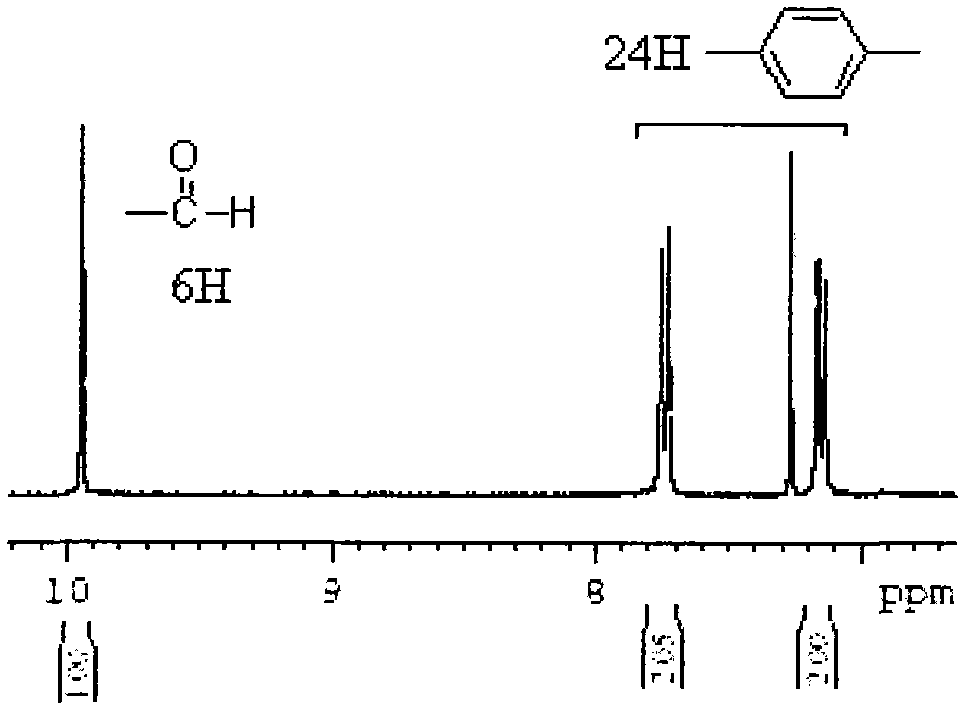

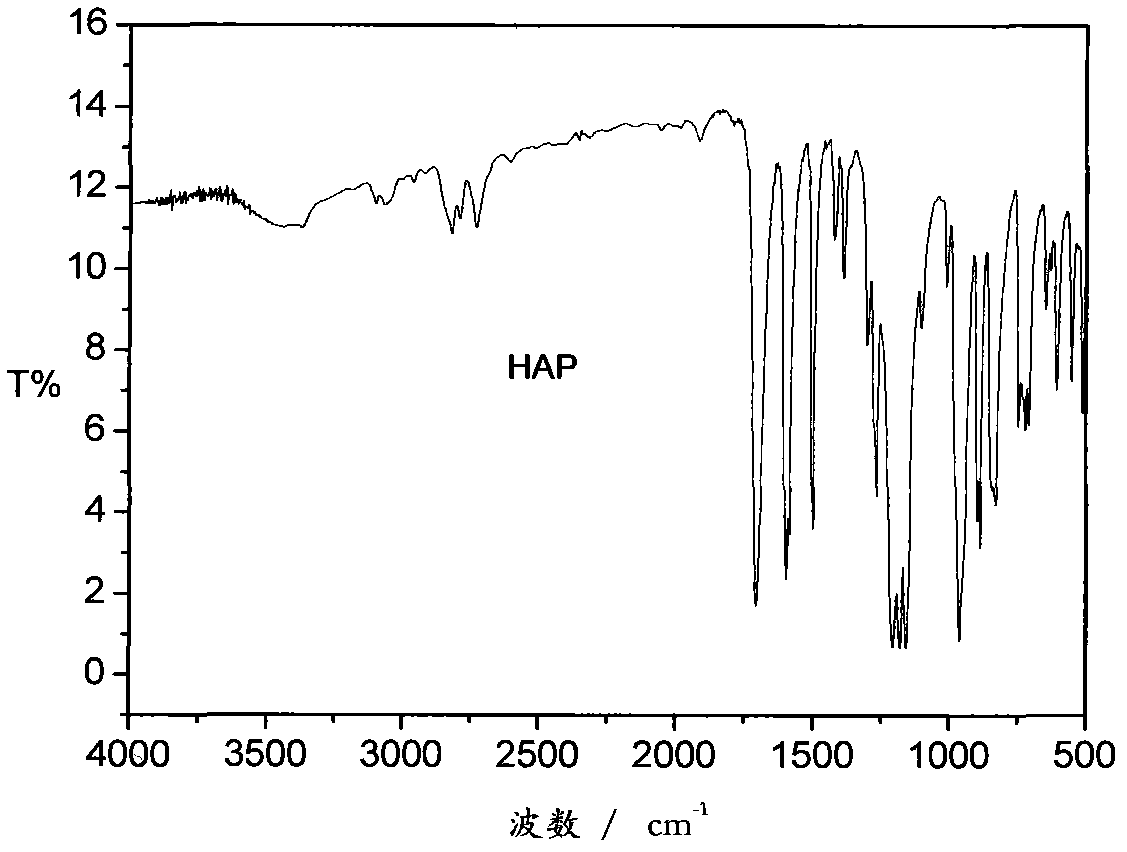

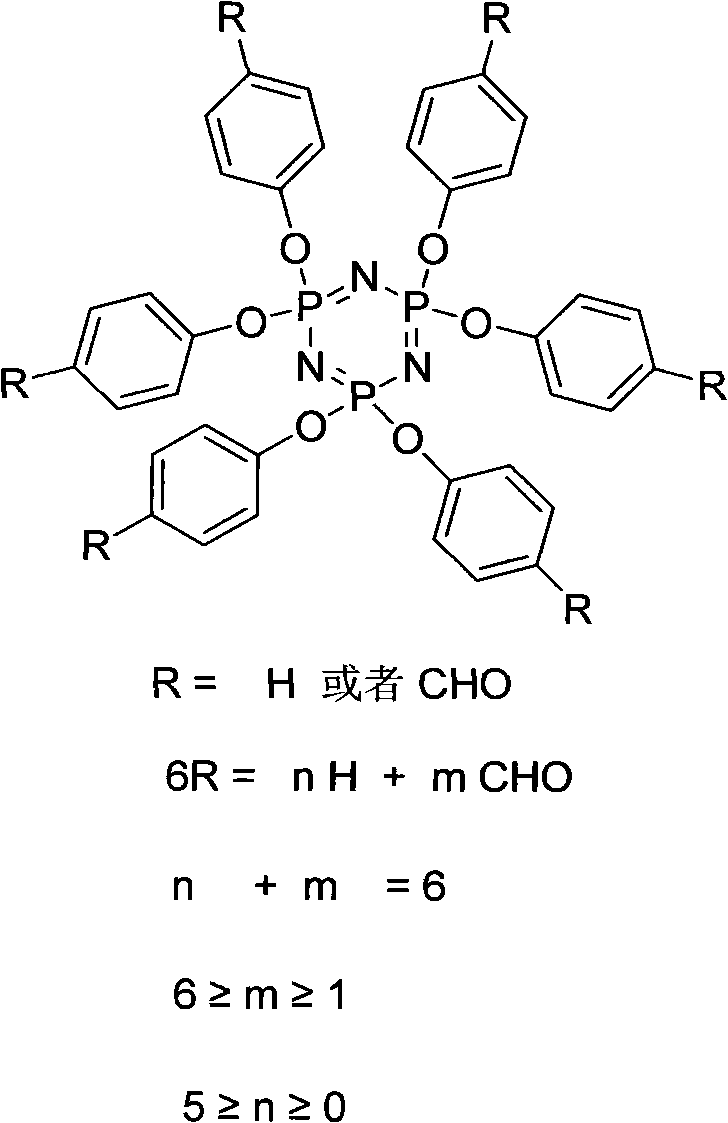

[0017] Example 1 Add 348g of hexachlorocyclotriphosphazene and 805g of p-hydroxybenzaldehyde into 2000g of toluene, add 7g of tetramethylammonium bromide, keep the reaction temperature at 108°C under stirring conditions, react for 24 hours, and add alkali to the reaction system Stir the water for washing, keep the temperature at 80°C, wash for 0.5 hours, let stand to separate, remove the water layer, add 300g of water to the organic phase for washing, keep the temperature at 80°C, wash for 0.5 hours, let stand to separate, remove the water layer, washed with water three times repeatedly, and the organic solvent was distilled off to obtain 848.9 g of product HAP with a purity of 98.6%.

Embodiment 2

[0018] Example 2 Add 348g of hexachlorocyclotriphosphazene and 805g of p-hydroxybenzaldehyde into 2000g of chlorobenzene, add 7g of tetramethylammonium bromide, keep the reaction temperature at 130°C under stirring conditions, react for 24 hours, and add Wash with alkaline water, keep the temperature at 80°C, wash for 0.5 hours, let stand to separate, remove the water layer, add 600g of water to the organic phase for washing, keep the temperature at 80°C, wash for 0.5 hours, let stand to separate, remove After the aqueous layer was washed with water three times, the organic solvent was distilled off to obtain 852.4 g of product HAP with a purity of 99.0%.

Embodiment 3

[0019] Example 3 Add 348g of hexachlorocyclotriphosphazene, 610g of p-hydroxybenzaldehyde, and 103g of phenol into 2000g of toluene, add 15g of tetraethylammonium bromide, keep the reaction temperature at 108°C under stirring conditions, and react for 24 hours. Add alkaline water and stir to wash, keep the temperature at 80°C, wash for 0.5 hours, let stand to separate, remove the water layer, add 500g water to the organic phase to wash, keep the temperature at 80°C, wash for 0.5 hours, let stand and separate , after removing the water layer, repeated washing with water 3 times, and distilled off the organic solvent to obtain 819.7g product HAP with a purity of 98.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com