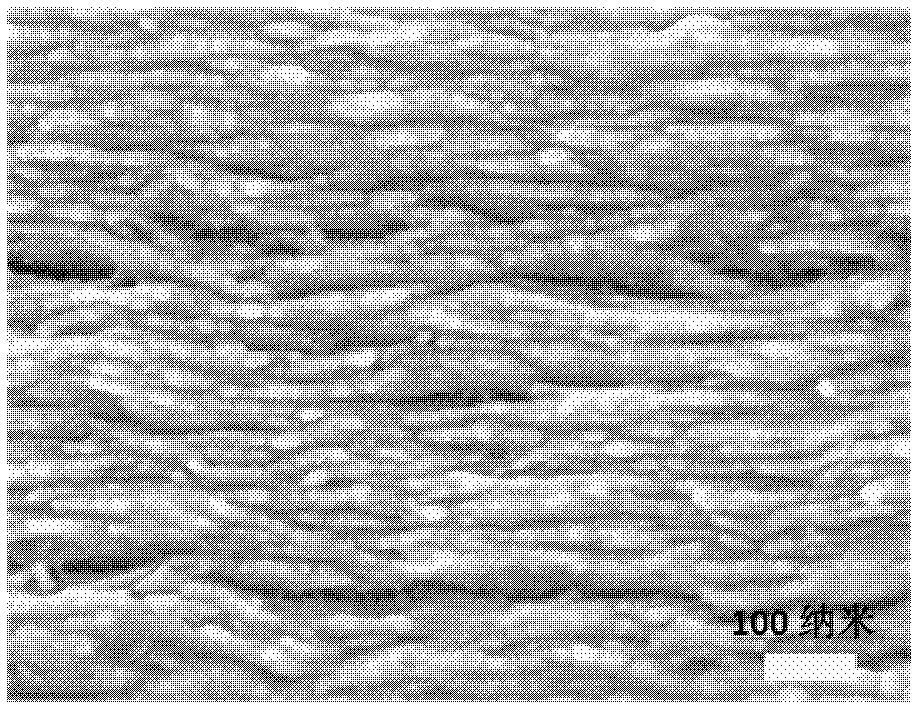

Preparing method of biomimetic laminated high-strength composite hydrogel film

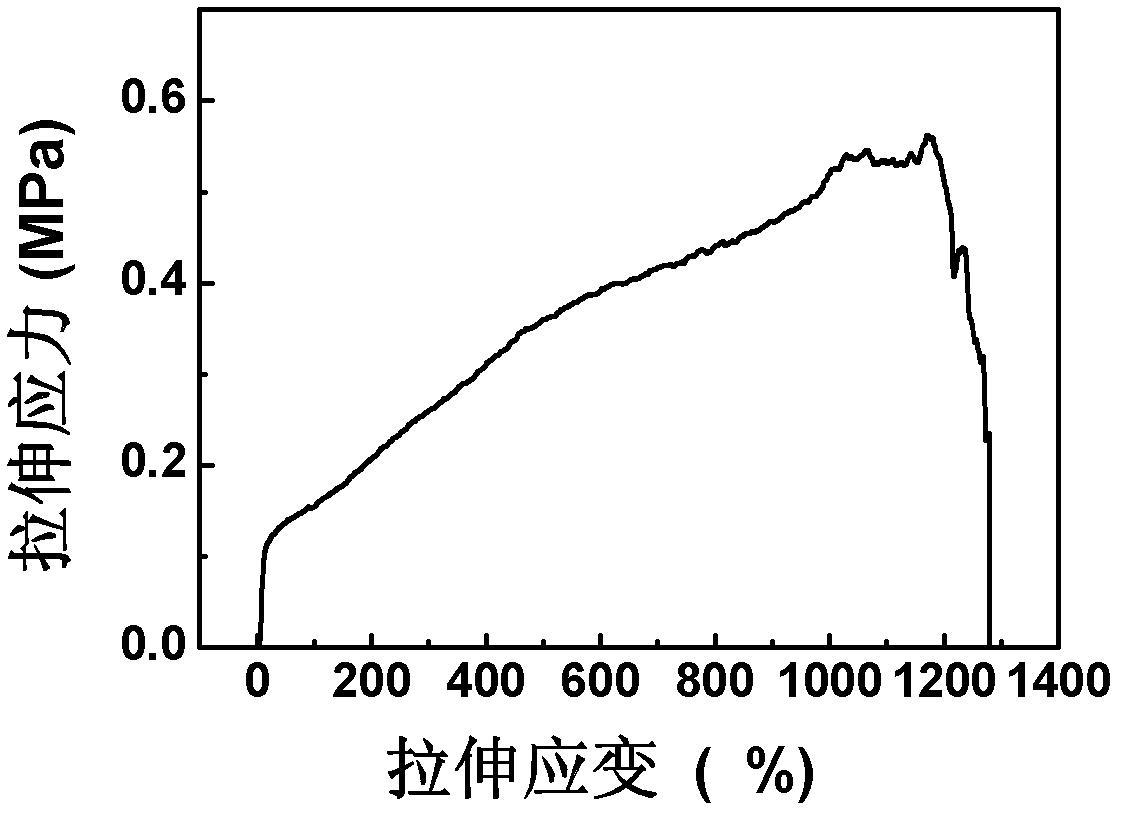

A composite hydrogel, high-strength technology, applied in the field of polymer hydrogel, can solve problems such as poor mechanical strength, achieve high tensile modulus, simple preparation method, and high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Dissolving synthetic hectorite nanosheets with a diameter of 10-60 nanometers in water, ultrasonication for 30 minutes, and stirring for 5 hours to obtain a uniform synthetic hectorite aqueous solution, and then adding N-isopropylpropylene Amide monomer, stirred for 30 minutes to dissolve N-isopropylacrylamide, then added initiator 2,2-diethoxyacetophenone, stirred for 1 hour to dissolve the initiator, and finally obtained synthetic hectorite, N- Aqueous solution of isopropylacrylamide and initiator. Wherein the mass percentage of N-isopropylacrylamide is 2.67%, the mass percentage of synthetic hectorite is 0.6%, and the mass percentage of 2,2-diethoxyacetophenone is 0.27% , and the balance is water.

[0033](2) Pour the mixed solution obtained in step (1) onto a microporous filter membrane with a pore size of 0.1 micron and vacuum filter to obtain N-isopropylacrylamide, synthetic hectorite, 2,2-diethoxy A filter cake of acetophenone and water. Then irradiate the...

Embodiment 2

[0036] (1) Dissolving synthetic hectorite nanosheets with a diameter of 10-60 nanometers in water, ultrasonicating for 30 minutes, and stirring for 5 hours to obtain a uniform synthetic hectorite aqueous solution, then adding acrylamide monomer, stirring Dissolve the acrylamide in 30 minutes, then add the initiator 2,2-diethoxyacetophenone, stir for 1 hour to dissolve the initiator, and finally obtain an aqueous solution containing synthetic hectorite, acrylamide and the initiator. Wherein the mass percentage of acrylamide is 2.67%, the mass percentage of synthetic hectorite is 0.6%, the mass percentage of 2,2-diethoxyacetophenone is 0.1%, and the balance is water .

[0037] (2) Pour the mixed solution obtained in step (1) onto a filter membrane with a pore size of 0.05 micron for vacuum filtration to obtain a compound containing acrylamide, synthetic hectorite, 2,2-diethoxyacetophenone and water filter cake. The water content in the filter cake is further reduced by slow vo...

Embodiment 3

[0040] (1) Dissolving natural montmorillonite nanosheets with a diameter of 50-200 nanometers in water, ultrasonication for 30 minutes, and stirring for 24 hours to obtain a uniform natural montmorillonite aqueous solution, and then adding N,N-dimethylpropylene Amide monomer, stir for 30 minutes to dissolve N,N-dimethylacrylamide, then add the initiator 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone, stir for 30 minutes to dissolve and initiate agent, and finally obtain an aqueous solution containing natural montmorillonite, N, N-dimethylacrylamide, and an initiator. Wherein the mass percent composition of N,N-dimethylacrylamide monomer is 8%, the mass percent composition of natural montmorillonite is 0.6%, 2-hydroxyl-4'-(2-hydroxyethoxy)- The mass percent composition of 2-methylpropiophenone is 0.5%, and the balance is water.

[0041] (2) Pour the mixed solution obtained in step (1) onto a microporous filter membrane with a pore size of 0.22 microns for vacuum filtrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com