Preparation method of montmorillonoid/polylactic acid nano composite material

A nanocomposite material, polylactic acid technology, applied in the field of preparation of montmorillonite/polylactic acid nanocomposite materials, can solve the problems of low molecular weight and narrow application range of polylactic acid, and achieve simple and effective preparation methods, wide application range, and improved The effect of dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

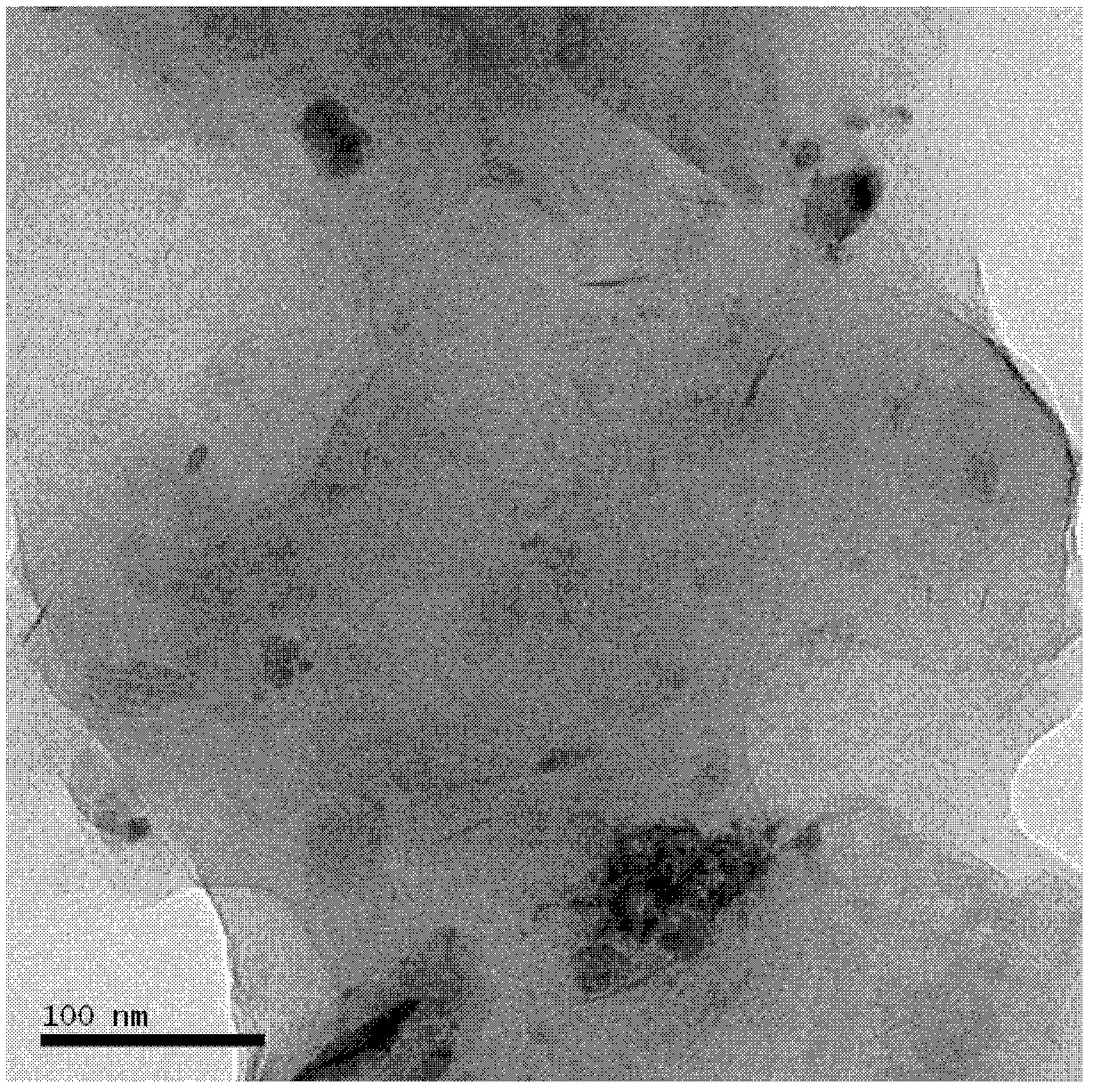

Image

Examples

Embodiment 1

[0022] The 300ml dispersion containing 20g of the modified MMT is filtered out of the zirconium balls, and the filtered dispersion is put into a 2L stainless steel stirrer with cooling water, and then 200g of PLA powder is also added to the stainless steel stirrer. After stirring at a high speed of 3000 rpm for 3 minutes, pour out the obtained mixed solution and let it rest for 30 minutes, remove the completely clear liquid in the upper layer, and put it into a drying oven for 24 hours under vacuum at 50°C. The dry mixture obtained above and 2 g of tris(2,4-di-tert-butylphenyl) phosphite were added into an internal mixer, and melt-blended at 180° C. for 3 minutes to obtain a product.

Embodiment 2

[0024] The 300ml dispersion that contains the modified MMT of 10g is filtered off the zirconium balls, and the dispersion that is filtered is put back into a 2L stainless steel stirrer with cooling water, and then the PLA powder of 200g is also added in this stainless steel stirrer, After stirring at a high speed of 3000 rpm for 10 minutes, pour out the obtained mixed solution and let it stand for 30 minutes, remove the completely clear liquid in the upper layer, and put it into a drying oven for 36 hours under vacuum at 60°C. The dry mixture obtained above and 2 g of phenylene diisodecyl phosphite were added into an internal mixer, and melt-blended at 190° C. for 10 minutes to obtain a product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com