Preparation method of reactive dye printing paste for printing fine patterns

A printing paste and reactive dye technology, applied in the textile field, can solve the problems of poor rheology and permeability of sodium alginate paste, edge bleeding, poor hand feeling, etc., achieve good rheology and permeability, increase added value, Improvement of screen penetration and depaste rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

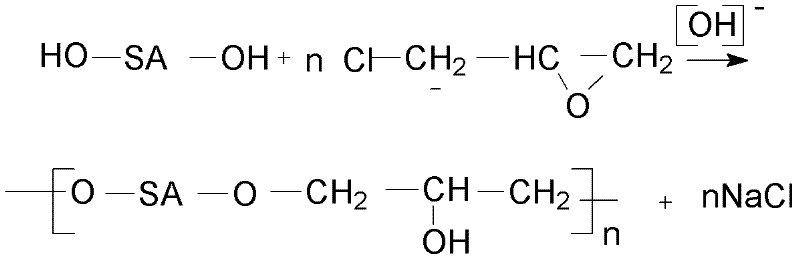

Method used

Image

Examples

Embodiment

[0022] In the experiment, we changed the reaction temperature, the dosage of cross-linking agent epichlorohydrin, the reaction time, and the pH value, and designed an orthogonal experiment. The results are shown in Table 1.

[0023] Table 1 L of sodium alginate modification condition 9 (3 4 ) Orthogonal experimental results

[0024]

[0025] Table 1 shows that the reaction time has the greatest impact on modified sodium alginate; the optimal reaction time between epichlorohydrin and sodium alginate is 1.5h. During the reaction process, the epoxy compound reacts with water at the same time, and there is a competing reaction between the crosslinking reaction and the hydrolysis of the epoxy compound. With the prolongation of the reaction time, the hydrolysis reaction intensifies, resulting in a decrease in the viscosity of the crosslinked alginic acid paste.

[0026] Sodium alginate solution is easily converted into alginic acid in acidic solution at pH, forming a gel to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com