Optical lens with free-form surfaces for LED automobile headlight

An optical lens, high beam technology, applied in optics, condenser mirrors, headlights, etc., can solve the problems of compressed optical system volume, complex optical system, difficult to control glare effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation of the present invention will not be described below in conjunction with the accompanying drawings and Examples, but the implementation and protection of the present invention are not limited thereto.

[0049] 1. Set the initial conditions and evenly divide the solid angle of the light source

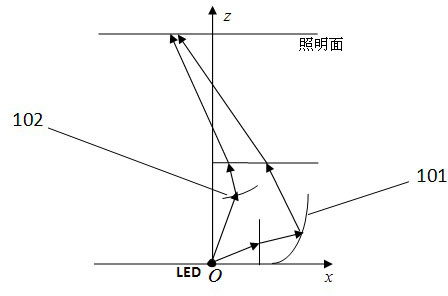

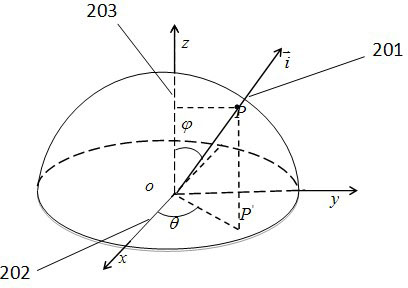

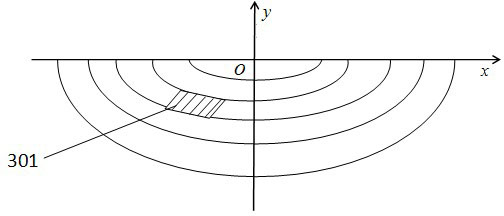

[0050] First, the distance between the target lighting surface and the LED is 25m. For the high beam, the target lighting area is set to be a partial ellipse with a major semi-axis of 4m and a minor semi-axis of 3m. For example image 3 As shown, it is a division diagram of an elliptical ring in the high beam target area, where 301 is a semi-elliptical ring area below the horizontal line, and a large number of ring areas together form a high beam lighting area. The total luminous flux of the LED light source is 300lm, and the light intensity of the LED center is 95.4930cd. figure 2 Shown is the spherical coordinate diagram of the LED light source in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com