Stamping single-station production simulating and verifying method

A simulation verification, single-station technology, applied in the direction of simulators, instruments, control/regulation systems, etc., can solve problems such as inconsistent effects, equipment damage, changes, poor programming quality and safety, to maximize efficiency and reduce revisions , The effect of optimizing the station layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

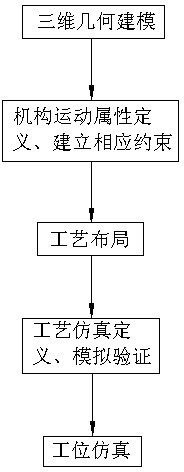

[0021] Such as figure 1 As shown, the stamping single station production simulation verification method of the present invention comprises the following steps:

[0022] A. Three-dimensional geometric modeling of end picker, auxiliary workbench, robot and press:

[0023] According to the environment of single-station verification, design and draw the 3D model of the upstream transmission platform, grabbing end picker assembly and press working environment, and confirm the corresponding tooling, stamping parts, environmental layout, robot and press model (basically composed of Provided by the manufacturer) data are available;

[0024] B. Definition of mechanism motion attributes and establishment of corresponding constraints:

[0025] In the mechanism definition module device building of the digital factory software, according to the actual mechanism characteristics and manufacturability, define the motion attributes of each part of the mechanism, such as interference, beat, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com