Method for processing freeze-dried fruit and vegetable products

A processing method and product technology, which is applied in the field of processing high-quality dehydrated food, can solve the problems of high production cost and restrict the development of freeze-dried food, and achieve the effect of low production cost, low operating cost and promotion of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Freeze-dried lychee processing process

[0034] (1) Selection of raw materials The raw materials are required to be fresh, free from disease, damage, and normal in color.

[0035] (2) Screening According to the raw material acceptance method, the qualified raw materials are screened out, and the inclusions are removed.

[0036] (3) Rinse the fruit with flowing water for washing and sterilization to remove the surface sediment. Use ozone to sterilize, ozone concentration 2mg / m 2 , Hold for 2 minutes.

[0037] (4) Dehulling and denucleating are removed with a special dehulling and denucleating machine.

[0038] (5) Cut into 4 pieces with a cutting machine.

[0039] (6) Ozone is used for sterilization, and the concentration of ozone is 3mg / m 2 , Hold for 2 minutes.

[0040] (7) Spreading trays Evenly spread the cut petals into the freeze-drying trays, with a loading capacity of 8-9kg / m 2 , the best loading capacity is 8.5kg / m 2 .

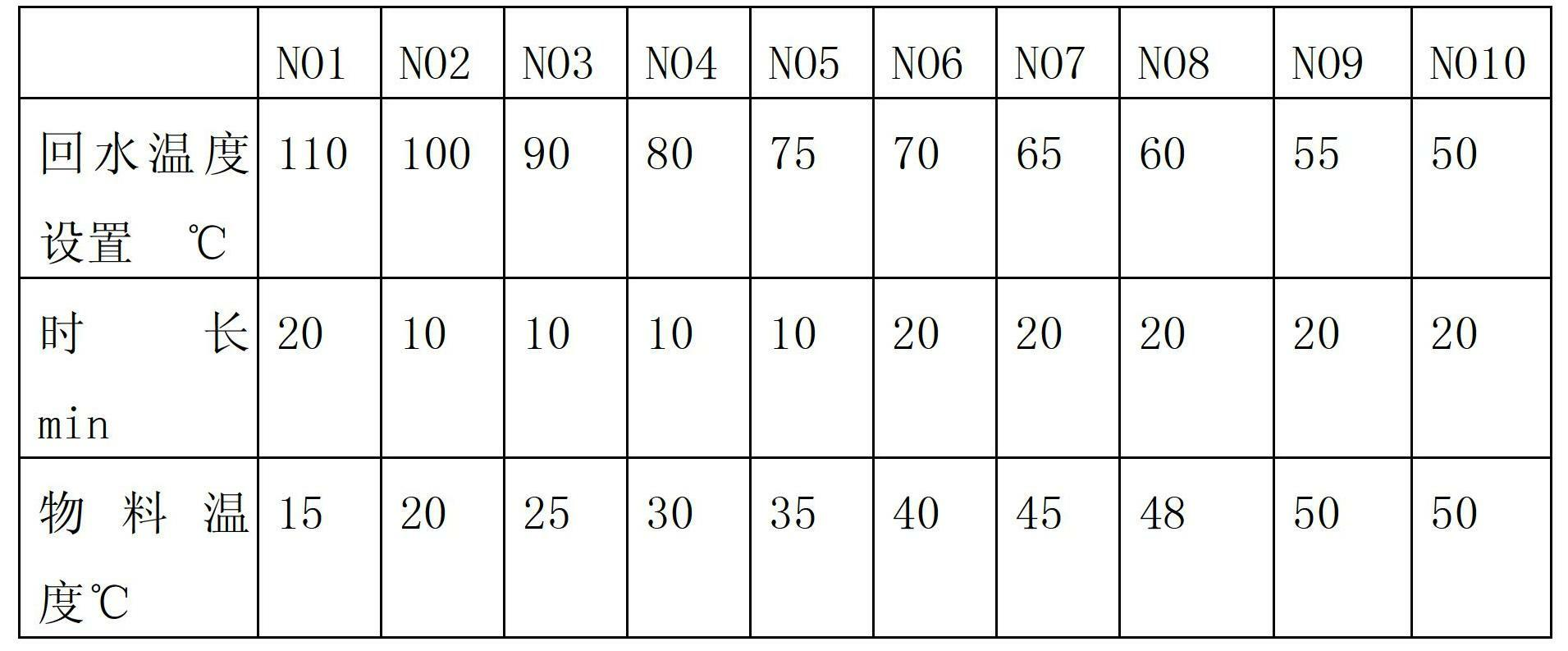

[0041] (8) Pre-freezing Pre-free...

Embodiment 2

[0050] Freeze-dried apple processing process

[0051] (1) Selection of raw materials The raw materials are required to be fresh, without damage, stored for ≤3 months after the harvest season, and the internal tissue color is uniform without discoloration.

[0052] (2) Screening According to the raw material acceptance method, the qualified raw materials are screened out, and inclusions are removed.

[0053](3) Rinse the fruit with flowing water for washing and sterilization to remove the surface sediment. Use ozone to sterilize, ozone concentration 2mg / m 2 , Hold for 2 minutes.

[0054] (4) Peeling and pitting are removed with a special peeling machine and pitting machine.

[0055] (5) Cut into 8 pieces with a cutting machine.

[0056] (6) Use 0.5% VC for color protection and sterilization. Use ozone to sterilize, ozone concentration 3mg / m 2 , Hold for 2 minutes.

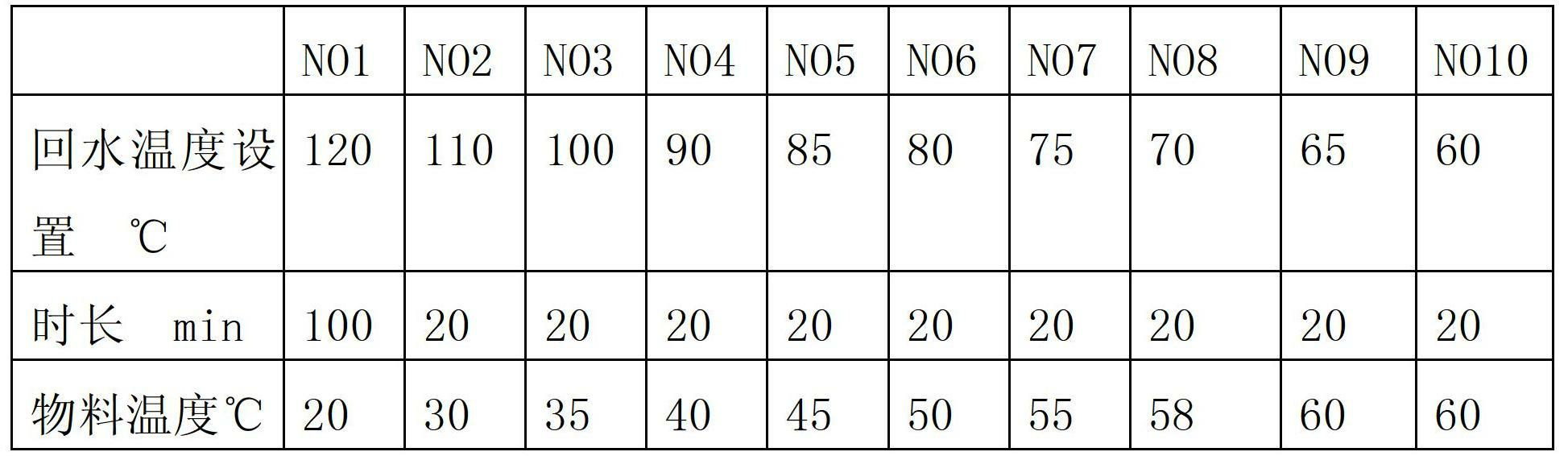

[0057] (7) Spreading trays Spread the cut petals evenly into the freeze-drying trays, with a loading capac...

Embodiment 3

[0064] Freeze-dried apricot processing process

[0065] (1) Selection of raw materials, raw materials require a maturity of more than 80%, no bruises and deterioration, and uniform internal tissue color without discoloration.

[0066] (2) Screening: Screen out qualified raw materials according to the raw material acceptance method, and pay attention to removing inclusions.

[0067] (3) Wash fruit, sterilize, rinse with running water, and wash away surface sediment. Use ozone to sterilize, ozone concentration 2mg / m 2 , Hold for 2 minutes.

[0068] (4) De-nucleation is removed with a special de-nucleation machine.

[0069] (5) Cut into 4 pieces with a cutting machine.

[0070] (6) Use 0.5% VC for color protection and sterilization. Use ozone to sterilize, ozone concentration 3mg / m 2 , Hold for 2 minutes.

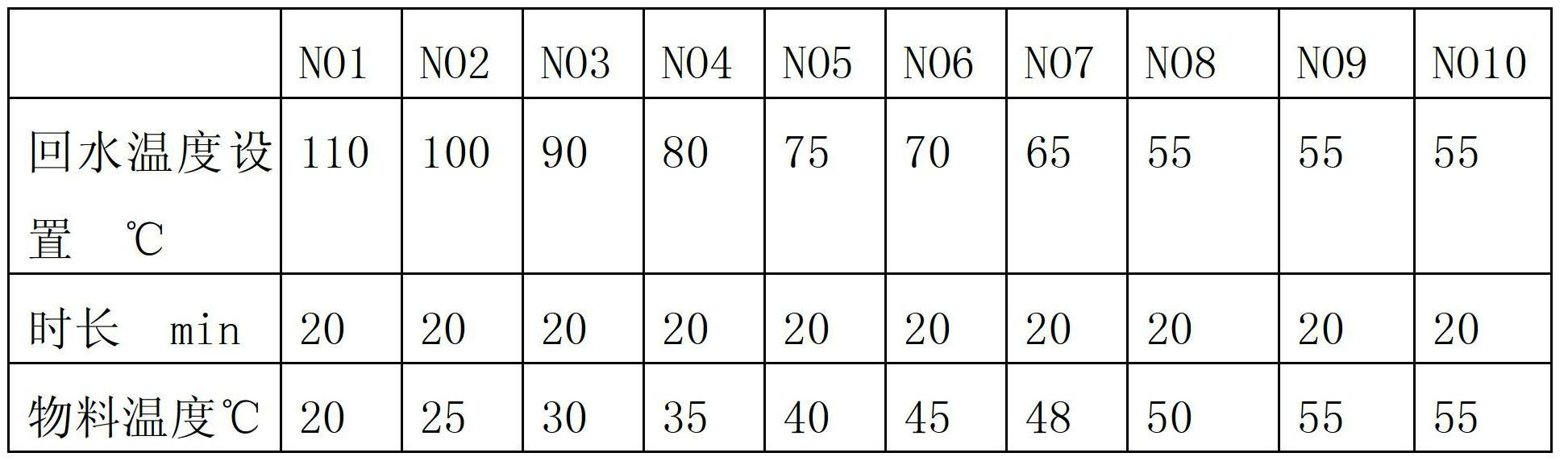

[0071] (7) Spreading trays Evenly spread the cut petals into the freeze-drying trays, with a loading capacity of 8-9kg / m 2 , the best loading capacity is 8.5kg / m 2 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com