Method for preparing dispersing-stabilizing agent by using papermaking sludge

A technology of papermaking sludge and stabilizer, which is applied in the chemical field to achieve the effects of improving utilization rate, mild reaction conditions and reducing discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1. Method of the invention - two-step sulfonation of lignin and carboxymethylation of cellulose

[0031] Take 10g of papermaking sludge, add 100ml of deionized water, add dropwise 10% NaOH solution while stirring, control the pH value at about 11.5, about half an hour, and pour it into the reactor after the pH=11.5 remains unchanged. Heat the reactor water bath to 90°C, add 2.5g of anhydrous sodium sulfite, stir, react for 2h, adjust the temperature to 60°C, slowly add 1.0ml of 30% hydrogen peroxide solution dropwise, stir, and react for 20min. Adjust the temperature back to 90°C, add a condenser, add 5.5ml of 37% formaldehyde solution dropwise, stir, react for 1h, then add 3.0g of anhydrous sodium sulfite, react for 3h, lower the temperature to 35°C, add 2.3g of monochloroacetic acid, After stirring for 2.5 hours, the product was dried at 70°C and crushed. A dispersant-stabilizer containing sodium lignosulfonate-sodium carboxymethylcellulose, code-named SL 2 ...

Embodiment 2

[0032] Embodiment 2. One-step sulfonation of lignin in raw materials:

[0033] Take 10g of papermaking sludge, add 100ml of deionized water, add dropwise 10% NaOH solution while stirring, control the pH value at about 11.5, about half an hour, and pour it into the reactor after the pH=11.5 remains unchanged. Heat the reactor water bath to 90°C, add 2.5g of anhydrous sodium sulfite, stir, react for 2h, dry the product at 70°C, and pulverize. The one-step sulfonation product of lignin in this example is used as a comparative example, code-named SL 1 .

Embodiment 3

[0034] Example 3. Two-step sulfonation of lignin in raw materials:

[0035] Take 10g of papermaking sludge, add 100ml of deionized water, add dropwise 10% NaOH solution while stirring, control the pH value at about 11.5, about half an hour, and pour it into the reactor after the pH=11.5 remains unchanged. Heat the reactor water bath to 90°C, add 2.5g of anhydrous sodium sulfite, stir, react for 2h, adjust the temperature to 60°C, slowly add 1.0ml of 30% hydrogen peroxide solution dropwise, stir, and react for 20min. Adjust the temperature back to 90°C, add a condenser, add 5.5ml of 37% formaldehyde solution dropwise, stir, react for 1h, then add 3.0g of anhydrous sodium sulfite, react for 3h to obtain the product, dry at 70°C, and pulverize. The two-step sulfonation product of lignin in this example is used as a comparative example, code-named SL 2 .

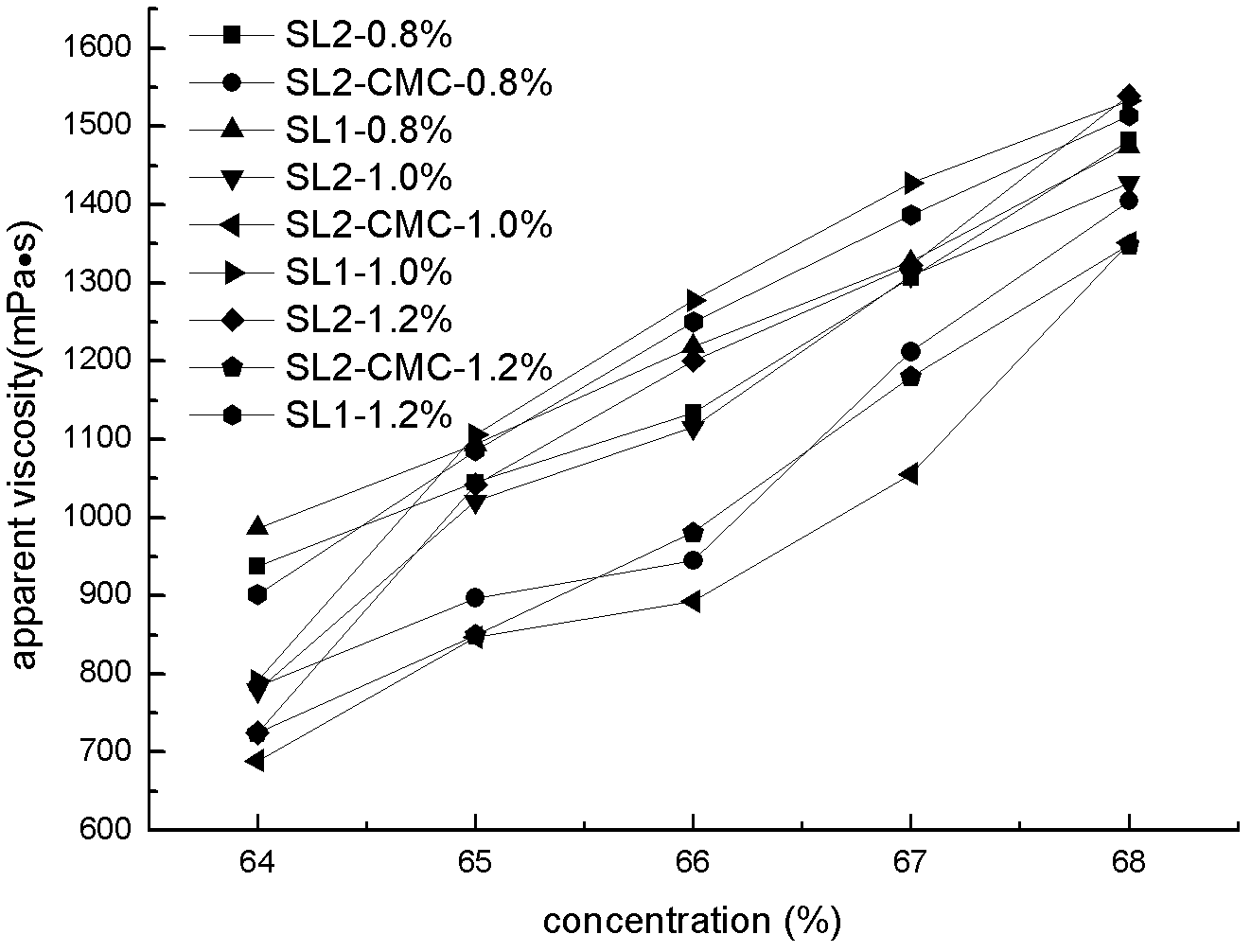

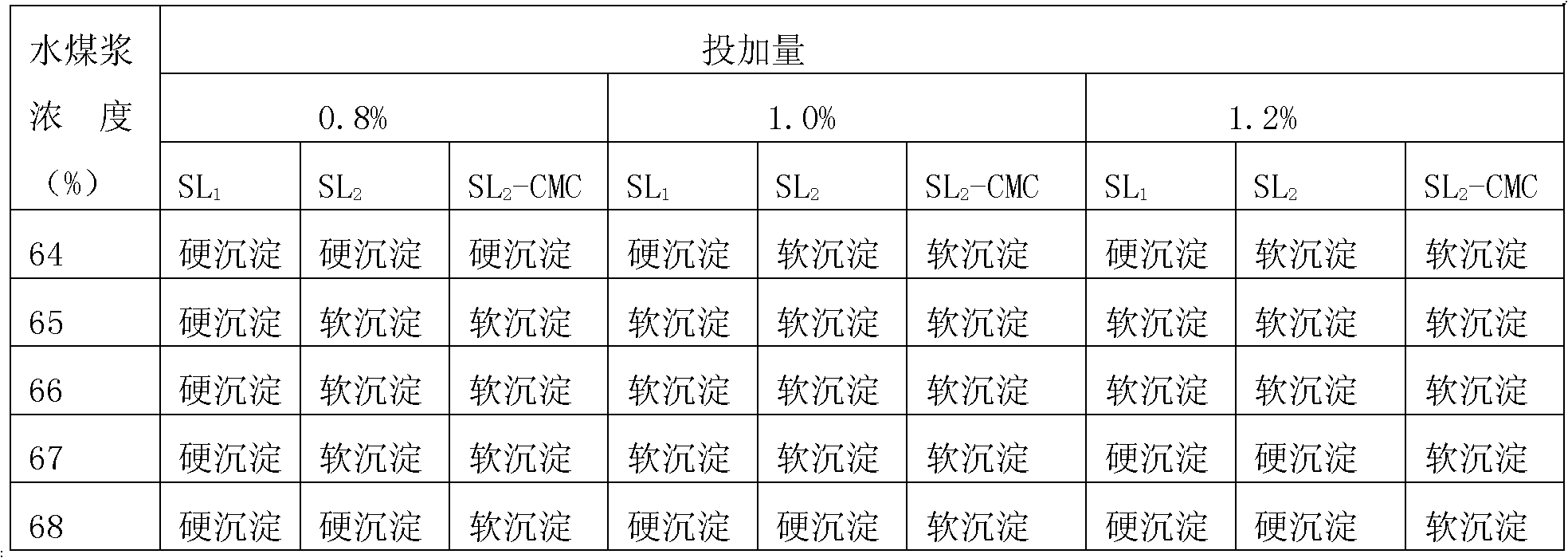

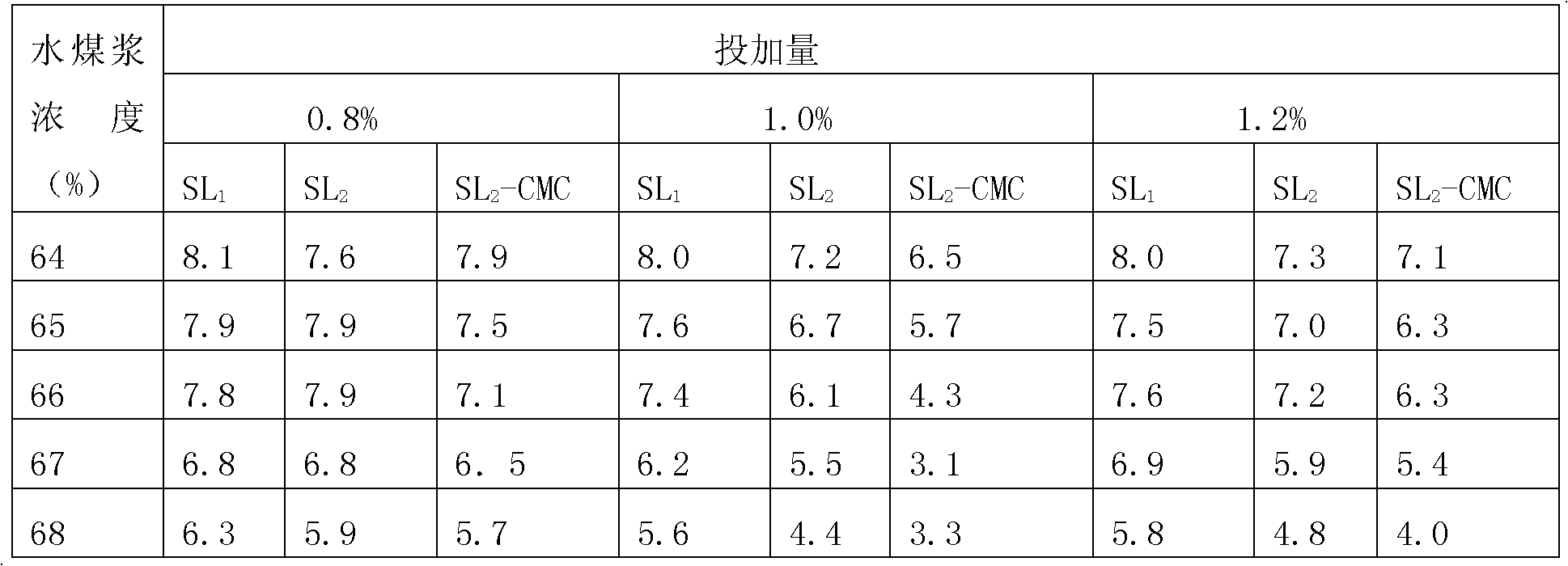

[0036] The product of embodiment 1-3 is joined in the coal-water slurry and carries out stability, water analysis property, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com