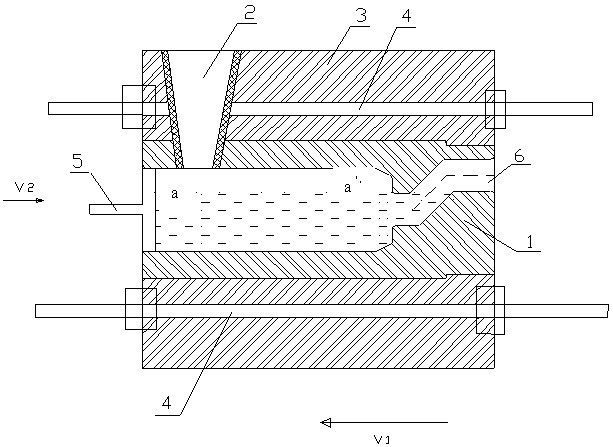

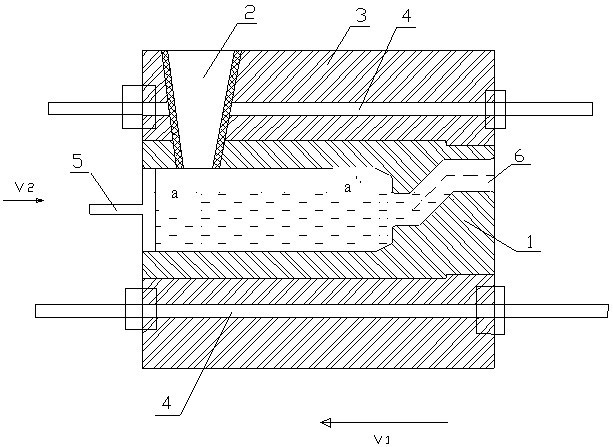

Method and die for thinning microstructure of magnesium alloy material through continuous chill casting, squeezing and cutting

A technology of alloy material and microstructure, which is applied in the field of continuous chilled casting, extrusion and shearing to refine the microstructure of magnesium alloy materials, can solve the problems that the effect of grain refinement needs to be improved and is not obvious, and achieves shortened production cycle and wide range of materials , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in combination with specific embodiments.

[0027] The method for continuous quenching casting, extrusion and shearing of the present invention to refine the microstructure of magnesium alloy materials is characterized in that it comprises the following steps:

[0028] 1. Inject the high-temperature or semi-solid magnesium alloy melt and the magnesium alloy composite modifier from the sprue cup into the inner cavity of the casting extrusion mold; the magnesium alloy composite modifier can be selected from a suitable formula in the prior art; a specific magnesium alloy composite modifier, which includes C 2 Cl 6 , Zr, CaCO 3 Three components, the mass ratio range of the three components is 1.5-2.5:0.8-1.8:0.7-1.6, and the quality of the modifier added is 0.1-0.12% of the mass of the high-temperature magnesium alloy melt; The best range of mass ratio is 2:1:1;

[0029] 2. A cooling water jacket is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com