Low-temperature mechanical alloying method for preparing sulphur selenide submicro powder material

A technology of mechanical alloying and sulfur selenide, applied in the field of material chemistry, can solve the problems of unsuitable industrial scale production, low product yield, easy introduction of impurities, etc., to avoid high temperature agglomeration and growth, easy operation, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

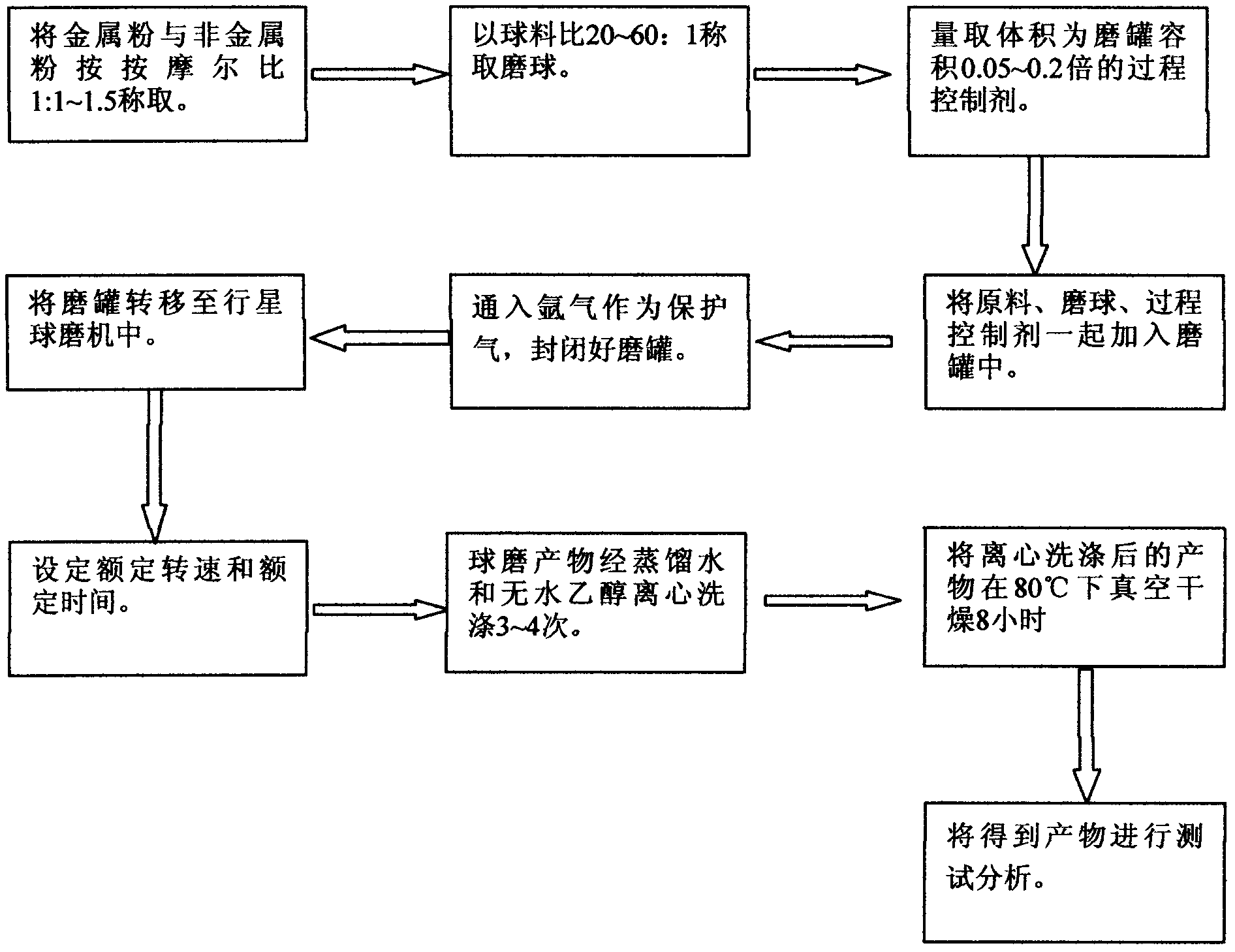

Method used

Image

Examples

Embodiment 1

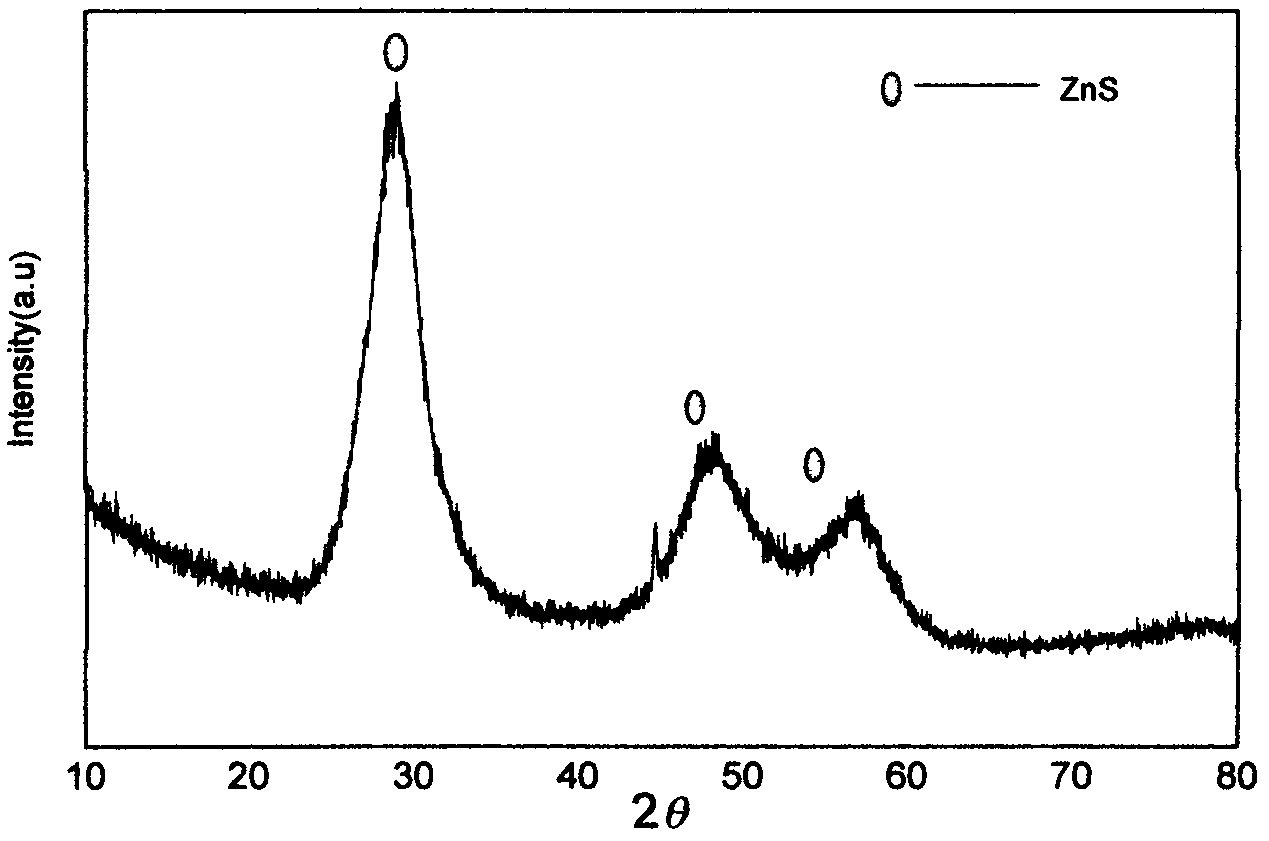

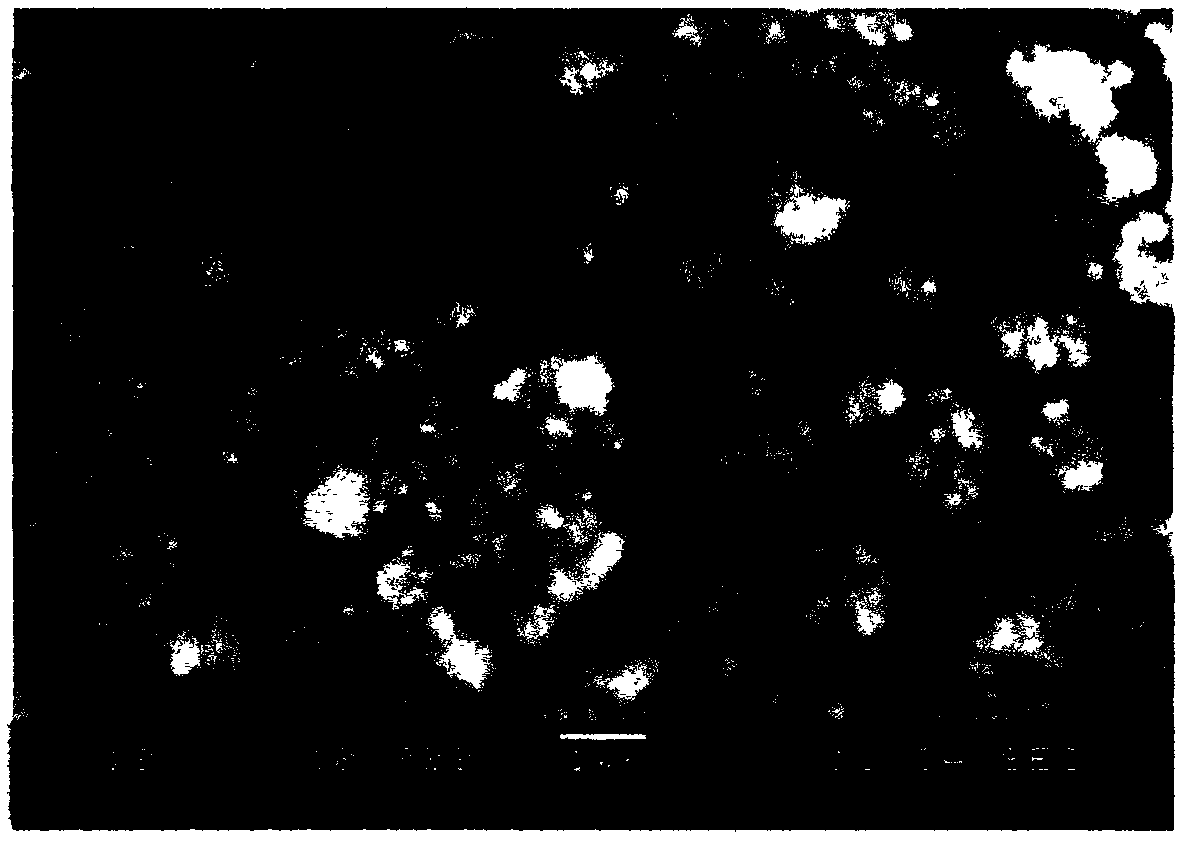

[0025] Embodiment 1: (ZnS powder)

[0026] (1) With elemental Zn powder and elemental S powder as raw materials, weigh 6.53 grams of Zn powder and 3.2 grams of S powder in a molar ratio of 1:1, and weigh 583 grams according to the mass ratio of the grinding ball to the weighed raw material of 60:1. Gram balls, measure 25mL process control agent (20mL absolute ethanol + 5mL analytically pure ethylenediamine) with a graduated cylinder;

[0027] (2) Add the raw materials weighed in step (1), balls and process control agent together into a grinding tank with a volume of 500mL, feed argon as a protective gas, seal the grinding tank, and transfer the grinding tank to a planetary ball mill, The set speed is 600 rpm, and the ball milling time is 72 hours;

[0028] (3) The product obtained in step (2) was centrifugally washed 3 times with distilled water and absolute ethanol, and the product after centrifugal washing was vacuum-dried at 80° C. for 8 hours in a vacuum oven to obtain th...

Embodiment 2

[0029] Embodiment 2: (ZnSe powder)

[0030] (1) With elemental Zn powder and elemental Se powder as raw materials, weigh 6.53 grams of Zn powder and 11.84 grams of Se powder in a molar ratio of 1:1.5, and weigh 367 grams according to the mass ratio of the grinding ball to the weighed raw material of 20:1. Gram balls, measure 100mL process control agent (75mL absolute ethanol + 25mL analytically pure ethylenediamine) with a graduated cylinder;

[0031] (2) Add the raw materials weighed in step (1), balls and process control agent together into a grinding tank with a volume of 500mL, feed argon as a protective gas, seal the grinding tank, and transfer the grinding tank to a planetary ball mill, The set speed is 600 rpm, and the ball milling time is 5 hours;

[0032] (3) The product obtained in step (2) was centrifuged and washed 3 times with distilled water and absolute ethanol, and the product after centrifugal washing was vacuum-dried at 80° C. for 8 hours in a vacuum drying ...

Embodiment 3

[0033] Embodiment 3: (SnS powder)

[0034] (1) Using elemental Sn powder and elemental S powder as raw materials, weigh 11.87 grams of Sn powder and 3.84 grams of S powder in a molar ratio of 1:1.2, and weigh 628 grams according to the mass ratio of the grinding ball to the weighed raw material of 40:1. Grind the ball, and use a graduated cylinder to measure 100mL of process control agent (75mL of absolute ethanol + 25mL of analytically pure ethylenediamine).

[0035] (2) Add the raw materials weighed in step (1), balls and process control agent together into a grinding tank with a volume of 500mL, feed argon as a protective gas, seal the grinding tank, and transfer the grinding tank to a planetary ball mill, The set speed is 400 rpm, and the ball milling time is 12 hours;

[0036] (3) The product obtained in step (2) was centrifuged and washed 3 times with distilled water and absolute ethanol, and the product after centrifugal washing was vacuum-dried in a vacuum oven at 80°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com