Purification method of hyodeoxycholic acid

A technology of hyodeoxycholic acid and its purification method, which is applied in the field of biochemical pharmacy, can solve the problems of ethyl acetate consumption, low product purity, and large reagent usage, and achieve the effect of simple operation method and overcoming low product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

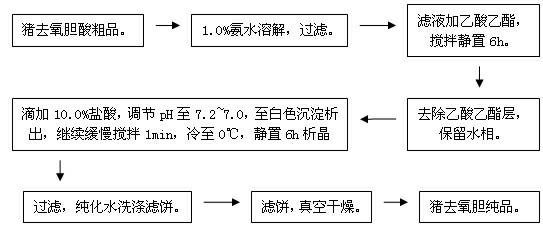

Method used

Image

Examples

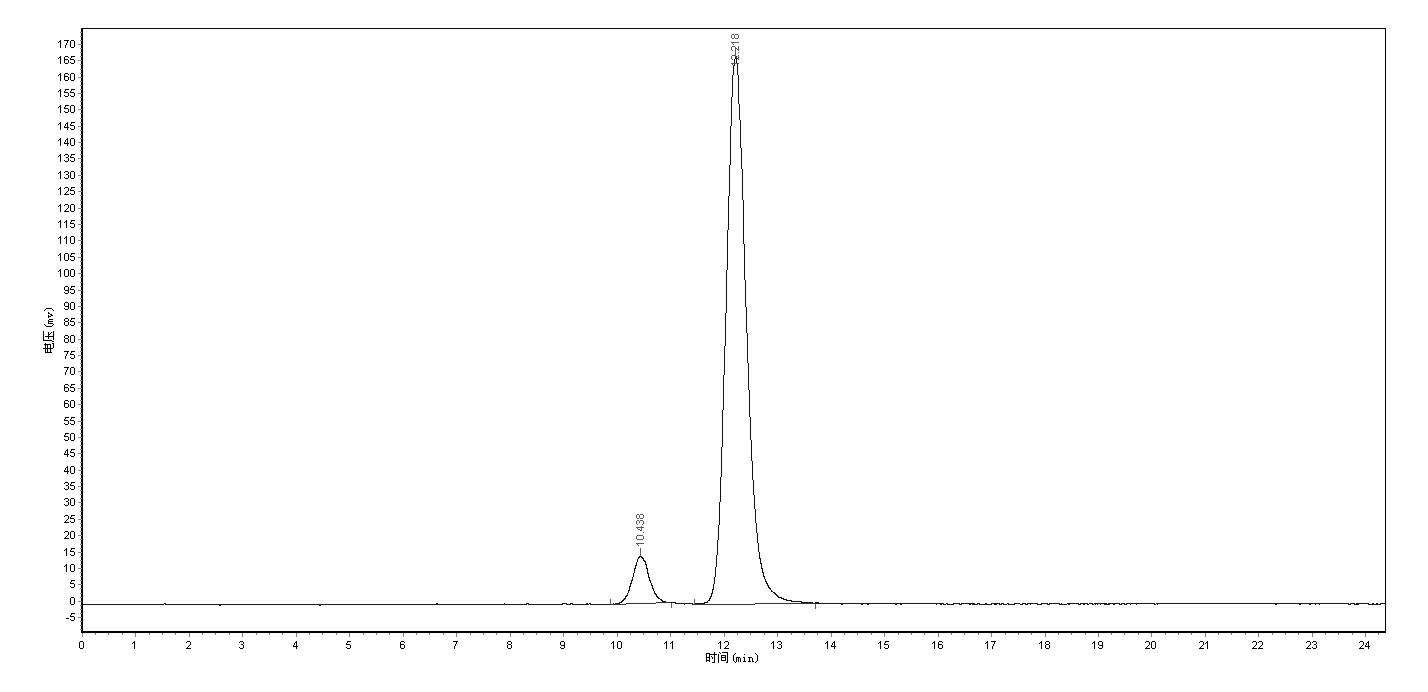

Embodiment 1

[0021] Take 10g of crude hyodeoxycholic acid and add it to a beaker, then add 3000ml of ammonia water with a mass concentration of 1.0%, the content of hyodeoxycholic acid in the solution is 3.3%, keep the temperature to room temperature, stir for 5min, filter to remove insoluble impurities, collect the filtrate, and the yield More than 99%; add 500ml ethyl acetate to the collected filtrate, stir thoroughly for 5 minutes, let it stand for 6 hours, remove ethyl acetate by siphon, and obtain the aqueous phase liquid, the yield is 97%; put the aqueous phase liquid in a beaker, slowly drop Add hydrochloric acid solution with a mass concentration of 10.0%, adjust the pH value to 7.2 with a pH meter, continue to stir slowly for 1 min, cool to 0°C, let stand for 6 h to crystallize, filter, wash the filter cake with 1000 ml of purified water, and dry under reduced pressure 9.1 g of white crystalline hyodeoxycholic acid was obtained, with a yield of 90%. The melting point is above 197....

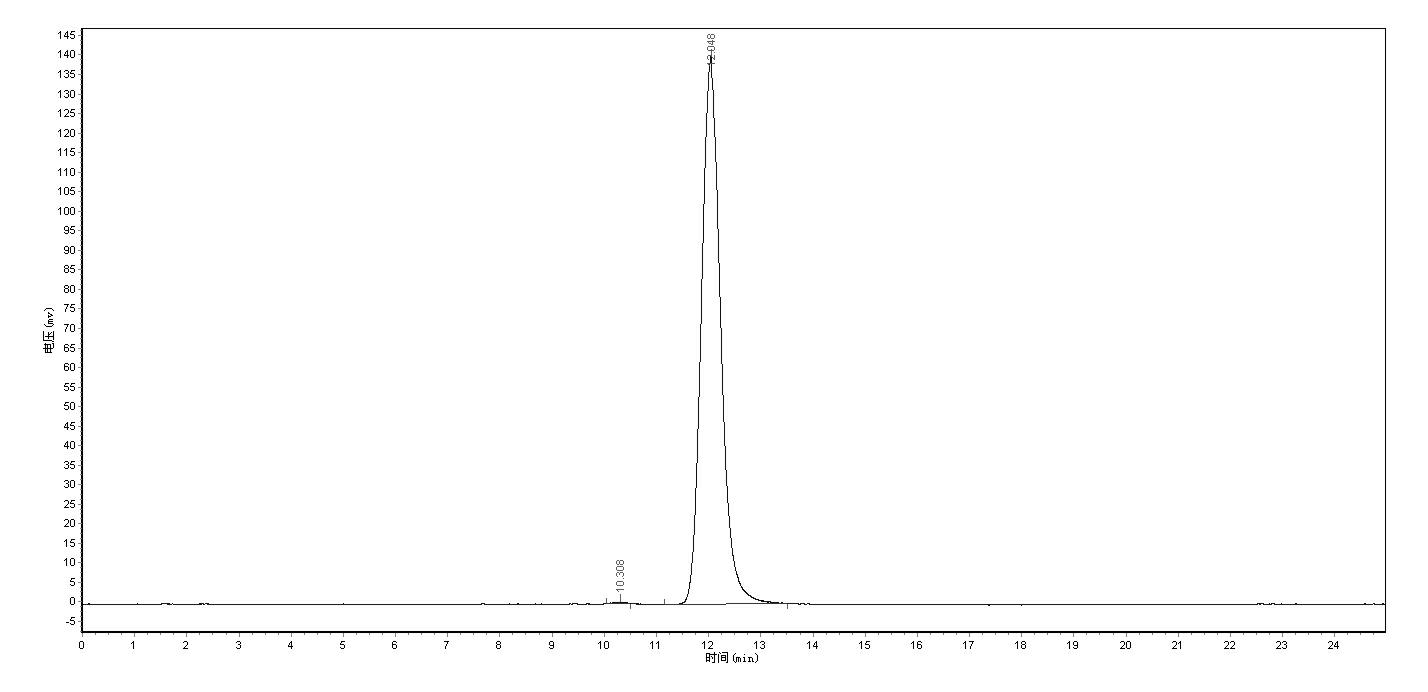

Embodiment 2

[0023] Take 10g of crude hyodeoxycholic acid and add it to a beaker, then add 2750ml of ammonia water with a mass concentration of 1.0%, the content of hyodeoxycholic acid in the solution is 3.6%, keep the temperature to room temperature, stir for 5min, filter to remove insoluble impurities, collect the filtrate, and the yield More than 98%; add 450ml ethyl acetate to the collected filtrate, stir thoroughly for 5 minutes, let it stand for 6 hours, remove ethyl acetate by siphon, and obtain the aqueous phase liquid, the yield is 96%; put the aqueous phase liquid in a beaker, slowly drop Add hydrochloric acid solution with a mass concentration of 10.0%, adjust the pH value to 7.1 with a pH meter, continue to stir slowly for 1 min, cool to 0°C, let stand for 6 h to crystallize, filter, wash the filter cake with 900 ml of purified water, and dry under reduced pressure 8.8 g of white crystalline hyodeoxycholic acid was obtained, with a yield of 89%. The melting point is above 197.5...

Embodiment 3

[0025] Take 10g of crude hyodeoxycholic acid and add it to a beaker, then add 2500ml of ammonia water with a mass concentration of 1.0%, the content of hyodeoxycholic acid in the solution is 4.0%, keep the temperature to room temperature, stir for 5min, filter to remove insoluble impurities, collect the filtrate, and the yield More than 97%; add 600ml ethyl acetate to the collected filtrate, stir thoroughly for 5 minutes, let it stand for 6 hours, remove ethyl acetate by siphon, and obtain the aqueous phase liquid, the yield is 98%; put the aqueous phase liquid in a beaker, slowly drop Add a hydrochloric acid solution with a mass concentration of 10.0%, adjust the pH value to 7.0 with a pH meter, continue stirring slowly for 1 min, cool to 0°C, let stand for 6 h to crystallize, filter, wash the filter cake with 800 ml of purified water, and dry under reduced pressure 9.0 g of white crystalline hyodeoxycholic acid was obtained, with a yield of 91%. The melting point is above 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com