Preparation method of heparin lithium

A technology of lithium heparin and heparinase, which is applied in the field of lithium heparin preparation, can solve the problems of large investment in hardware facilities, high cost of raw materials, and large investment in hardware for the production of lithium heparin, and meets the requirements of mild dynamic ion exchange process and ambient temperature of resin method The effect of low investment and small investment in hardware facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

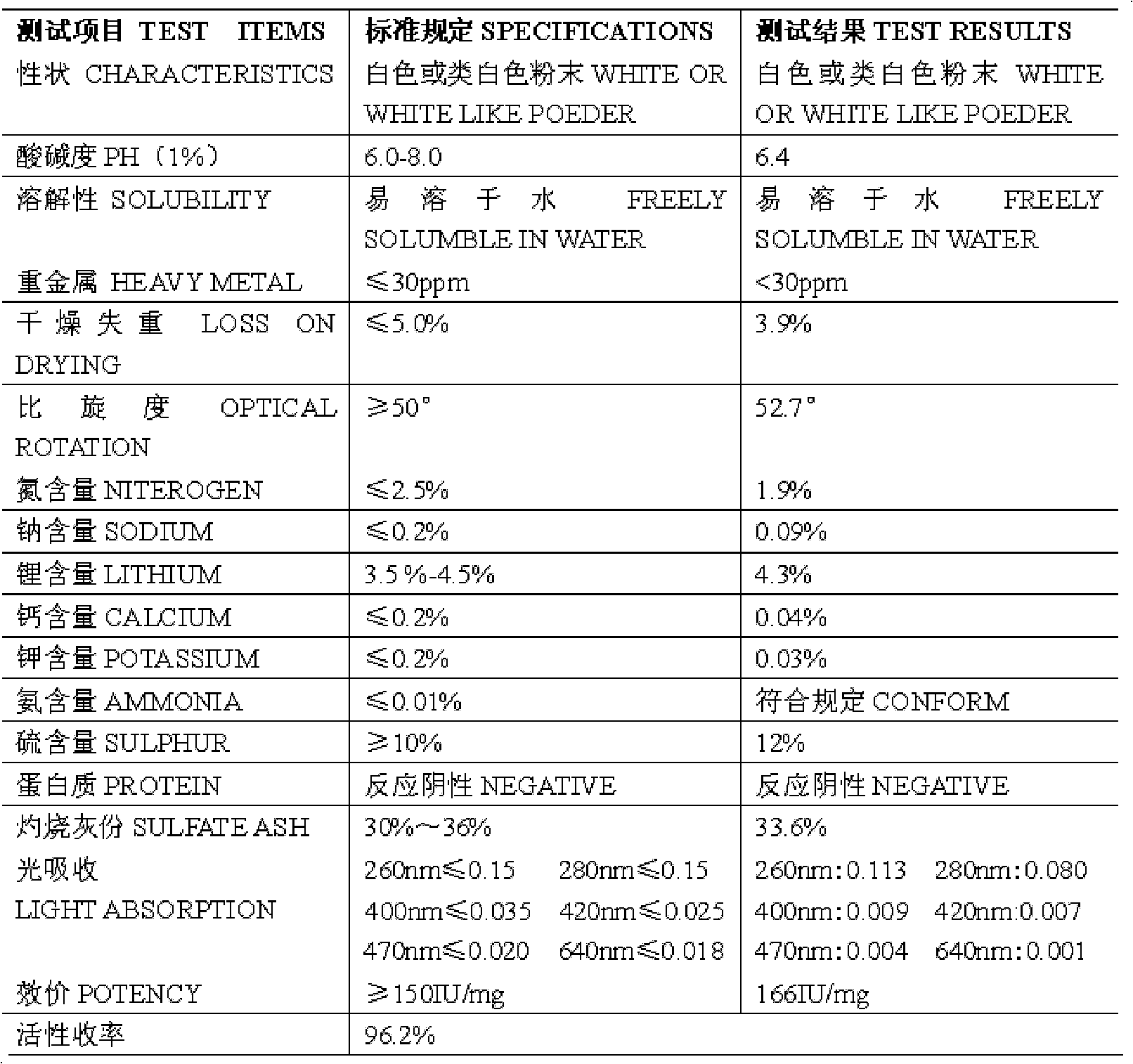

Examples

Embodiment 1

[0020] Step 1: Stir and dissolve the crude sodium heparin raw material (commercially available raw material, potency 65-105IU / mg) with 1%-3% NaCl solution, the concentration of crude sodium heparin is 8%-16% (mass percentage concentration ), adjust the pH to 7.5-9.0 with 5M NaOH solution, heat up to 50-55°C, add heparin enzymolysis trypsin according to 0.1-0.3% of the mass of the crude product heparin sodium solution, keep warm for 4-5 hours, and use 5M NaOH Adjust the pH value of the solution to 9.0-11, heat up to 85°C-90°C, cool to room temperature, filter to remove the precipitate, and precipitate the filtrate with 0.8-1.5 times the volume of 95% ethanol for more than 4 hours, and collect the precipitate A;

[0021] Step 2: Stir and dissolve the precipitate A with pure water, the dissolved concentration is 10%-20% (mass percentage), adjust the pH to 8.5-11 with 5M NaOH solution, and press 0.1%-5% of the mass of the precipitate A aqueous solution Add protein flocculation and...

Embodiment 2

[0026] The heparin enzymolysis trypsin in step 1 is selected as compound trypsin containing trypsin;

[0027] The protein flocculation precipitant in step 2 is selected polyaluminum chloride for use;

[0028] The other steps were the same as in Example 1 to obtain the lithium heparin fine product.

Embodiment 3

[0030] The heparin enzymolysis trypsin in step 1 is selected as neutral trypsin;

[0031] The protein flocculation precipitant in step 2 is selected sodium polyacrylate for use;

[0032] The other steps were the same as in Example 1 to obtain the lithium heparin fine product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com