Feed with enzymatic small peptide-additive complex and preparation methods thereof

A technology of additives and complexes, applied in the field of feed with enzymatically hydrolyzed small peptide-additive complexes and its preparation, can solve the problems of poor absorption, waste, and low biological potency of feed additives, and increase the content of small peptides , Improve utilization efficiency, improve the effect of hydrolysis degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

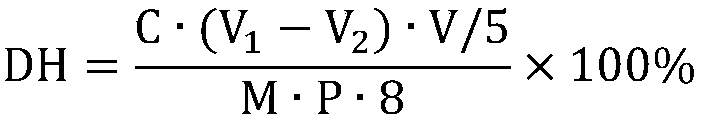

Method used

Image

Examples

Embodiment 1

[0049] Add 650kg of soybean protein, 250kg of lard, and 150kg of soybean oil to 2000kg of water, then add 4kg of emulsifier, control the temperature between 50-60°C, stir, homogenize and refine through a homogenizer, and the pressure is about 25-35MPa, and then Enter the emulsification machine for processing. The rotor speed of the emulsification machine is about 1500r / min. In the reasonably narrow gap between the static grinding plate, the moving grinding plate and the propeller blade, strong and reciprocating hydraulic shearing, friction and centrifugal force are formed. After the combined effect of extrusion, liquid flow collision, etc., it lasted about 120 minutes, and then the material was injected into the enzymatic hydrolysis tank, the pH value was about 7.0, and 1.2kg of neutral protease, 1.2kg of papain, and 1.2kg of lipase were added, and the temperature was controlled. Between 45-60°C, stir at a constant speed for 90 minutes, then add to another reaction tank, add ab...

Embodiment 2

[0051] Put 250kg of soybean oil, 250kg of palm oil, 450kg of soybean meal, and 150kg of plasma protein powder into 2000kg of aqueous solution, then add 8kg of emulsifier, control the temperature at about 30-65°C, stir, and then enter the emulsifier for processing, and the rotor of the emulsifier The rotation speed is about 16000r / min. After the combined effects of strong and reciprocating hydraulic shearing, friction, centrifugal extrusion, and liquid flow collision are formed in the reasonably narrow gap between the stator and the rotor, it takes about 50 minutes. Add the material to the enzymatic hydrolysis tank, add 1.5kg of Bacillus subtilis, 1.5kg of papain, and 1.0kg of bromelain, control the temperature at 60°C, and the pH value is about 7.0, stir at a constant speed for 90 minutes, and then add it to another reaction tank. Add 0.5kg of ferrous sulfate and 0.1kg of vitamin C, stir for 30 minutes, and then dry the semi-finished material to become a powder. The dried produ...

Embodiment 3

[0053] Put 220kg of palm oil, 220kg of soybean oil, 450kg of soybean meal, and 200kg of fish meal into 2000kg of aqueous solution, then add 18kg of emulsifier, control the temperature at about 45-56°C, stir, and enter the high-pressure homogenizer for homogenization, the pressure can be 380MPa The internal adjustment is free, and the material is circulated in the container through the circulation pipe to achieve the purpose of refinement, and then enters the emulsification machine for processing. The rotor speed of the emulsification machine is 2800r / min. After forming strong, reciprocating hydraulic shearing, friction, centrifugal extrusion, liquid flow collision and other comprehensive effects in the reasonably narrow gap between them, it lasted about 70 minutes, and then the materials were added to the enzymatic hydrolysis tank with a pH value of 5.5 -7.5, add bromelain 3.5kg, cellulase 1.0kg, temperature control between 40-60 ℃, enzymatic hydrolysis for 160 minutes, then po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com