Method for refining capsanthin by enzyme catalysis, esterification and molecular distillation

A technology of capsanthin and molecular distillation, which is applied in the field of natural organic chemistry, can solve the problems of by-products that cannot be directly used, difficult degassing, high distillation temperature, etc., and achieves the effects of low production cost, simple process and high product content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

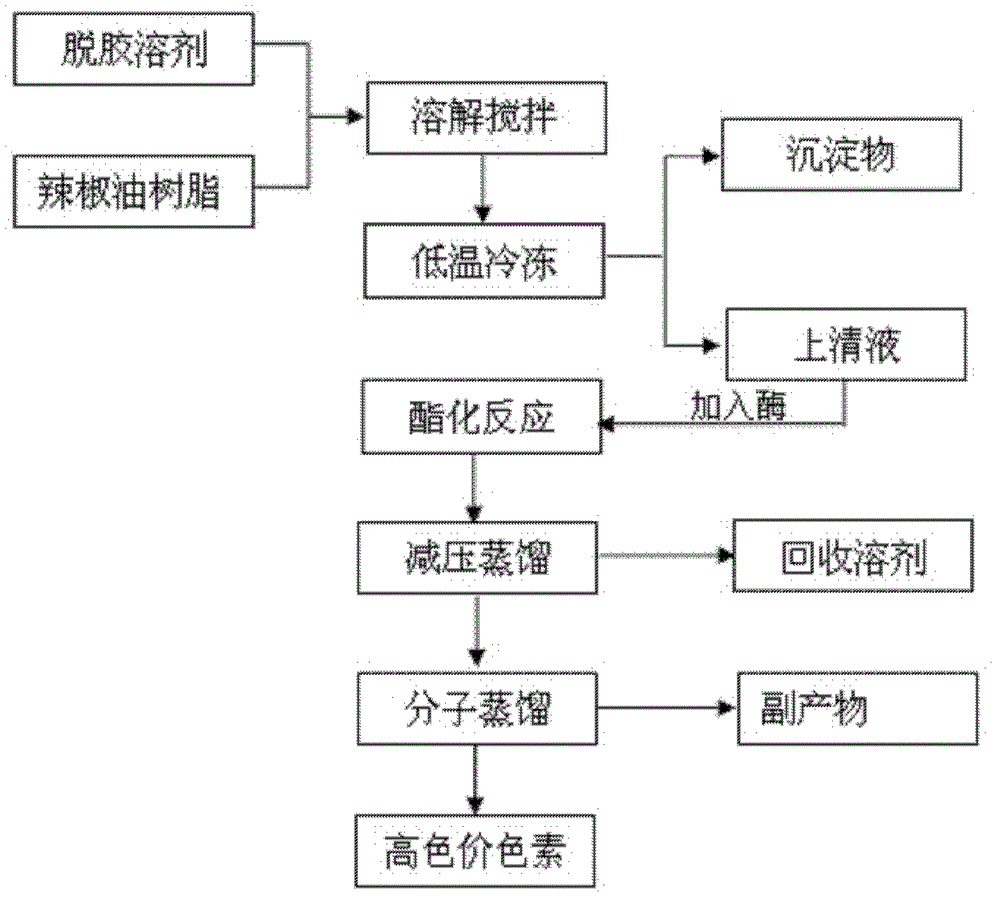

[0032] A method of enzymatic esterification molecular distillation refining capsanthin of the present invention (such as figure 1 shown), including the following steps:

[0033] Step 1: Degumming

[0034] (1) 10Kg capsanthin oleoresin and 10kg degumming agent (absolute ethanol) are packed in the jacketed reactor, at 60 ℃, stir with 100 rev / min speeds.

[0035] (2) After stirring evenly, pump the mixed solution into a freezing tank, control the temperature of the freezing tank at 5°C, and let it settle.

[0036] (3) After settling for 5 hours, the freezing liquid is 3×10 4 Under the condition of Pa, the upper part of the freezing tank is sucked into a vacuum filter to obtain a filtrate, and the filtrate is separated by a tubular centrifuge to obtain a degummed pigment solution.

[0037] Step 2: Esterification reaction

[0038] (1) Add the degummed pigment solution into the enzyme reactor, add 50g of lipase (Novozym 435) and 100g of water, mix well, control the reaction temp...

Embodiment 2

[0044] In this embodiment, a method for refining capsanthin by enzyme-catalyzed esterification molecular distillation, except for the following differences, other steps and process conditions thereof are the same as in Example 1:

[0045] (1) The quality of adding capsanthin oleoresin and methanol is 10Kg and 50Kg respectively, and stirs evenly at a speed of 500 rpm at 20°C.

[0046] (2) The temperature of the freezing tank is 3°C, and it is left to settle for 10 hours.

[0047] (3) The temperature of the esterification reaction is 45° C., and the reaction is carried out for 5 hours, and the stirring speed is 150 rpm.

[0048] (4) Dehydration under reduced pressure for 2 hours.

[0049] (5) The temperature of the solvent recovered under reduced pressure is 40°C, and the vacuum degree is 6×10 4 Pa.

[0050] (6) The mass ratio of degumming agent, lipase and water is 100:3:3.

[0051] (7) The lipase is Lipozyme RM IM.

[0052] (8) The primary degassing temperature is 100°C, ...

Embodiment 3

[0056] In this embodiment, a method for refining capsanthin by enzyme-catalyzed esterification molecular distillation, except for the following differences, other steps and process conditions thereof are the same as in Example 1:

[0057] (1) Adding capsanthin oleoresin and volume fraction of 95% ethanol aqueous solution are 10Kg and 100Kg respectively, and stirred evenly at 800 rpm at 35°C.

[0058](2) The temperature of the freezing tank is 0°C, and it is allowed to settle for 20 hours.

[0059] (3) The esterification reaction temperature is 30°C, and the reaction is carried out for 10 hours, and the stirring speed is 300 rpm.

[0060] (4) Dehydration under reduced pressure for 3 hours.

[0061] (5) The solvent recovery temperature under reduced pressure is 50°C, and the vacuum degree is 4×10 4 Pa.

[0062] (6) The mass ratio of degumming agent, lipase and water is 100:10:5.

[0063] (7) The lipase is Lipozyme RM IM.

[0064] (8) The primary degassing temperature is 50°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com