Green fluorescent material for alternating current - light-emitting diode (AC-LED) and preparation method thereof

A technology of green fluorescence and mixing materials, which is applied in the field of green fluorescent materials and their preparation, can solve the problems of reduced luminous efficiency, color change of emission spectrum, and reduced luminous intensity, so as to improve luminous intensity, reduce power consumption, and eliminate flickering problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

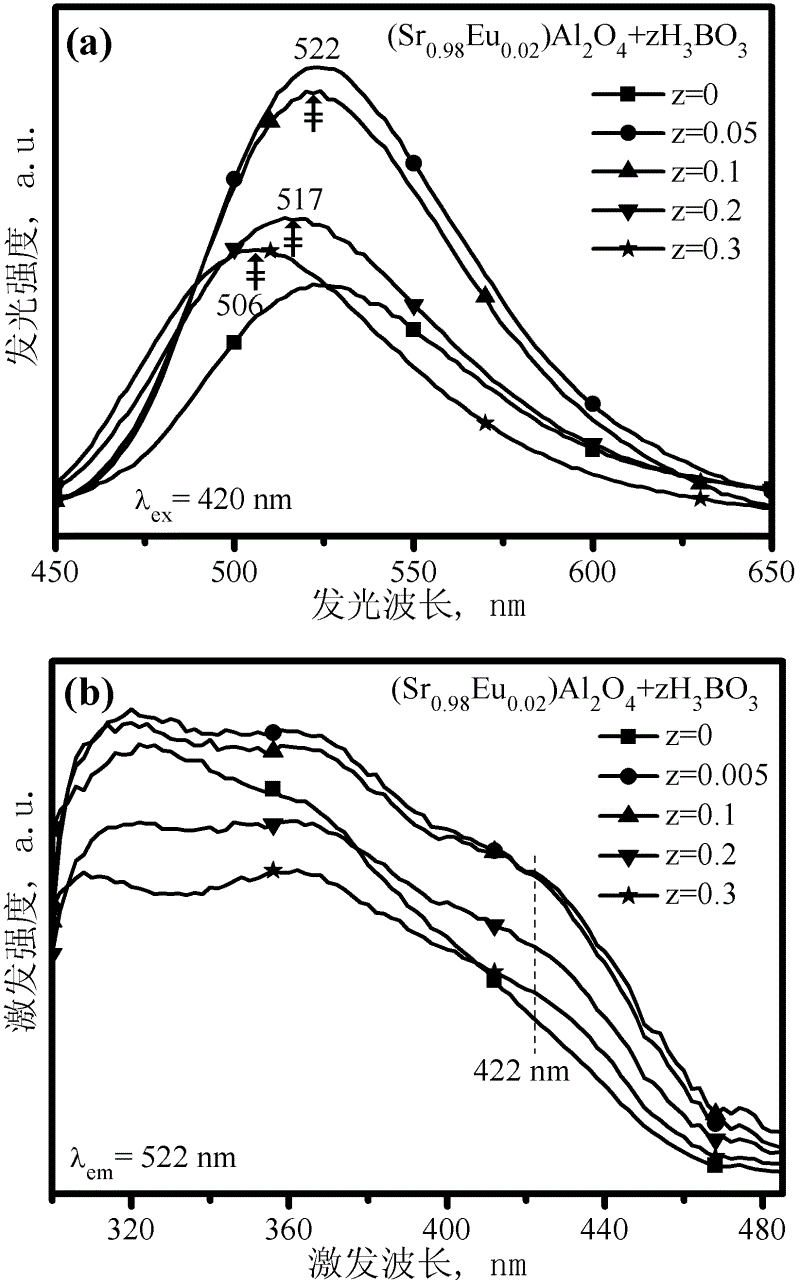

[0040] Embodiment 1: (Sr 0.98 Eu 0.02 )Al 2 o 4 +zH 3 BO 3

[0041] The values of z of samples prepared in this embodiment are 0, 0.05, 0.1, 0.2 and 0.3 respectively.

[0042] SrCO 3 、Al 2 o 3 、Eu 2 o 3 and H 3 BO 3 As raw materials, weigh various raw materials according to the ratio, use agate mortar to fully grind various raw materials to obtain a mixture, put the mixture into a crucible, press it tightly and cover it, and pre-fire it in the atmosphere at 800 ° C for 2 Hours, after being out of the furnace, carry out secondary grinding, then put it into the crucible, press it tightly and cover it, then put the crucible with the sample into the high temperature tube furnace, raise and lower the temperature at 5°C / min respectively, at the volume ratio H 2 / N 2 =5 / 95 Sintering at 1300°C for 4 hours under a reducing atmosphere. After being released from the furnace, put the sample into a ball mill jar according to the weight ratio—ball:sample:alcohol=10:1:3, and ...

Embodiment 2

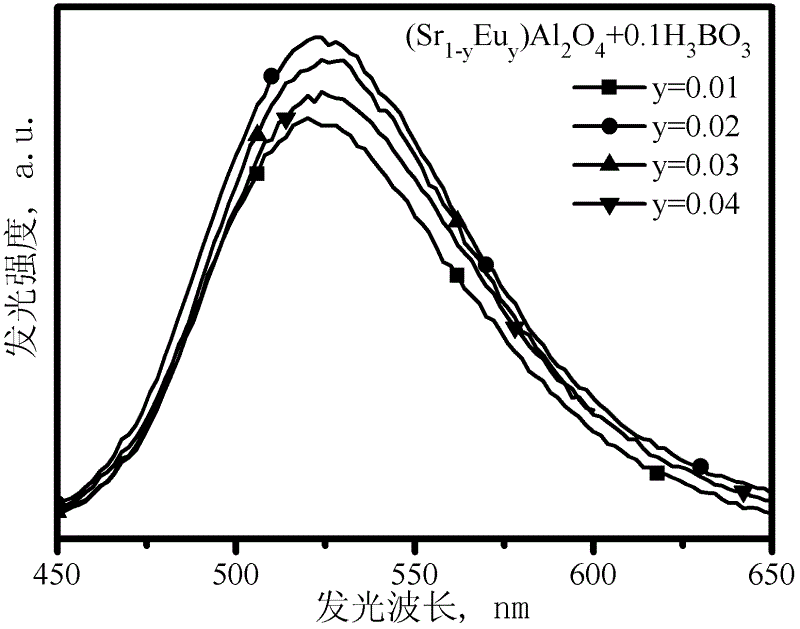

[0045] Embodiment 2: (Sr 1-y Eu y )Al 2 o 4 +0.1H 3 BO 3

[0046] The values of sample y prepared in this embodiment are 0.01, 0.02, 0.03 and 0.04 respectively.

[0047] The method for synthesizing fluorescent materials in this embodiment is the same as in Example 1, and the flux H 3 BO 3 Added amount z=0.1M.

[0048] Different concentrations of Eu 2+ Activate SrAl 2 o 4 The emission spectrum of a substance is as image 3shown, from which it can be seen that Eu 2+ The optimum concentration y=0.02. τ of the best sample 1 / 10 The afterglow decay time is 4.7 seconds, such as Figure 9 shown. Therefore, the use of such fluorescent materials can effectively compensate for the lack of luminescence during the dark period.

Embodiment 3

[0049] Embodiment 3: (Sr 0.98-x Eu 0.02 Y x ) Al 2 o 4 +0.15H 3 BO 3

[0050] The values of the samples x prepared in this embodiment are 0, 0.005, 0.01, 0.02 and 0.03, respectively.

[0051] The method for synthesizing fluorescent materials in this embodiment is the same as in Example 1, and the flux H 3 BO 3 Added amount z=0.15, use Y 3+ The raw material of the substance is Y 2 o 3 .

[0052] For 0.02M Eu 2+ Activate SrAl 2 o 4 substances, into which different Y 3+ , its emission spectrum varies with Y 3+ Concentration changes as Figure 4 shown, from which it can be seen that Y 3+ The optimal concentration x=0.01. τ of the best sample 1 / 10 The afterglow decay time is 6.5 seconds, such as Figure 9 shown. Therefore, the use of such fluorescent materials can effectively compensate for the lack of luminescence during the dark period.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com