Method for manufacturing closed loop superconducting coil by using magnesium diboride and closed loop superconducting coil

A technology of superconducting coils and magnesium diboride, which is applied in the direction of superconducting magnets/coils, coil manufacturing, magnetic objects, etc., can solve problems such as failures and research and development have just begun, and achieve operational simplification, market effects and social effects huge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

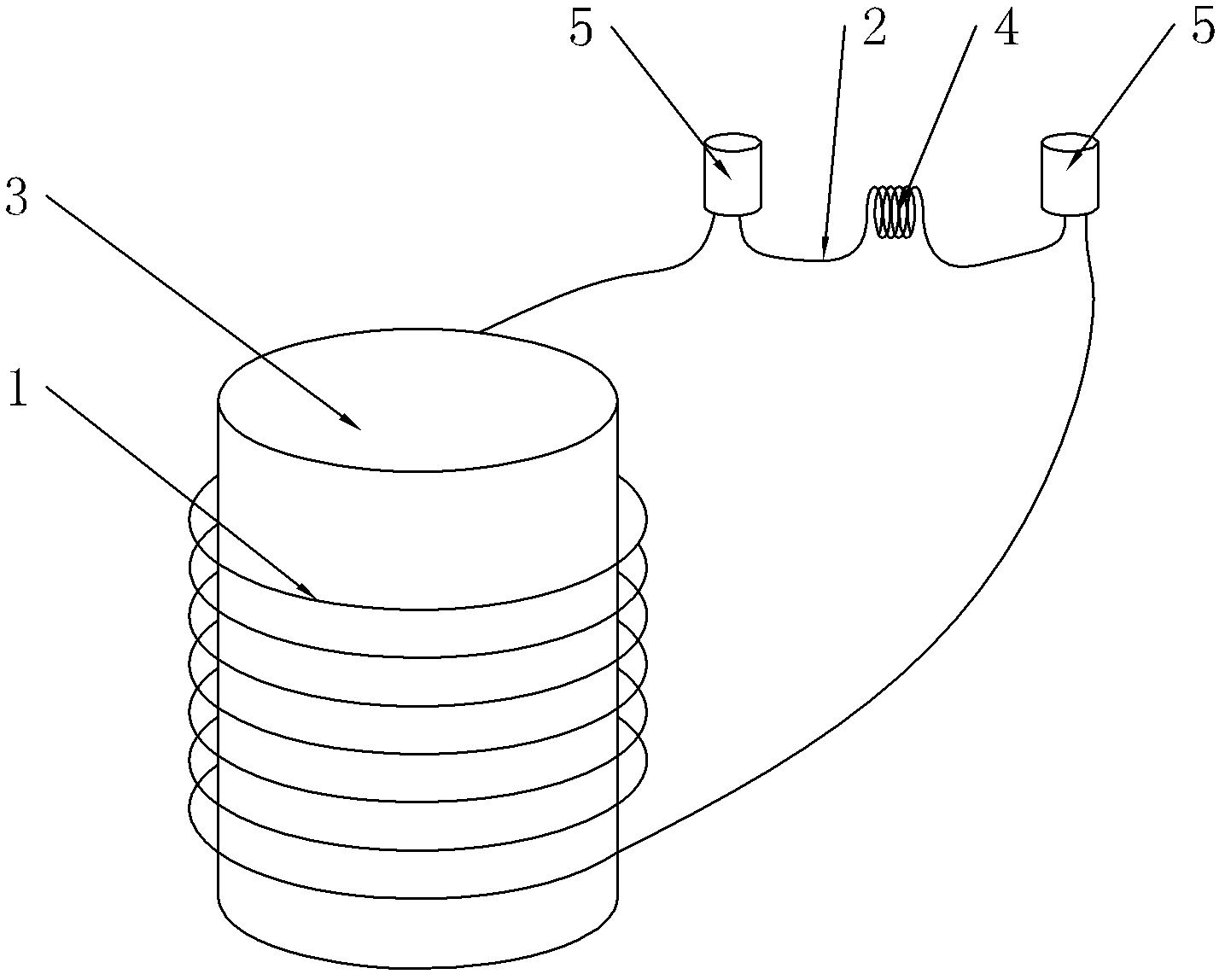

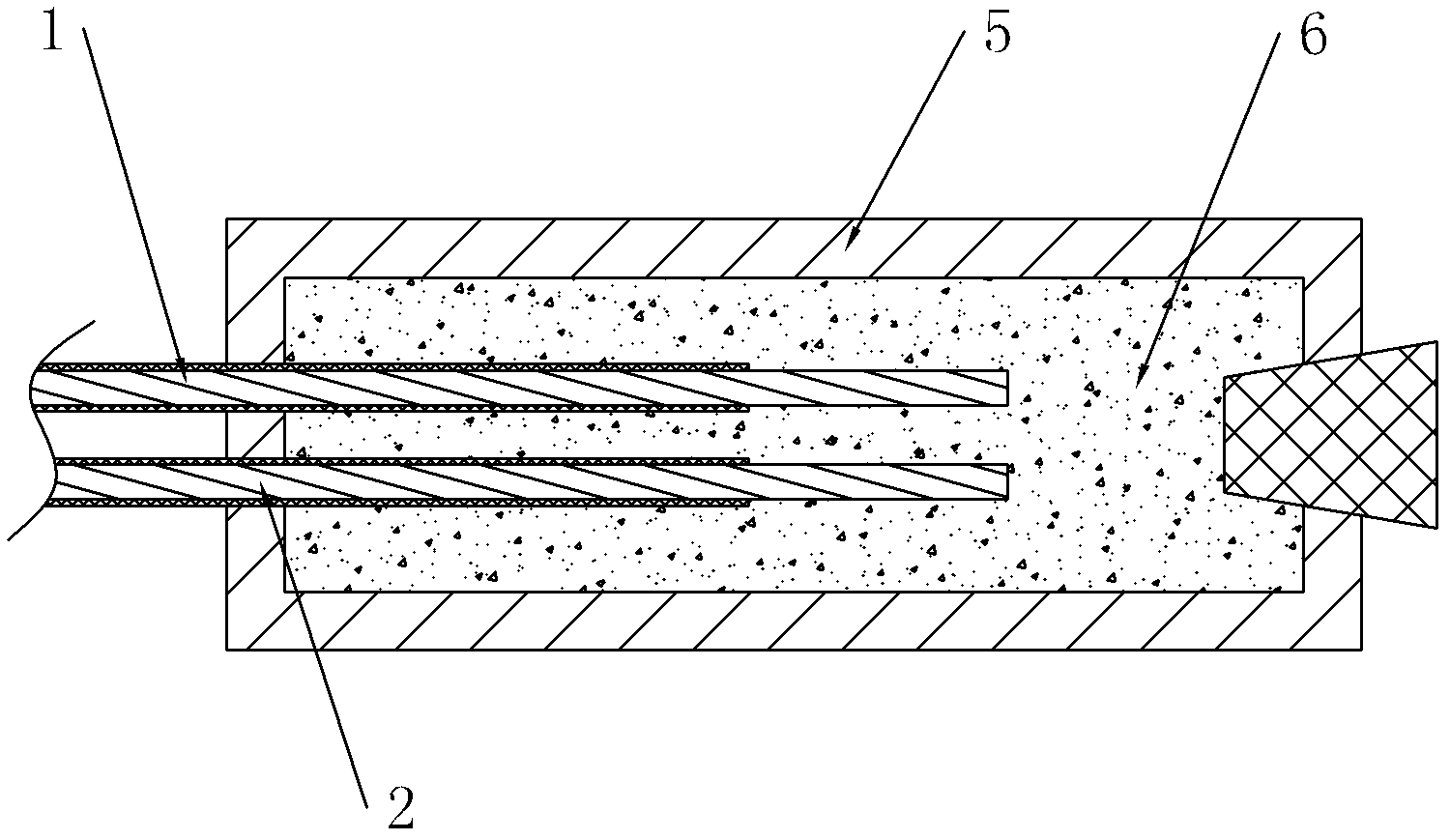

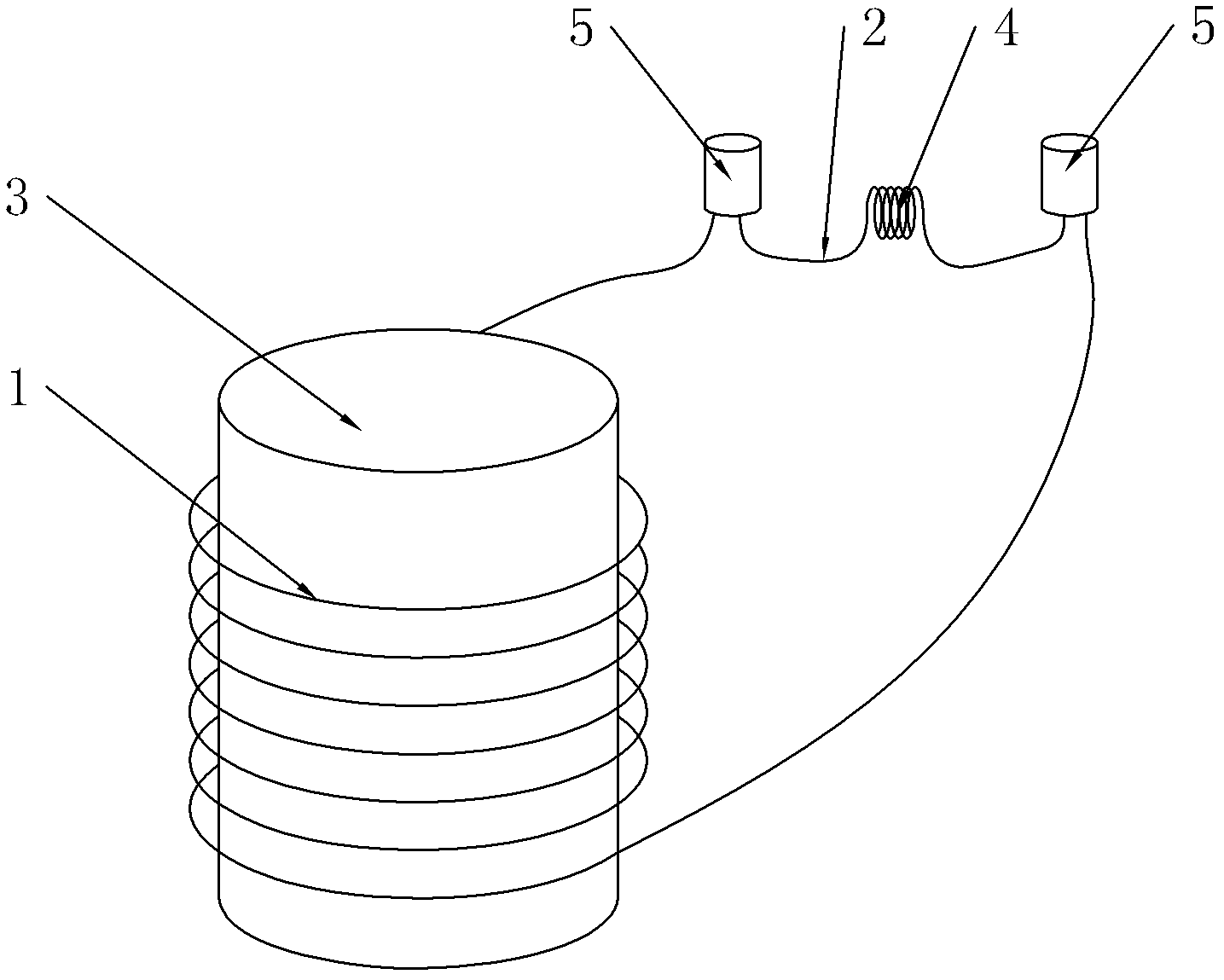

[0029] Embodiment 1: The present invention is a method for manufacturing a closed-loop superconducting coil with a magnesium diboride superconducting wire. The method has the following steps:

[0030] Step 1: Wind the unsintered magnesium diboride coil superconducting wire 1 on the coil frame 3 made of non-magnetic metal or ceramics by the solenoid coil winding method. The coil frame 3 in this embodiment is made of austenite Made of stainless steel, its diameter is 1m;

[0031] The above-mentioned coiled superconducting wire 1 is made of copper sheath material. Using an acidic solution to dissolve the copper sheaths at 5 mm from both ends of the coil superconducting wire 1 and the switching superconducting wire 2, so that the cores in the sheaths are exposed;

[0032] The above-mentioned acidic solution is nitric acid, sulfuric acid or hydrochloric acid, and the solvent of this embodiment is nitric acid with a concentration of 1 mol / L. After dissolving the jacket outside the...

Embodiment approach 2

[0038] Embodiment 2: The method for manufacturing a closed-loop superconducting coil from a magnesium diboride superconducting wire of the present invention, wherein the method has the following steps:

[0039] Step 1: Wind the unsintered magnesium diboride superconducting wire 1 on the skeleton 3 made of non-magnetic metal or ceramics by the solenoid coil winding method. The skeleton 3 of this embodiment is made of ceramics, and its diameter is 1M;

[0040] The above-mentioned coiled superconducting wire 1 is made of copper sheath material. Using an acidic solution to dissolve the copper sheaths at 5 mm from both ends of the coil superconducting wire 1 and the switching superconducting wire 2, so that the cores in the sheaths are exposed;

[0041] The above-mentioned acidic solution is nitric acid, sulfuric acid or hydrochloric acid, and the solvent of this embodiment is hydrochloric acid with a concentration of 1Mol / L. After dissolving the jacket outside the core, wash it ...

Embodiment approach 3

[0047] Embodiment 3: A method for manufacturing a closed-loop superconducting coil from a magnesium diboride superconducting wire of the present invention, wherein the method has the following steps:

[0048] Step 1: Wind the unsintered magnesium diboride superconducting wire 1 on the skeleton 3 made of non-magnetic metal or ceramics by the solenoid coil winding method. The skeleton 3 of this embodiment is made of austenitic stainless steel , whose diameter is 1.20M;

[0049] The above-mentioned coiled superconducting wire 1 is made of copper sheath material. Using an acidic solution to dissolve the copper sheaths at 5 mm from both ends of the coil superconducting wire 1 and the switching superconducting wire 2, so that the cores in the sheaths are exposed;

[0050] The above-mentioned acidic solution is nitric acid, sulfuric acid or hydrochloric acid, and the solvent in this embodiment is sulfuric acid with a concentration of 0.1Mol / L. After dissolving the jacket outside th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com