Micro-nano integrated processing technology based three-dimensional anti-drag micro-channel structure and preparation method thereof

An integrated processing and micro-channel technology, applied in the field of micro-machining, can solve problems such as complex process, high cost, and inability to realize three-dimensional drag-reducing micro-channel, and achieve simple process, low cost, and improved uniformity and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Obviously, many modifications and changes made by those skilled in the art based on the gist of the present invention belong to the protection scope of the present invention.

[0035] In order to make the above objects, features and advantages of the present invention more comprehensible, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

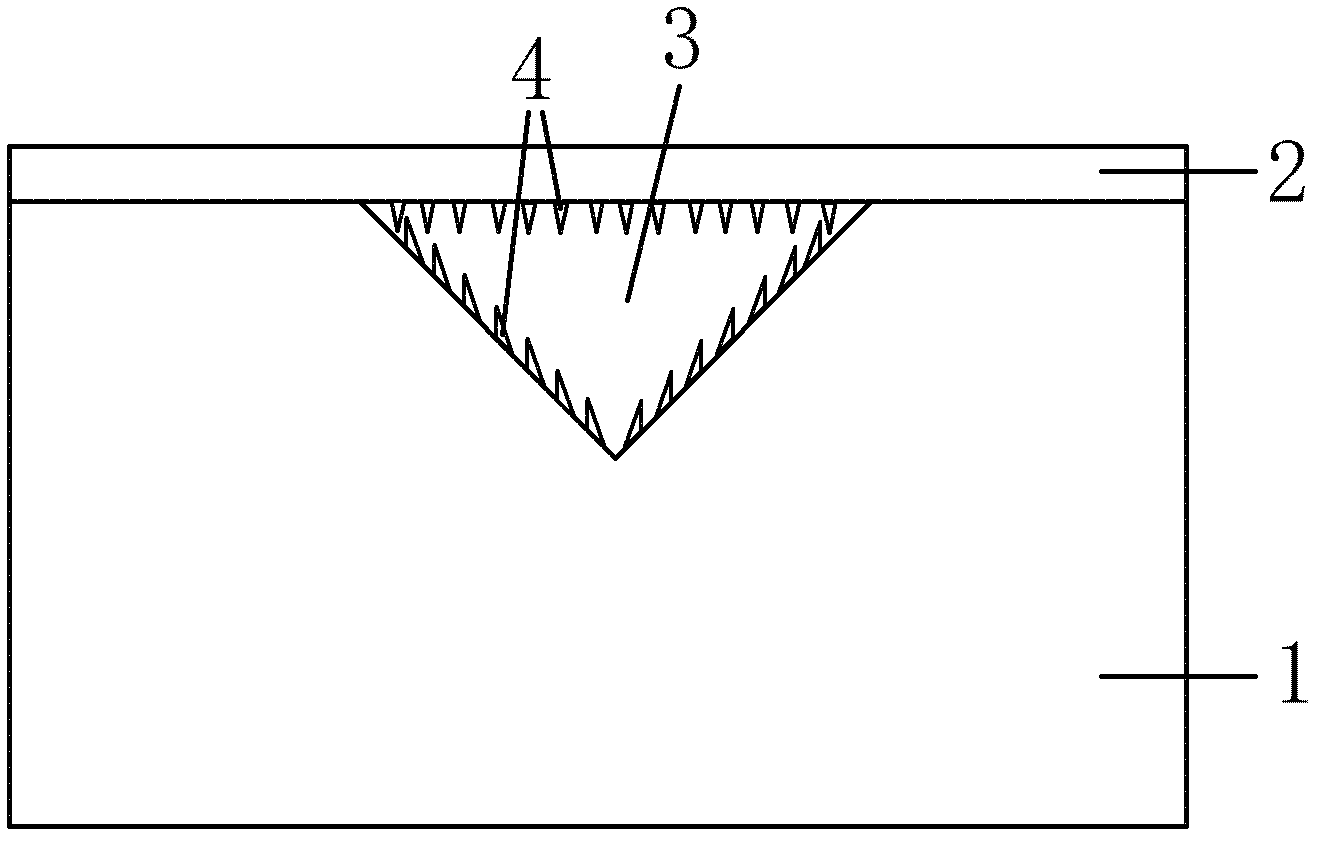

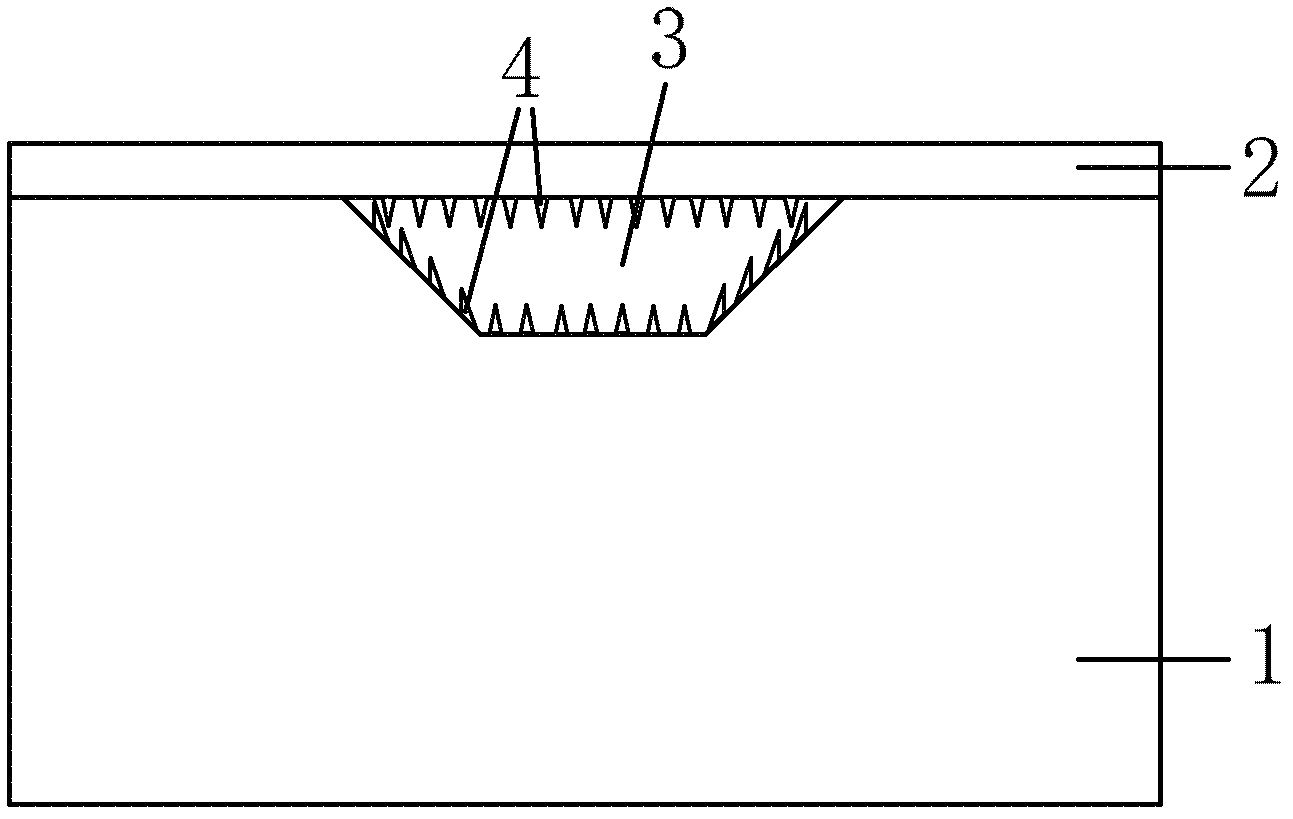

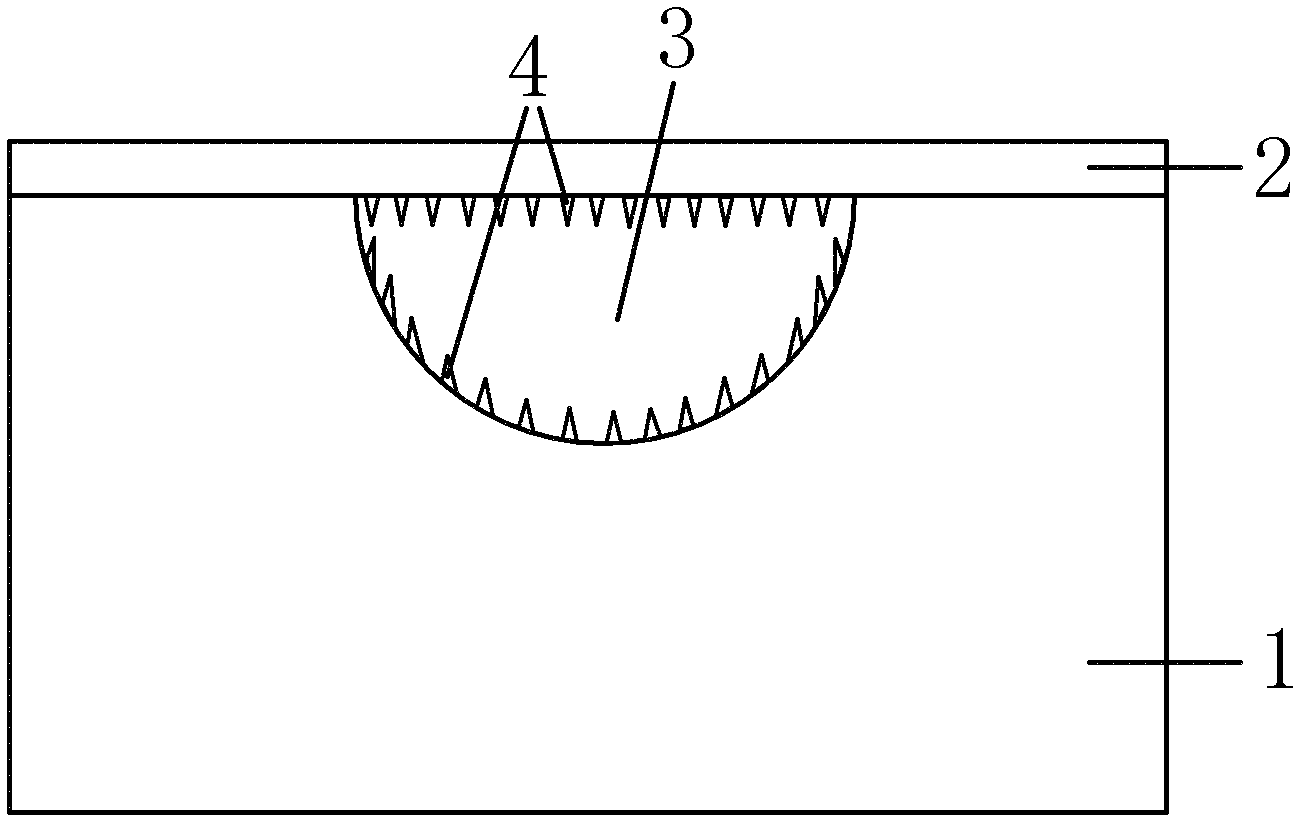

[0036] Below in conjunction with accompanying drawing 1 to Figure 5 A three-dimensional drag-reducing microchannel structure based on micro-nano integrated processing technology provided by the present invention and the specific steps of its preparation method are described.

[0037] Referring to Figure 1, Figure 1(a) to Figure 1(b) It is a structural schematic diagram of a three-dimensional drag-reducing microfluidic channel based on micro-nano integrated processing technology of the present invention, and its cross-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com