Recovery method of naphthalene in production of efficient naphthalene water reducing agent and required system thereof

A high-efficiency water-reducing agent and naphthalene recovery technology, applied in chemical instruments and methods, hydrocarbons, organic chemistry, etc., can solve the problems of long contact time between materials and hot steam, insufficient recovery rate, long recovery time, etc. The effect of low cost, short recovery period and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

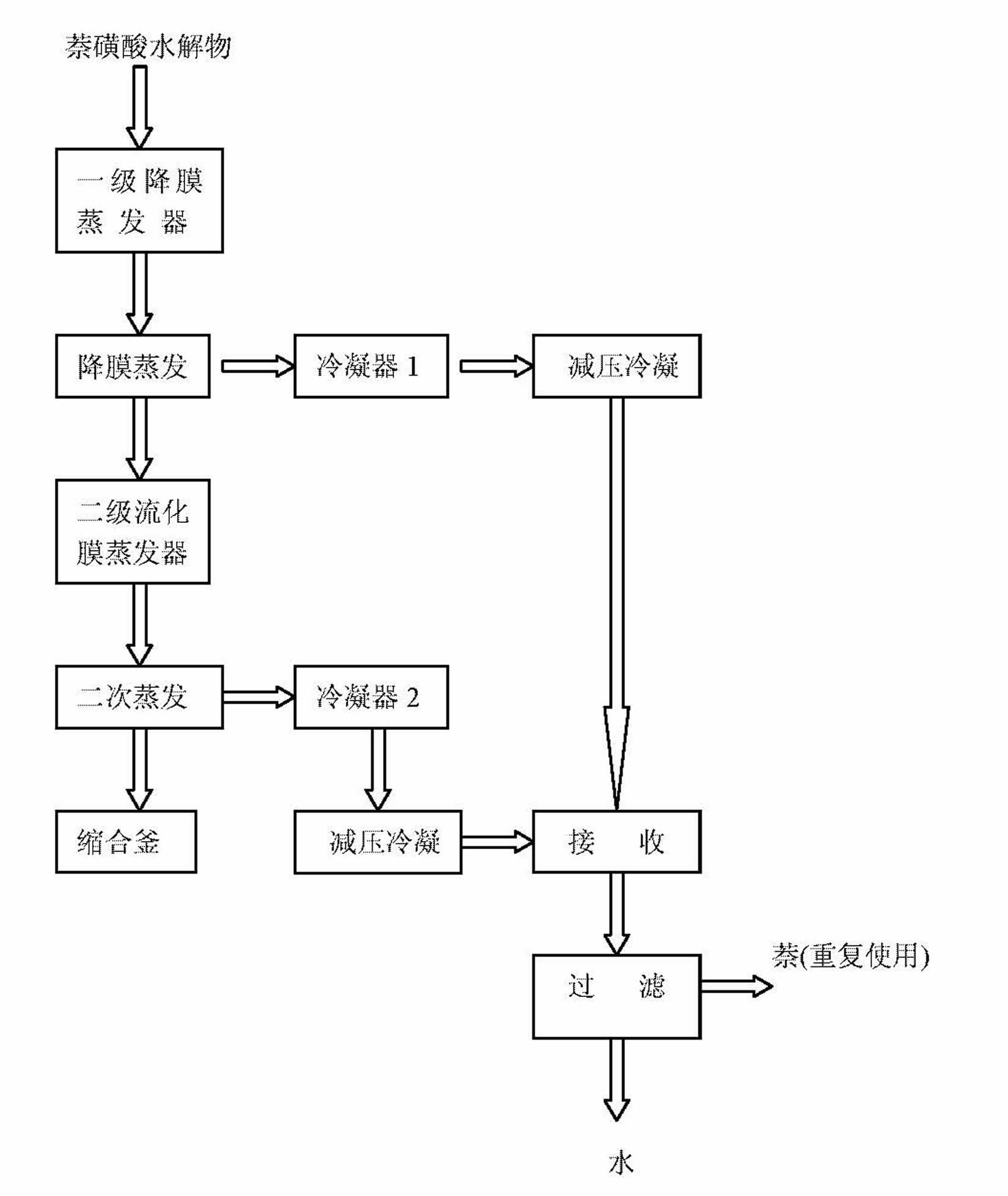

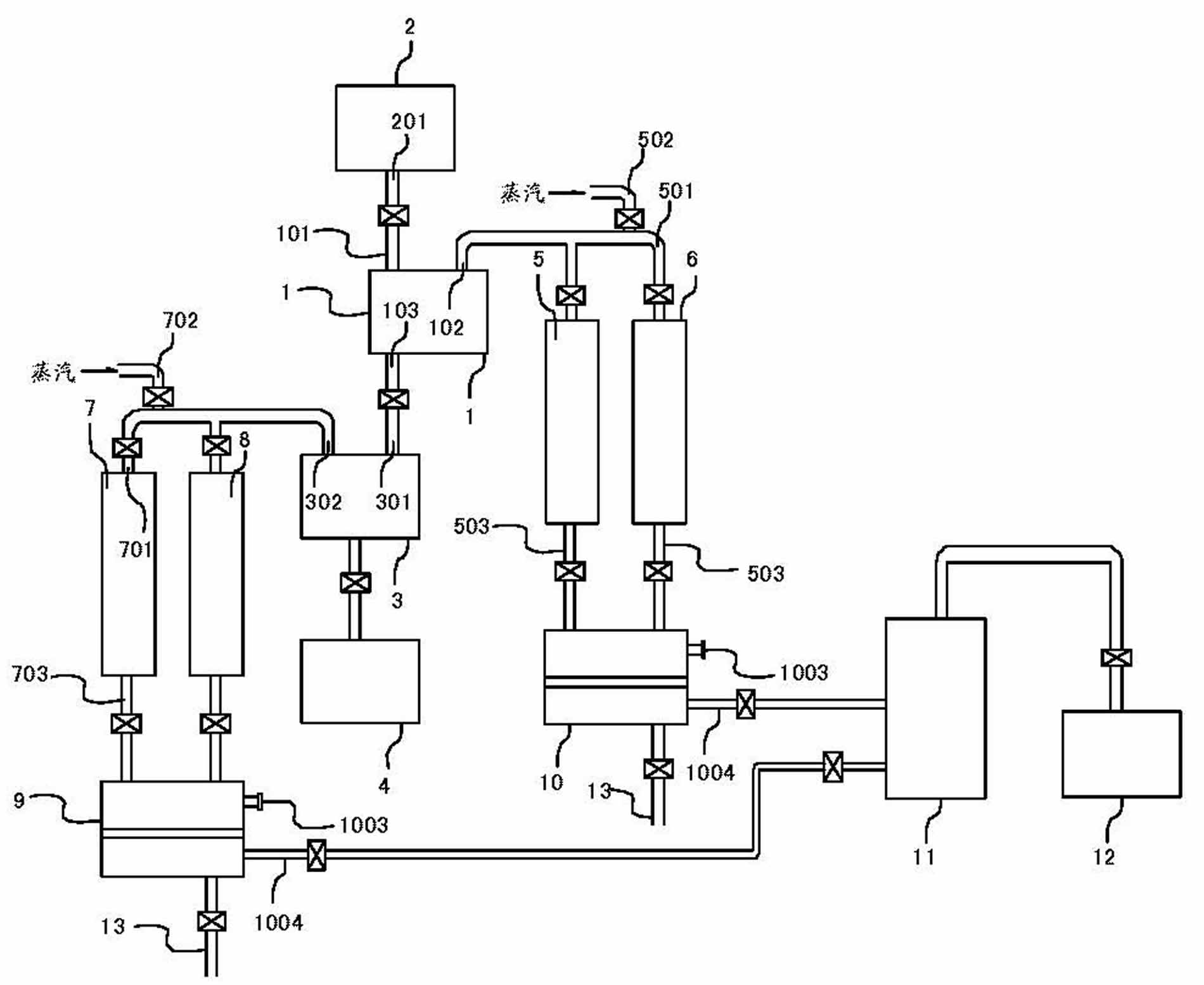

[0047] The naphthalenesulfonic acid hydrolyzate in the naphthalenesulfonic acid hydrolysis kettle passes through the first film evaporator 1 (first-stage falling film evaporator) at a speed of 30kg / min, and the azeotrope of naphthalene and water is condensed by the condenser and enters the first The naphthalene receiving filter 10 (receiving tank) can be recovered, and the material after falling film evaporation and removal of naphthalene in the first thin film evaporator 1 enters the second fluidized film evaporator 3 (secondary fluidized evaporator), and the naphthalene is removed for the second time. The material after the second removal of naphthalene enters the condensation tank for condensation reaction. The system pressure is 0.04MPa and the temperature is 98 degrees. The naphthalene removal time of each kettle material is 100 minutes.

Embodiment 2

[0049] The naphthalenesulfonic acid hydrolyzate in the naphthalenesulfonic acid hydrolysis kettle passes through the first film evaporator 1 (first-stage falling film evaporator) at a speed of 33kg / min, and the azeotrope of naphthalene and water passes through the condenser and enters the first The naphthalene receiving filter 10 (receiving tank) can be recovered, and the material after falling film evaporation and removal of naphthalene in the first thin film evaporator 1 enters the second fluidized film evaporator 3 (secondary fluidized evaporator), and the naphthalene is removed for the second time. The material after the second removal of naphthalene enters the condensation tank for condensation reaction. The system pressure is 0.037MPa and the temperature is 96 degrees. The naphthalene removal time of each kettle material is 90 minutes.

Embodiment 3

[0051] The naphthalenesulfonic acid hydrolyzate in the naphthalenesulfonic acid hydrolysis kettle passes through the first film evaporator 1 (first-stage falling film evaporator) at a speed of 37kg / min, and the azeotrope of naphthalene and water passes through the condenser and enters the first The naphthalene receiving filter 10 (receiving tank) can be recovered, and the material after falling film evaporation and removal of naphthalene in the first thin film evaporator 1 enters the second fluidized film evaporator 3 (secondary fluidized evaporator), and the naphthalene is removed for the second time. The material after the second removal of naphthalene enters the condensation tank for condensation reaction. The system pressure is 0.035MPa and the temperature is 94 degrees.

[0052] The naphthalene removal time of each kettle material is 80 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com