Heavy-duty anticorrosive polyaniline coating and preparation method thereof

A polyaniline and heavy-duty anti-corrosion technology, applied in anti-corrosion coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problems of inapplicable anti-corrosion treatment of large metal parts, economic benefits to be improved, and inapplicability to industrial production. , to achieve the effect of improving the intercalation effect, enhancing the anti-corrosion performance and reducing the surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

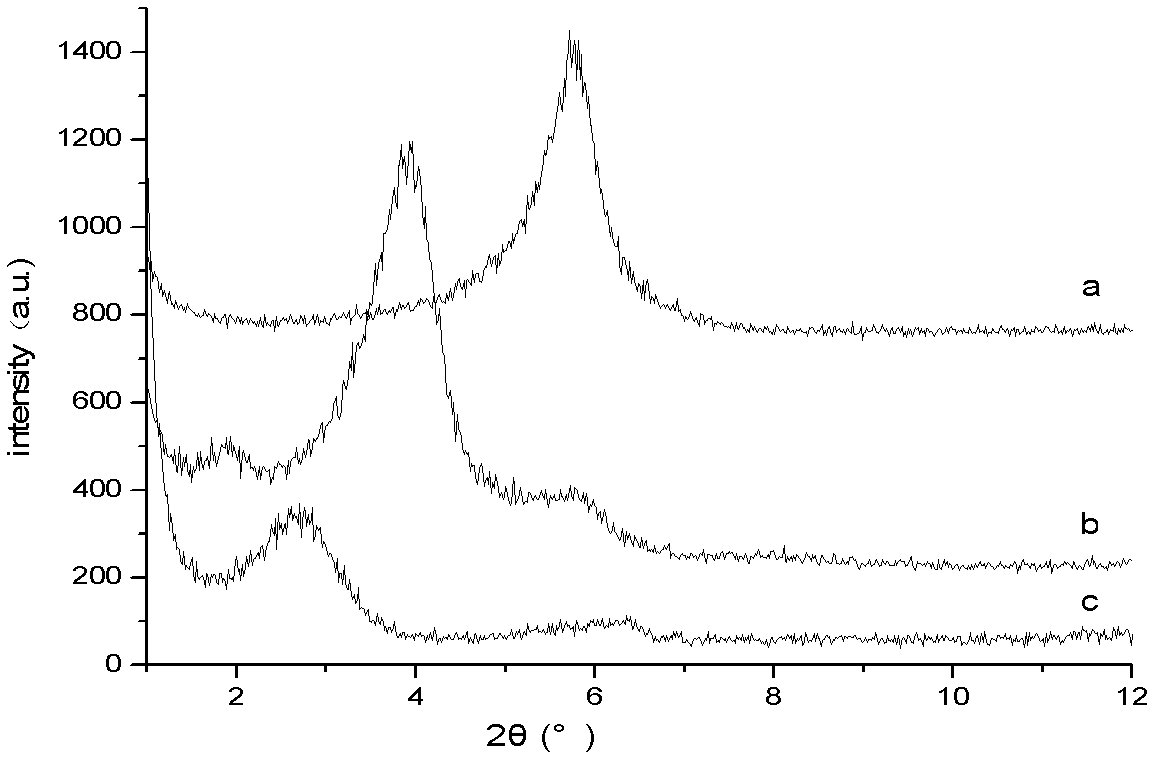

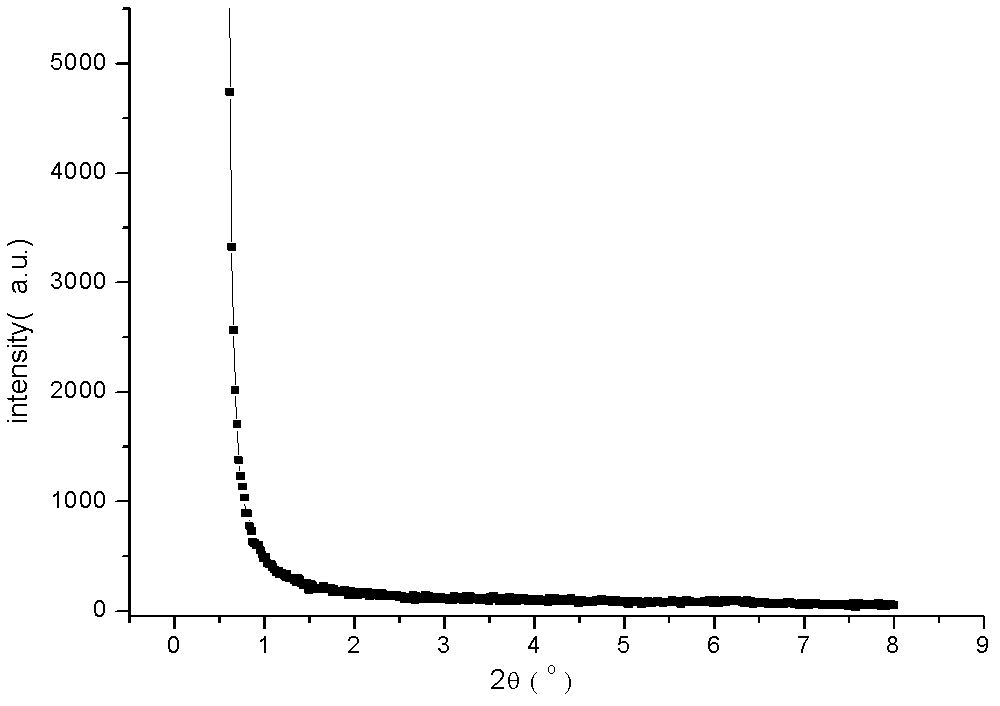

[0045] Step 1: Add 50g of montmorillonite to 500mL of distilled water, stir evenly with a mixer at a speed of 800r / min at 60°C to form a suspension system, and let it stand for 24 hours to remove non-swellable impurities in the montmorillonite. Add a small amount of 1mol / L hydrochloric acid solution into the suspension, control the pH value of the suspension at 1 to 3, and perform proton activation to form a suspension for later use; 5 g of bis[N,N-dimethyldodecyl ( Octadecyl) amido] ethyl bis ammonium chloride was dissolved in 50mL distilled water and slowly added dropwise to the suspension, stirred while dropping for 4h, and then centrifuged to obtain the organic activated montmorillonite suspension of intercalation structure , filtered, vacuum-dried at 60°C for 12 hours, and passed through an 800-mesh sieve after grinding to obtain an organic activated montmorillonite powder with a particle size of 15-20 μm and an intercalation structure;

[0046] Step 2: Add 50g of organic...

Embodiment 2

[0053] Step 1. Add 50g of montmorillonite to 500mL of distilled water, stir evenly with a mixer at a speed of 800r / min at 60°C to form a suspension system, and let it stand for 24 hours to remove non-swellable impurities in the montmorillonite. Add a small amount of 1mol / L sulfuric acid solution into the suspension, control the pH value of the suspension at 1-3, carry out proton activation, and form a suspension for later use; then add 5g of bis(2-hydroxy-5-nonylphenyl) Dissolve methane-oxygen-bis(2-hydroxypropyltrihydroxyethyl)ammonium chloride in 50mL distilled water and slowly add it dropwise to the standby suspension, stir for 3 hours while adding it, and then centrifuge to obtain the organic activation of the intercalated structure The montmorillonite suspension was left to stand, filtered, vacuum-dried at 60°C for 20 hours, ground and passed through a 800-mesh sieve to obtain an organic activated montmorillonite powder with an intercalation structure with a particle size ...

Embodiment 3

[0059] Step 1. Add 50g of montmorillonite to 500mL of distilled water, stir evenly with a mixer at a speed of 800r / min at 60°C to form a suspension system, and let it stand for 24 hours to remove non-swellable impurities in the montmorillonite. Add a small amount of 1mol / L sulfosalicylic acid solution into the suspension, control the pH value of the suspension at 1 to 3, and perform proton activation to form a suspension for later use; dimethyl / hexadecylamidopropyl dimethyl)ammonium chloride] dissolved in 50mL distilled water and slowly added dropwise to the standby suspension, stirred for 4h while adding dropwise, and then centrifuged to obtain the organic activation of the intercalation structure The montmorillonite suspension was left to stand, filtered, vacuum-dried at 60°C for 24 hours, ground and passed through an 800-mesh sieve to obtain an organic activated montmorillonite powder with an intercalation structure with a particle size of 15-20 μm.

[0060]Step 2. Add 50g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com