Method for preparing stationary phase coating material for trace substance identification and application of material

A coating material and stationary phase technology, applied in the field of stationary phase materials for chromatographic detection, can solve the problems of poor film-forming property and high melting point of cyclodextrin, and achieve the effects of low column loss rate, large adsorption capacity and uniform film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

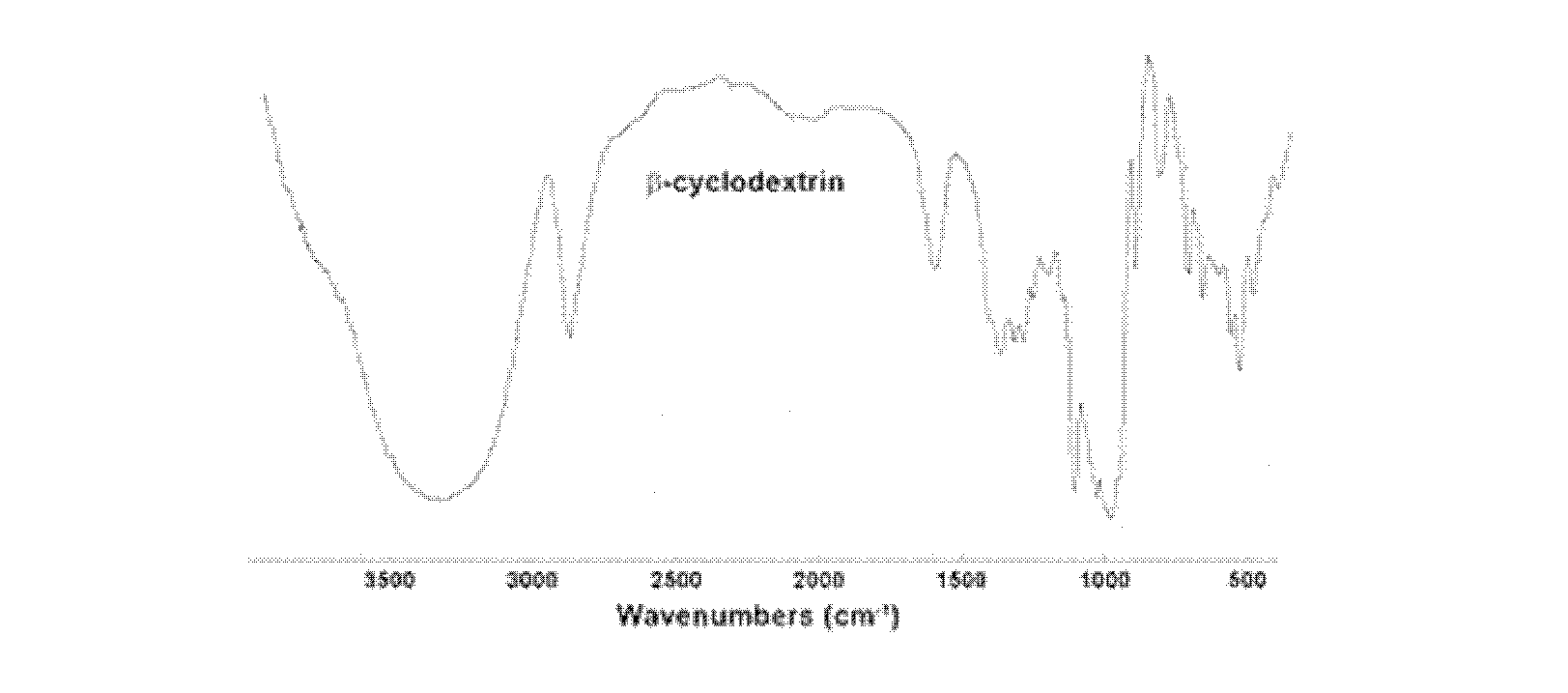

[0037] Preparation of fully dried cyclodextrin: Add 100ml of distilled water to a 300ml beaker and heat to a slight boiling point. Weigh 5 g of β-cyclodextrin, stir and heat to dissolve, filter while hot, and the filtrate crystallizes to obtain β-cyclodextrin crystals. Filter off the water, put β-cyclodextrin into a 50ml small beaker, place it in a vacuum drying oven at 110°C-120°C for 1 hour, and store in a desiccator.

[0038] The preparation method of fully dried THF is: metal sodium is refluxed until the benzophenone indicator turns blue.

[0039] Preparation method of stationary phase coating material for identification of trace substances: Take a Contes tube, fully dry, and under nitrogen protection, add MeHSi(CH 2 -CH=CH 2 ) 2 5ml, THF 10ml, 3 drops of Karstedt catalyst, react at 80°C for 8 hours. Evaporate the solvent to obtain HBP-allyl.

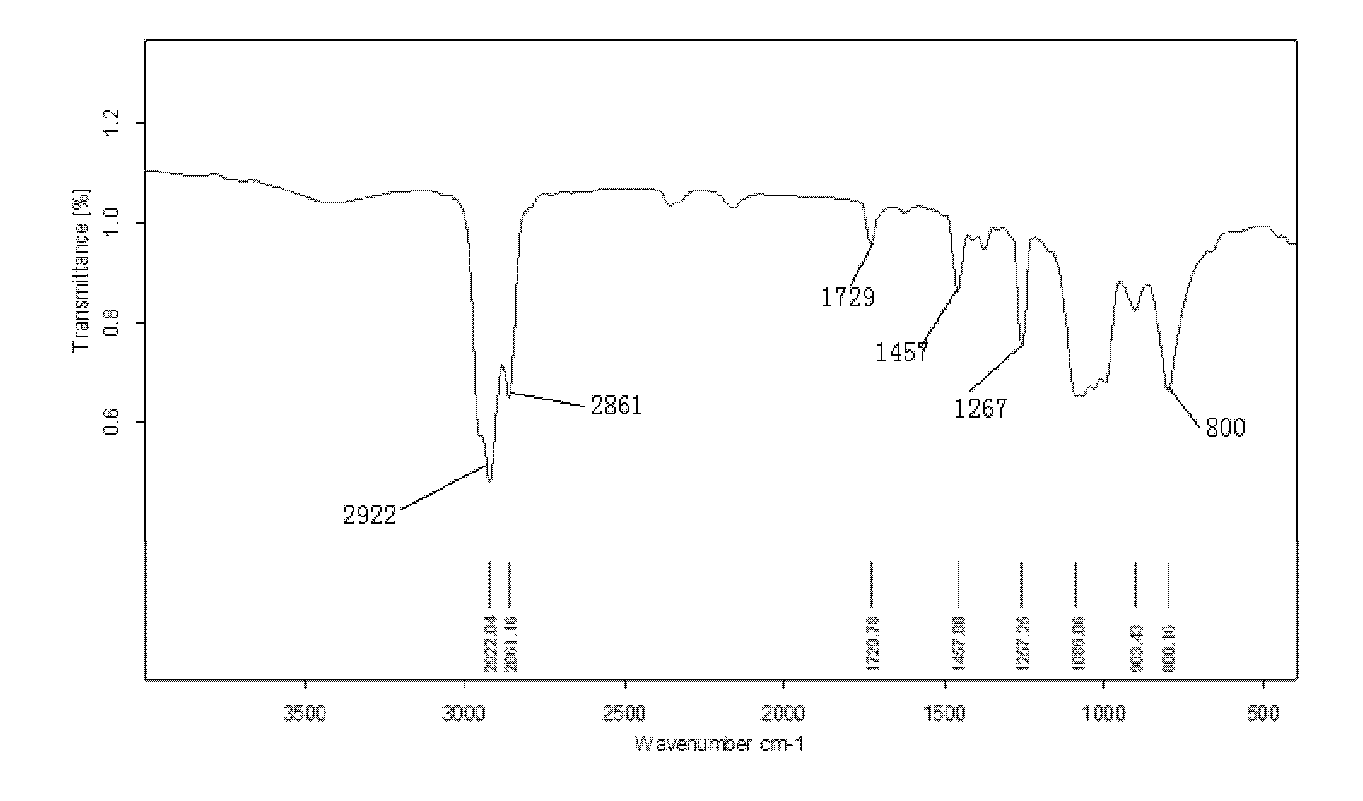

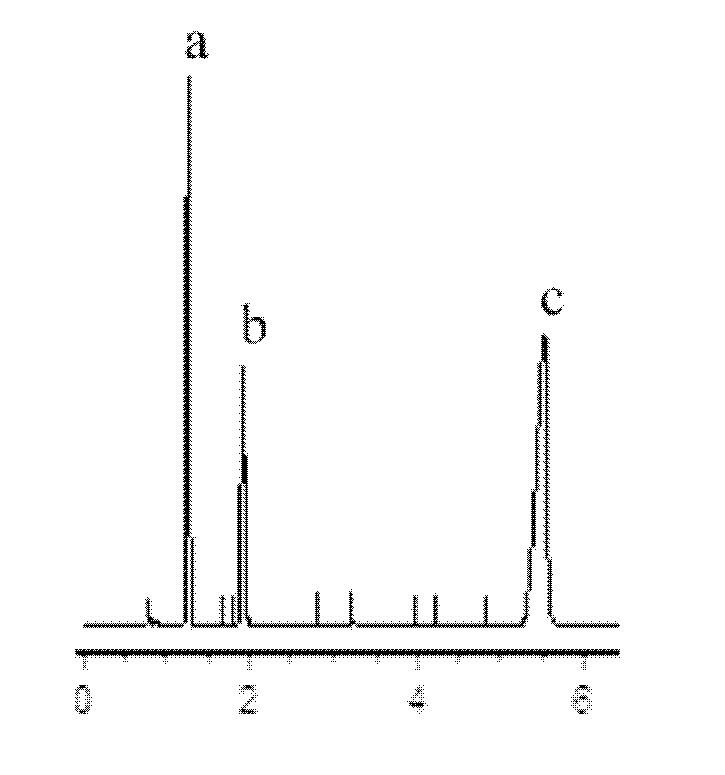

[0040] Take HBP-allyl 2ml, MeHSiCl 2 4ml, THF 10ml, 3 drops of Karstedt catalyst, react at 80℃ for 8 hours; infrared monitoring allyl g...

Embodiment 2

[0044] Preparation of fully dried cyclodextrin: Add 100ml of distilled water to a 300ml beaker and heat to a slight boiling point. Weigh 5 g of β-cyclodextrin, stir and heat to dissolve, filter while hot, and the filtrate crystallizes to obtain β-cyclodextrin crystals. Filter off the water, put β-cyclodextrin into a 50ml small beaker, place it in a vacuum drying oven at 110°C-120°C for 1 hour, and store in a desiccator.

[0045] The preparation method of fully dried n-hexane is: metal sodium is refluxed until the benzophenone indicator turns blue.

[0046] Preparation method of stationary phase coating material for identification of trace substances: Take a Contes tube, fully dry, and under nitrogen protection, add MeHSi(CH 2 -CH=CH 2 ) 2 5ml, 10ml n-hexane, 3 drops of Karstedt catalyst, react at 80°C for 8 hours. Evaporate the solvent to obtain HBP-allyl. HBP-allyl 2ml, MeHSiCl 2 4ml, 10ml of n-hexane, 3 drops of chloroplatinic acid catalyst, reacted at 90℃ for 6 hours; infrared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com