Zinc-plated trivalent chromium blue-white passivator

A passivating agent, blue-white technology, applied in the coating process of metal materials, etc., can solve the problems of not meeting the electroplating requirements of ordinary hardware, corrosion resistance and appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific preparation steps of this embodiment are as follows:

[0016] a. Prepare a common low-cyanide zinc plating solution and adjust the pH value for electroplating.

[0017] b. After a certain period of time, take out the sample, and conduct passivation treatment after light exposure in 3% nitric acid. The passivation time is 8-20s.

[0018] c. Observe the color of the conversion coating layer, and conduct a neutral salt spray test.

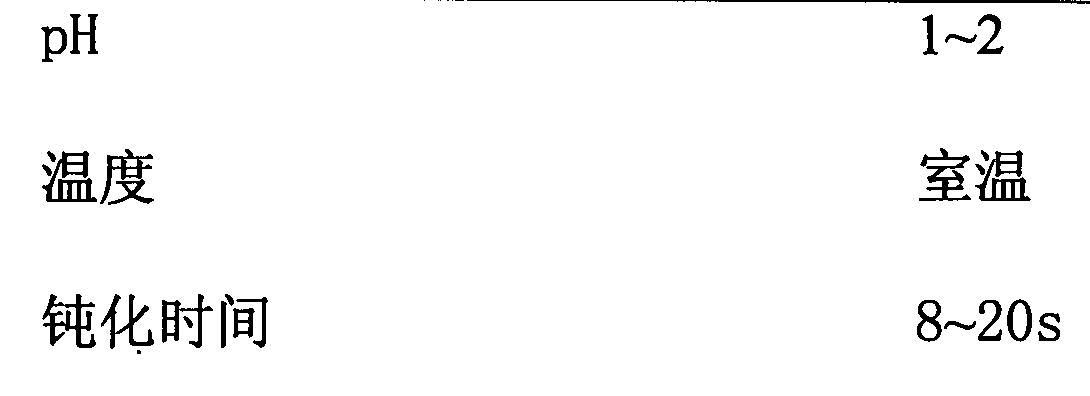

[0019] A kind of galvanized trivalent chromium blue-white passivating agent process specification is:

[0020]

[0021]

[0022] NOTE: The passivation time can be shortened when there is agitation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com