Method of protection treatment on millimeter-wave circuit component by use of vacuum vapor deposition membrane

A circuit component and vapor deposition technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problems of complex hermetic packaging structure design, large component volume and weight, long manufacturing cycle, etc., and achieve lightweight , high reliability, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

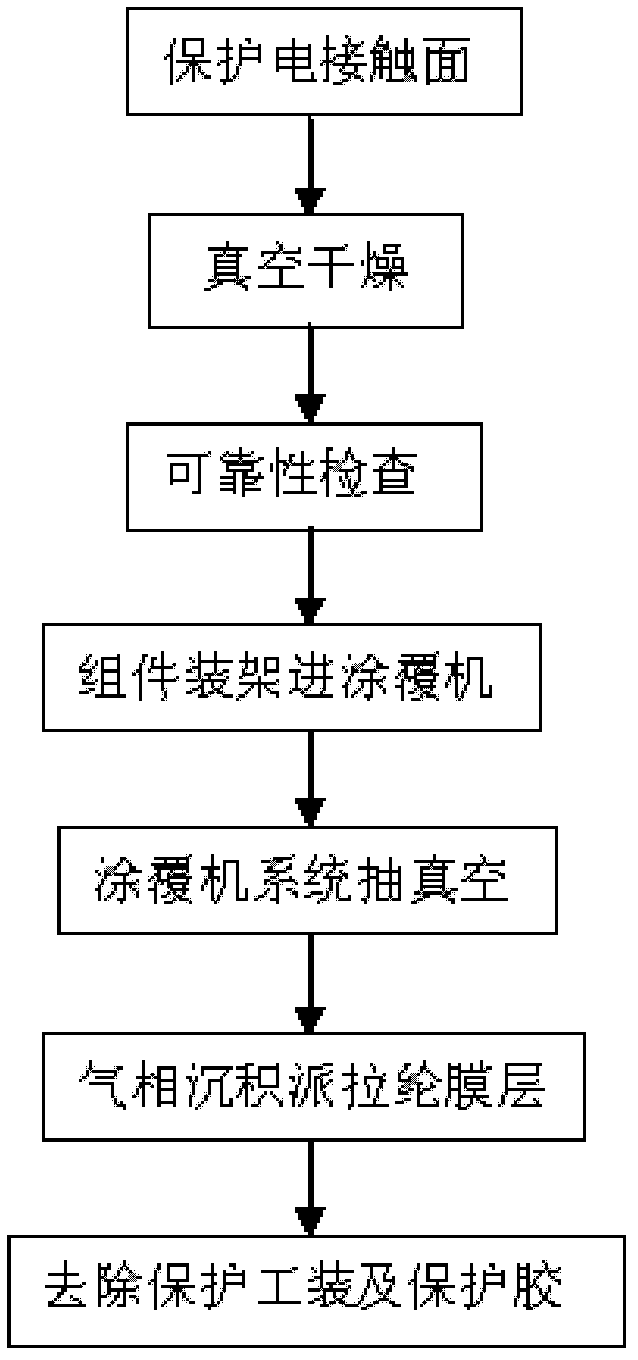

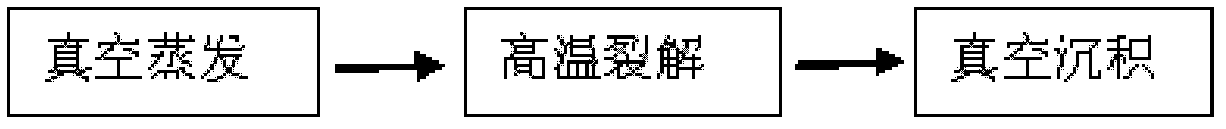

[0020] refer to figure 1 . In the manufacturing process of the millimeter wave circuit component, the protection treatment process of the present invention is usually added after the processing and performance debugging of the millimeter wave circuit component are completed. 1. Protect the electrical contact surface; 2. Vacuum drying; 3. Reliability inspection; 4. Mount the components into the coating machine; 5. Vacuumize the coating machine system; Protective tooling and protective glue. The main steps include:

[0021] a) In a clean environment, use protective tooling, pressure-sensitive tape or peelable glue to protect the unprotected parts (electrical contact surfaces) of the millimeter-wave circuit components that need to be protected;

[0022] b) Use a vacuum oven to vacuum-dry the millimeter-wave circuit components to be coated;

[0023] c) In a clean environment, use a 5x magnifying glass to check whether the mask protection of the electrical contact surface meets...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com