Distributed feedback laser array

A laser array and distributed feedback technology, which is applied to laser devices, semiconductor laser devices, optical resonator structures, etc., can solve the problems of lack of low-cost and high-reliability distributed feedback laser arrays, and achieve easy integration and fabrication, simplifying the process. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawings and examples.

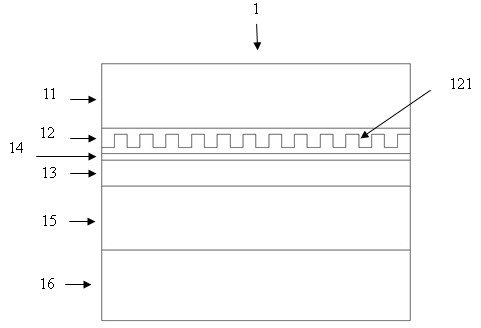

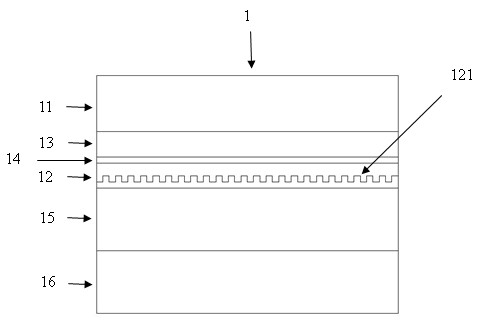

[0027] Such as figure 1 As shown, a distributed feedback laser array is composed of a plurality of distributed feedback lasers 2 arranged in parallel on the same semiconductor epitaxial wafer 1; the semiconductor epitaxial wafer 1 includes an upper cladding layer 11, an active layer from top to bottom 12. The spacer layer 14, the refractive index control layer 13, the lower cladding layer 15 and the substrate 16, the Bragg grating 121 for forming distributed feedback is arranged in the active layer 12 or the refractive index control layer 13; the period of the Bragg grating 121 is Keep consistent on the whole semiconductor epitaxial wafer 1 .

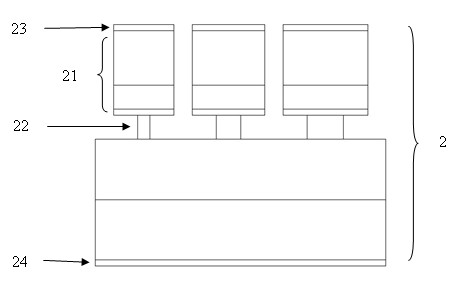

[0028] Such as figure 2 As shown, all the distributed feedback lasers 2 in a distributed feedback laser array are perpendicular to the Bragg grating 121; the upper cladding layer 11, the active layer 12 and the space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com