Curable resin composition and cured product thereof

A curable resin and composition technology, applied in the direction of electric solid-state devices, semiconductor/solid-state device parts, electrical components, etc., can solve the problems of LED products such as reduced illumination and durability problems, and achieve excellent optical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0218] Hereinafter, the present invention will be described in more detail through synthesis examples and examples. In addition, this invention is not limited to these synthesis examples and Examples. In addition, in the following synthesis examples and Examples, "part" means "weight part", and "%" means "weight%". In addition, each physical property value in an Example was measured by the following method.

[0219] (1) Molecular weight: The molecular weight measured by the gel permeation chromatography (GPC) method under the following conditions was converted into polystyrene, and the weight average molecular weight was calculated.

[0220] Various conditions of GPC

[0221] Manufacturer: Shimadzu Corporation

[0222] Chromatographic column: guard column SHODEX GPC, LF-G, LF-804 (3 pieces)

[0223] Flow rate: 1.0ml / min

[0224] Column temperature: 40°C

[0225] Solvent used: THF (tetrahydrofuran)

[0226] Detector: RI (Differential Refractive Detector)

[0227] (2) Ep...

Synthetic example 1

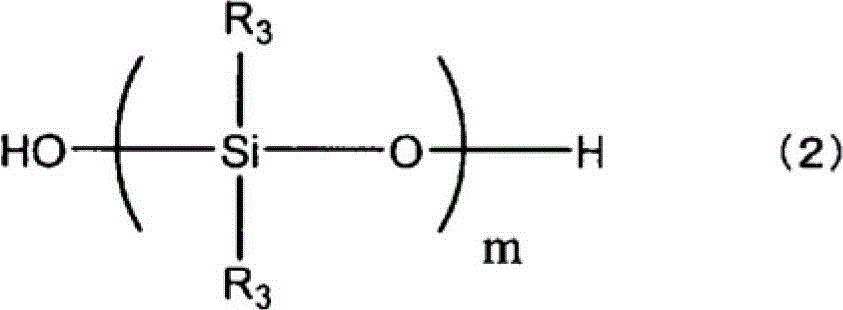

[0230] As the manufacturing process (i), 106 parts of β-(3,4 epoxycyclohexyl) ethyl trimethoxysilane, 234 parts of silanol-terminated methyl phenyl silicone oil ( Silanol equivalent 850, calculated by half of the weight-average molecular weight measured by GPC), 18 parts of 0.5% potassium hydroxide (KOH) methanol solution (0.09 parts in terms of KOH parts) are packed into the reaction vessel, and the bath The temperature was set at 75°C and ramped up. After raising the temperature, it was allowed to react under reflux for 8 hours.

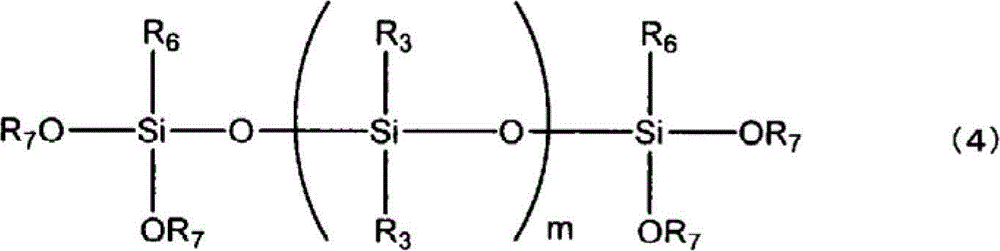

[0231] As the production process (ii), after adding 305 parts of methanol, 86.4 parts of 50% distilled water-methanol solution was added dropwise over 60 minutes, and it was made to react at 75 degreeC under reflux for 8 hours. After the reaction, neutralize with 5% sodium dihydrogen phosphate aqueous solution, and then carry out distillation recovery of methanol at 80°C. Add 380 parts of methyl isobutyl ketone (MIBK), and repeat washing with wat...

Synthetic example 2

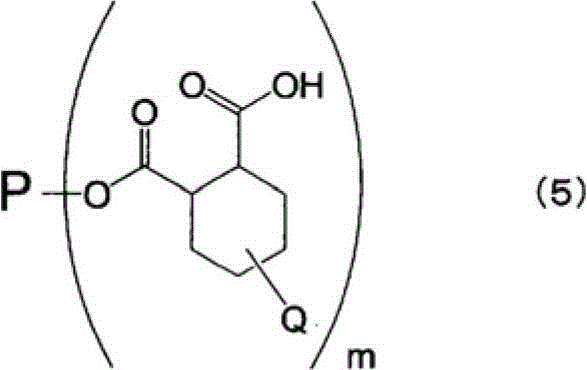

[0233] 20 parts of tricyclodecane dimethanol and 100 parts of methylhexahydrophthalic anhydride (manufactured by Shinnihon Rika Co., Ltd., リカシツド MH , hereinafter referred to as acid anhydride (H-1)), reacted at 40°C for 3 hours, then heated and stirred at 70°C for 1 hour (confirmed the disappearance of tricyclodecane dimethanol (less than 1 area %) by GPC), obtained by This gave 120 parts of curing agent composition (T-1) containing polyhydric carboxylic acid (B-1) and acid anhydride (H-1). The obtained curing agent composition (T-1) is a colorless liquid resin, and the purity measured by GPC is that polycarboxylic acid (B-1; following formula (7)) is 55 area %, acid anhydride (H- 1) is 45 area%. In addition, the functional group equivalent was 201 g / eq. In addition, the viscosity at 25° C. was 18900 mPa·s (E-type viscometer).

[0234]

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com