Negative electrode for secondary battery, and secondary battery using same

A secondary battery and negative electrode technology, applied in the direction of secondary batteries, battery electrodes, batteries, etc., can solve the problems of shortened cycle life, battery damage, poor adhesion, etc., and achieve the effect of excellent performance balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Lump coke (green coke) produced by using refined pitch obtained by removing quinoline-insoluble components from coal-based heavy oil and heat-treating at 500°C for 24 hours by the delayed coking method is carried out with a jet mill. Finely pulverized and sized to obtain green coke powder with an average particle diameter of 9.9 μm.

[0085] The lump-shaped green coke obtained as above is heat-treated at a temperature from 700° C. near the inlet to 1500° C. (the highest reaching temperature) near the outlet through a rotary kiln for more than 1 hour to obtain lump-shaped calcined coke. Finely pulverize and sizing, to obtain calcined coke powder with an average particle size of 9.5 μm.

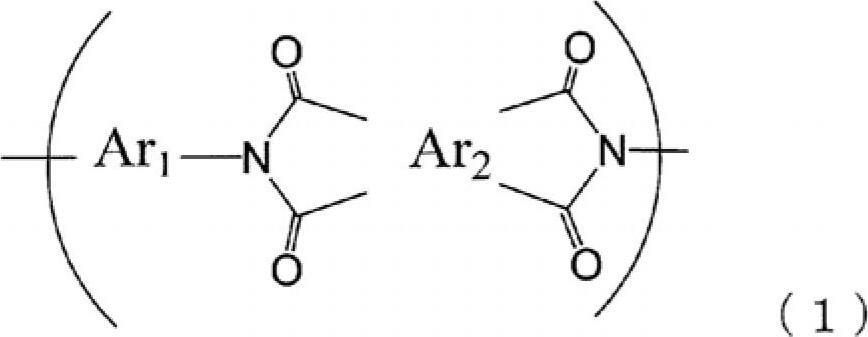

[0086] To the total of 50 parts by mass of green coke powder and 50 parts by mass of calcined coke powder (100 parts by mass of coke powder) obtained as above, phosphoric acid ester (14 mass % active phosphorus solid resin: Sanko Corporation trade name HCA, chemical name : 9,10-dihydro-...

Embodiment 2~5

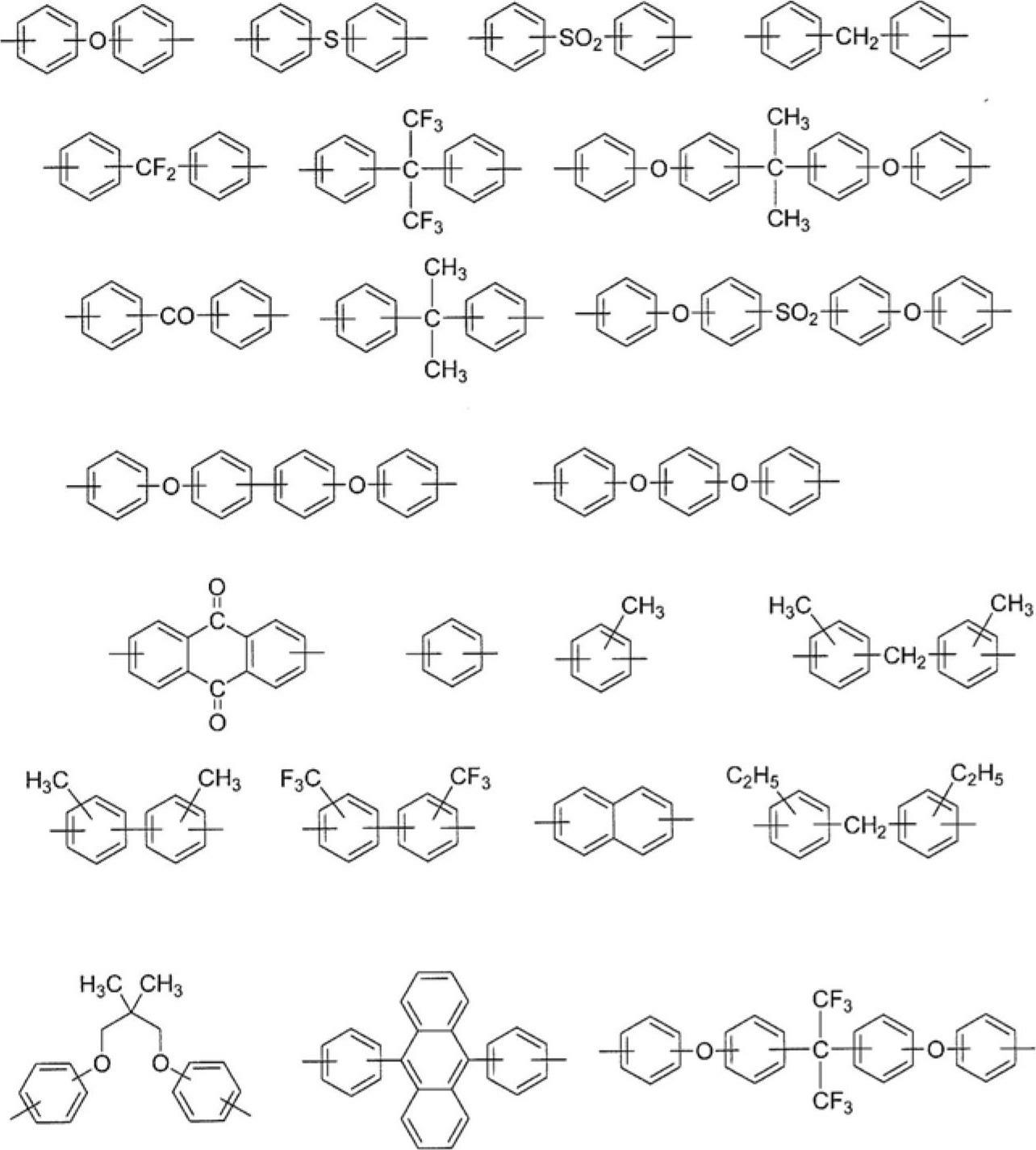

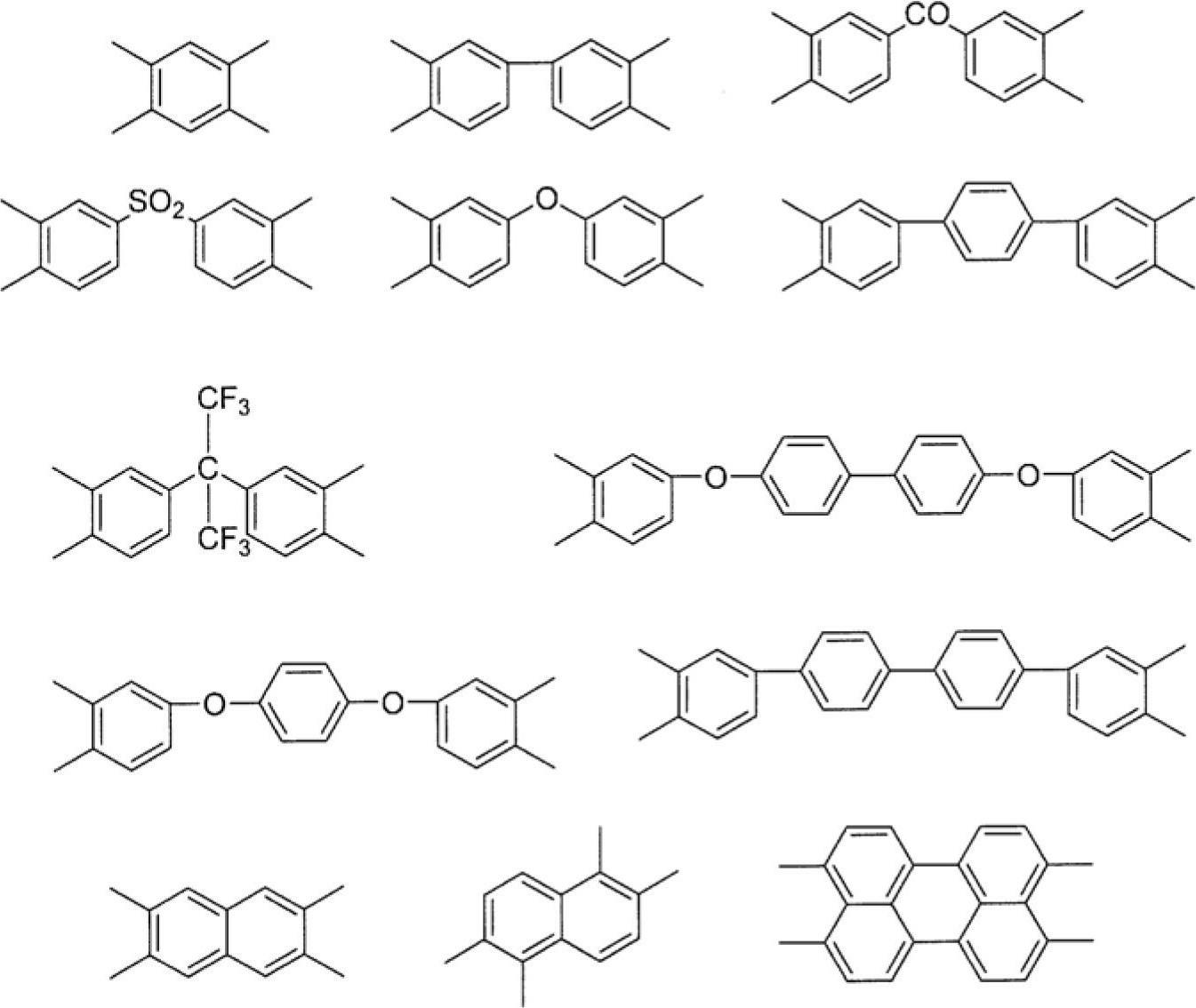

[0099] A negative electrode was obtained in the same manner as in Example 1 except that polyimide resins 2 to 5 having the compositions shown in Table 1 were used instead of the binder used in Example 1. About the obtained negative electrode, discharge capacity, output characteristic, and cycle characteristic were evaluated similarly to Example 1. The results are shown in Table 1. In addition, the meaning of the abbreviation written in Table 1 is as follows. For the polyimide resins 2 to 5, the precursors were respectively polymerized in the same manner as in Example 1, and imidized by heat treatment at the time of forming the active material layer.

[0100] BTDA: 3,3’,4,4’-Benzophenone tetracarboxylic dianhydride

[0101] BPDA: 3,3’,4,4’-Biphenyltetracarboxylic dianhydride

[0102] TPE-R: 1,3-bis(4-aminophenoxy)benzene

[0103] APB: 1,3-bis(3-aminophenoxy)benzene

[0104]

Embodiment 6

[0106] Lump coke (green coke) produced by using refined pitch obtained by removing quinoline-insoluble components from coal-based heavy oil and heat-treating at 500°C for 24 hours by the delayed coking method is micronized with a jet mill. Grinding and sizing were performed to obtain green coke powder with an average particle diameter of 9.9 μm.

[0107] The lump-shaped raw coke obtained as above was heat-treated at a temperature from 700° C. near the inlet to 1500° C. (the highest reaching temperature) near the outlet through a rotary kiln for more than 1 hour to obtain lump-shaped calcined coke. Finely pulverize and sizing, to obtain calcined coke powder with an average particle size of 9.5 μm.

[0108] To the total of 50 parts by mass of green coke powder and 50 parts by mass of calcined coke powder (100 parts by mass of coke powder) obtained as above, phosphoric acid ester (14 mass % active phosphorus solid resin: Sanko Corporation trade name HCA, chemical name : 9,10-dih...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com