Method for preparing crystal-phase-controllable monodispersed Cu2ZnSnS4 nanocrystalline

A nanocrystalline, monodisperse technology, applied in nanotechnology, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of solar cell cost reduction, difficulty in cleaning, high cost, etc., to reduce material cost, facilitate recycling, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

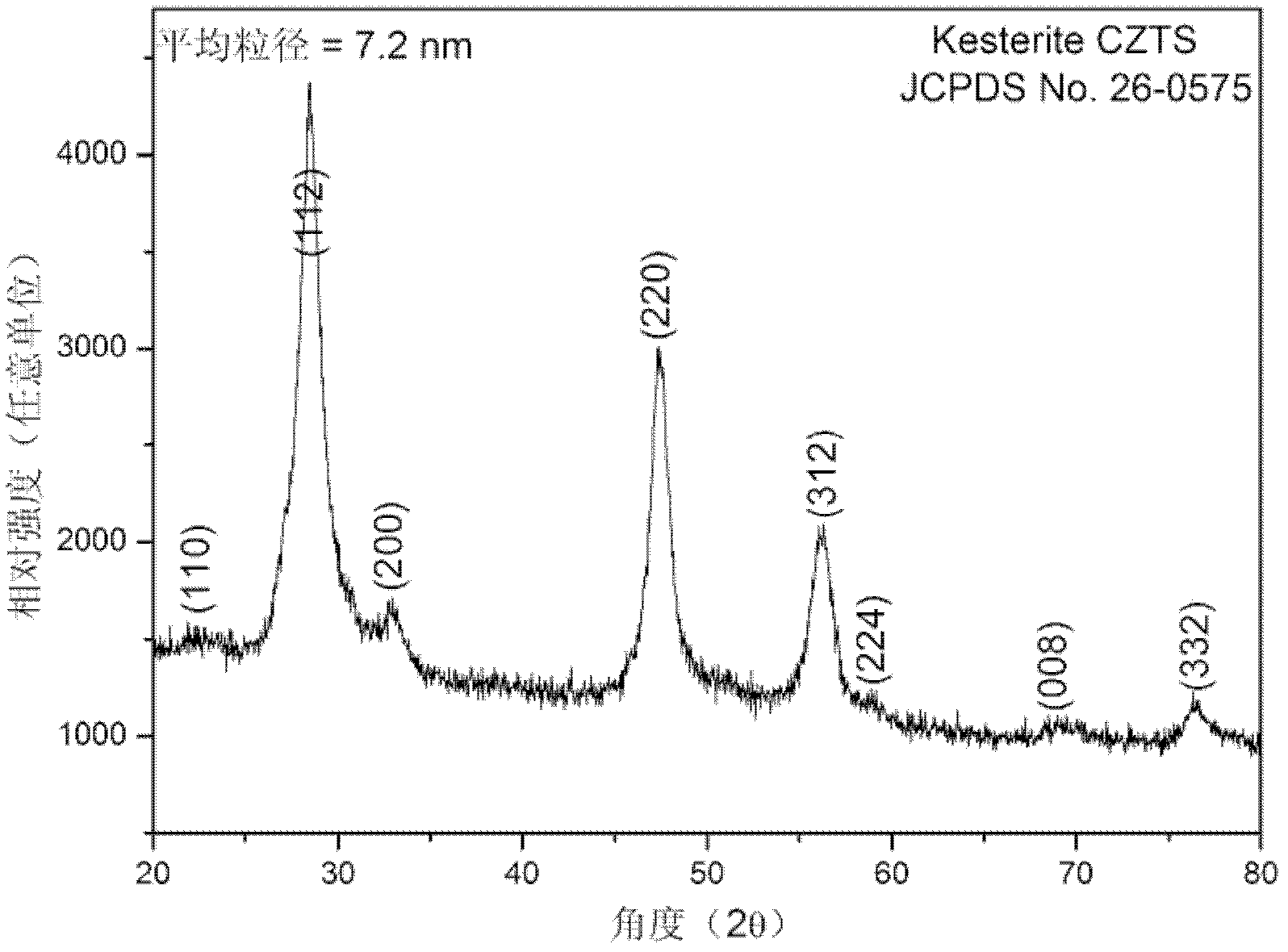

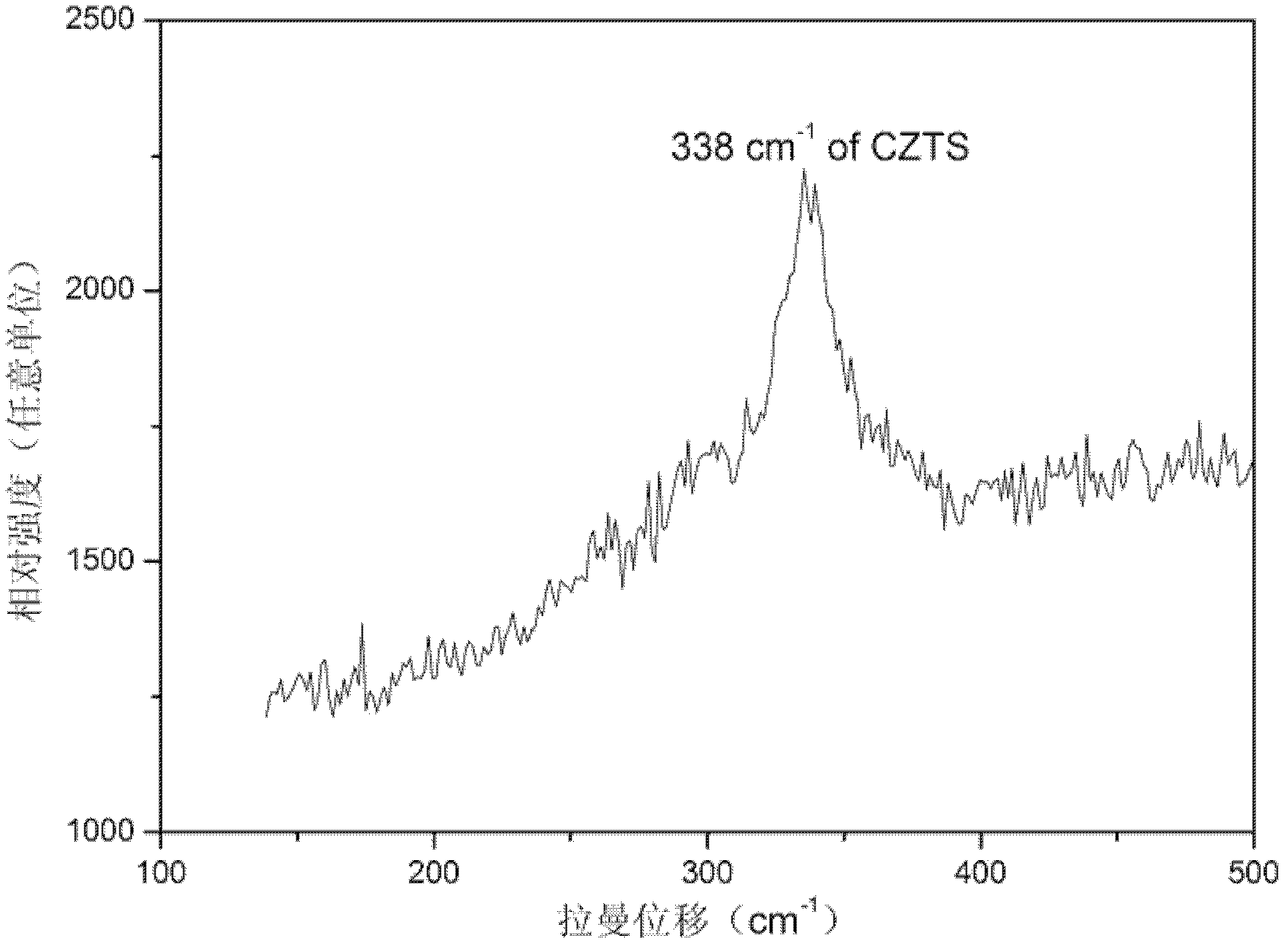

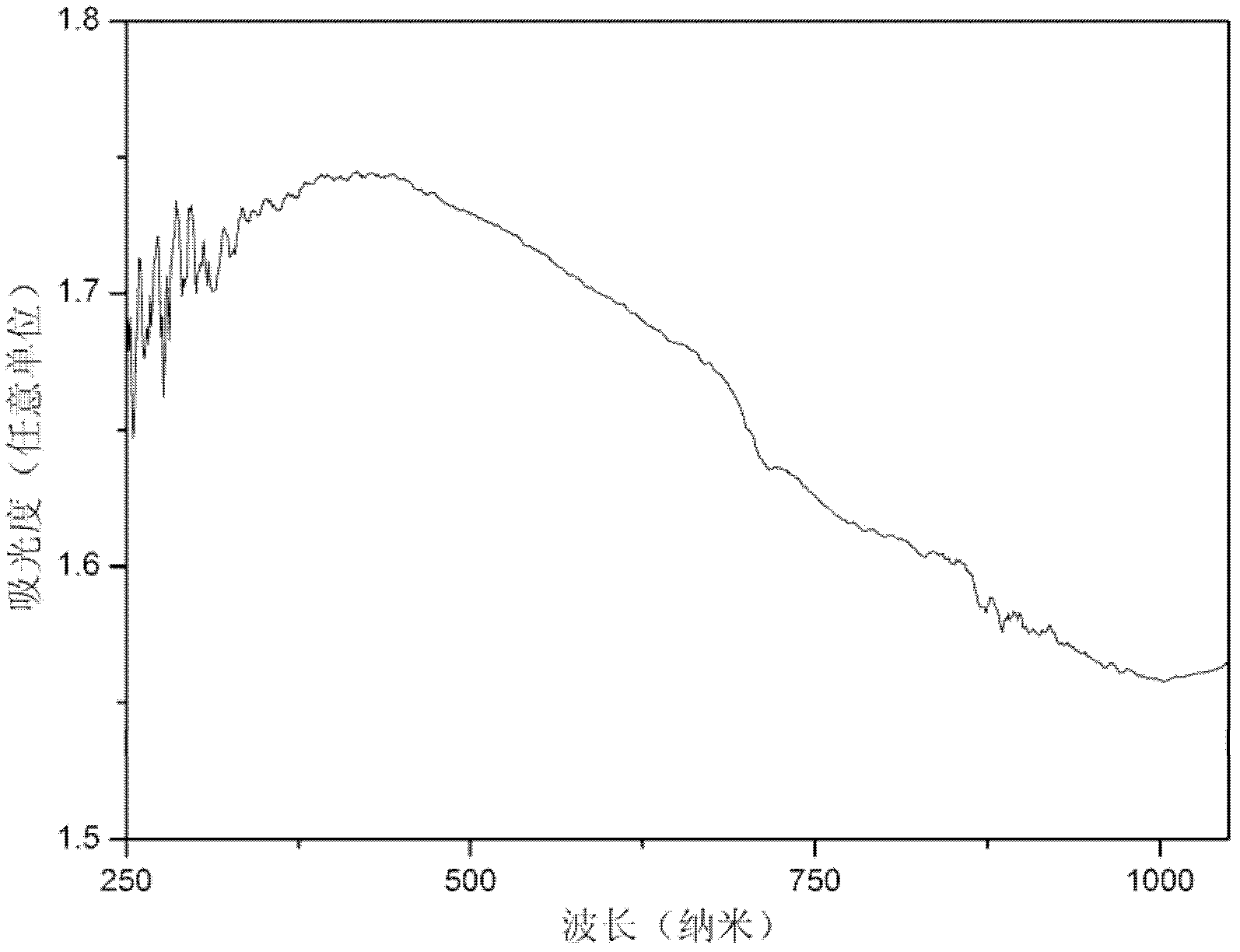

[0027] The embodiment of the present invention provides a crystal phase controllable monodisperse Cu 2 ZnSnS 4 The preparation method of nanocrystals (referred to as CZTS nanocrystals) is a cheap, simple, and scalable solvothermal growth method for preparing CZTS nanocrystals. It does not require expensive equipment and complicated processes. Metal chloride salts in alcohol solvents react with elemental sulfur at a certain temperature and under the protection of an inert gas. By adding a small amount of oleylamine to complex the precursors, react and disperse the products to inhibit their agglomeration and rapid growth, that is, to obtain crystal phases. Controlled monodisperse Cu 2 ZnSnS 4 nanocrystals, the method comprising:

[0028] Precursor complexation: metal chloride salts CuCl (copper chloride), ZnCl 2 (zinc chloride), SnCl 4 (Tin tetrachloride) and elemental sulfur (S) add in the container, add alcoholic solvent and oleylamine in the described container, feed nit...

Embodiment 1

[0046] This embodiment provides a crystal phase controllable monodisperse Cu 2 ZnSnS 4 The preparation method of nanocrystal (being called for short CZTS nanocrystal), the steps are as follows:

[0047] (1) Precursor complexation of CZTS nanocrystals: Weigh CuCl and ZnCl at a molar ratio of 2:1:4 2 , S powder, put into a three-necked flask as a reaction container, pour glycerin (or the mixed solution of glycerin and ethylene glycol, polyethylene glycol and other common solvents) and oleylamine as solvent (oleylamine account for 10% of the total solvent volume), the ratio of the total solvent volume to the moles of the final CZTS is 10mL: 1mmol, and feed N into the three-necked flask 2 The gas exhausts the air in it and has been in N 2 gas as a protective gas, heated to 80°C while stirring, press ZnCl 2 : SnCl 4 =1:1 molar ratio to take SnCl 4 The liquid is injected under the liquid surface of the reaction solution, and the temperature is raised to 120°C to 140°C for 1 ho...

Embodiment 2

[0052] This embodiment provides a crystal phase controllable monodisperse Cu 2 ZnSnS 4 The preparation method of nanocrystal (being called for short CZTS nanocrystal), the steps are as follows:

[0053] (1) Precursor complexation of CZTS nanocrystals: Weigh CuCl and ZnCl at a molar ratio of 2:1:4 2 , S powder, put into a three-necked flask as a reaction container, pour glycerin (or the mixed solution of glycerin and ethylene glycol, polyethylene glycol and other common solvents) and oleylamine as solvent (oleylamine account for 7% of the total solvent volume), the ratio of the total solvent volume to the moles of the final CZTS is 15mL: 1mmol, and feed N into the three-necked flask 2 The gas exhausts the air in it and has been in N 2 gas as a protective gas, heated to 80°C while stirring, press ZnCl 2 : SnCl 4 =1:1 molar ratio to take SnCl 4 The liquid is injected under the liquid surface of the reaction solution, and the temperature is raised to 120°C to 140°C for 1 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com