Method for preparing 3, 3- diphenyl propanol

A technology of diphenylpropanol and diphenylpropionic acid, applied in 3 fields, can solve the problems of not meeting green production requirements, difficult to control the reaction, many operation steps, etc., and achieve stable and reliable product quality, easy recovery and reuse, The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

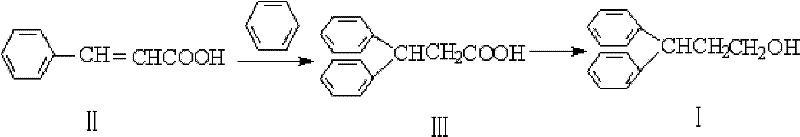

[0025] 1) Preparation of 3,3-diphenylpropionic acid (III):

[0026] Mix 31.2 g (0.4 mol) of benzene with 9.7 g of [bmim]Cl / AlCl 3 Mix the ionic liquids, raise the temperature to 70-80°C, add 7.4 grams (0.05 moles) of cinnamic acid in 4 batches within 0.5 hours; after the addition, heat up and reflux for 2 hours; after the reaction is complete, add 50 ml of water, stir well and let stand Layering, the water phase is a mixture of ionic liquid and water, which can be recycled after dehydration by vacuum distillation; the organic phase is recovered by vacuum distillation to recover unreacted benzene, and the obtained solid is a crude product, which is recrystallized with methanol and dried to obtain 3, 9.1 g (0.04 mol) of 3-diphenylpropionic acid, yield 80.4%.

[0027] 2) 3, the preparation of 3-diphenylpropanol (I):

[0028] Add 9.1 grams (0.04 moles) of 3,3-diphenylpropionic acid into 30 milliliters of anhydrous tetrahydrofuran, add 1.7 grams (0.044 moles) of sodium borohydrid...

Embodiment 2

[0030] 1) Preparation of 3,3-diphenylpropionic acid (III):

[0031] Mix 70.3 grams (0.9 moles) of benzene with 25.5 grams of [bmim]Cl / AlCl 3 Mix the ionic liquids, raise the temperature to 70-80°C, add 14.8 grams (0.1 moles) of cinnamic acid in 5 batches within 1.0 hour; after the addition, heat up and reflux for 4 hours; after the reaction is complete, add 100 ml of water, stir well and let stand Layering, the water phase is a mixture of ionic liquid and water, which can be recycled after dehydration by vacuum distillation; the organic phase is recovered by vacuum distillation to recover unreacted benzene, and the obtained solid is a crude product, which is recrystallized with methanol and dried to obtain 3, 18.5 g (0.082 mol) of 3-diphenylpropionic acid, the yield was 81.8%.

[0032] 2) 3, the preparation of 3-diphenylpropanol (I):

[0033] Add 18.5 grams (0.082 moles) of 3,3-diphenylpropionic acid into 60 milliliters of anhydrous ethylene glycol dimethyl ether, add 3.7 gr...

Embodiment 3

[0035] 1) Preparation of 3,3-diphenylpropionic acid (III):

[0036] Mix 156.2 grams (2.0 moles) of benzene with 65.0 grams of [bmim]Cl / AlCl 3 Mix the ionic liquids, heat up to 70-80°C, add 29.6 grams (0.2 moles) of cinnamic acid in 5 batches within 1.0 hour; after the addition, heat up and reflux for 3 hours; after the reaction is complete, add 200 ml of water, stir well and let stand Layering, the water phase is a mixture of ionic liquid and water, which can be recycled after dehydration by vacuum distillation; the organic phase is recovered by vacuum distillation to recover unreacted benzene, and the obtained solid is a crude product, which is recrystallized with methanol and dried to obtain 3, 37.2 g (0.164 mol) of 3-diphenylpropionic acid, yield 82.2%.

[0037] 2) 3, the preparation of 3-diphenylpropanol (I):

[0038]Add 37.2 grams (0.164 moles) of 3,3-diphenylpropionic acid into 120 milliliters of anhydrous ethylene glycol dimethyl ether, add 8.1 grams (0.213 moles) of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com