Polyurethane gel for marine exploration streamer and preparation method for same

A technology of polyurethane gel and polyurethane prepolymer, which is applied in the seismology of areas covered by water, etc., can solve the problems of complicated process and increased manufacturing cost of tow cables, achieve good processability and low density Requirements, Effects of Density Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

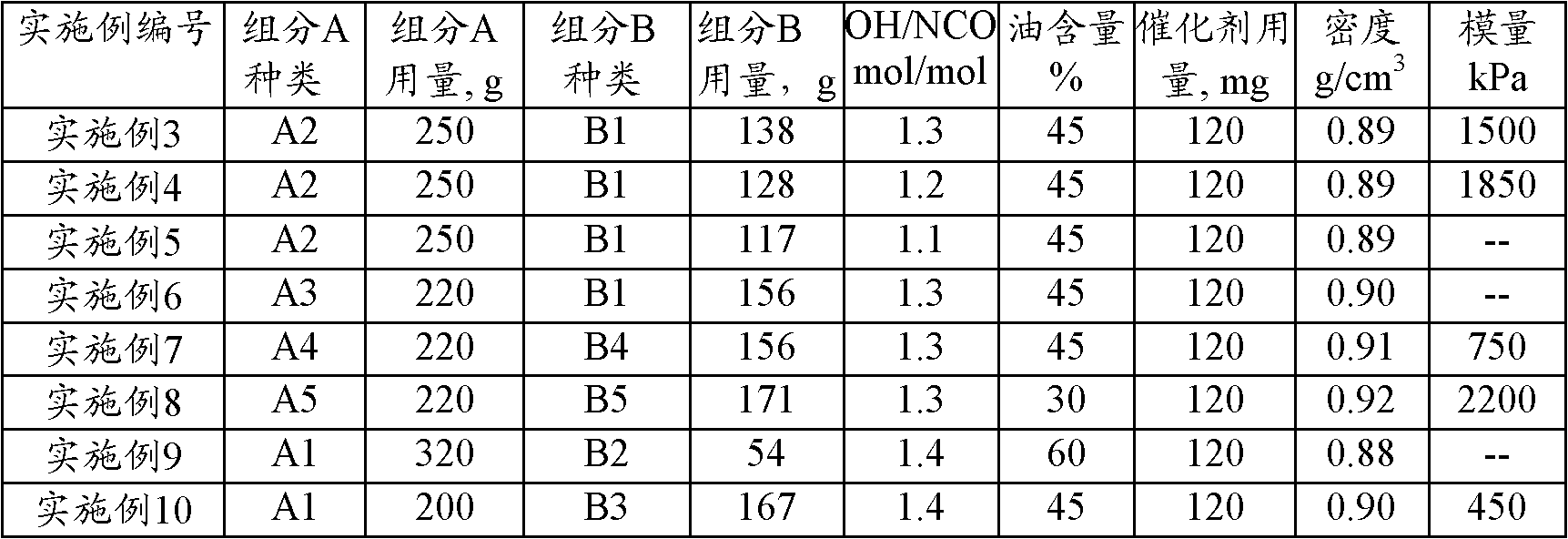

Examples

Embodiment 1

[0050] First, add 200g of PU1 into a 500mL reaction bottle, raise the temperature to 60°C, add 164g of D80, mix well, keep the vacuum at 0.09MPa, and degas for 1h. The hydroxyl-terminated polybutadiene polyurethane prepolymer solution, ie, component A, was obtained by discharging the material, with a solvent oil mass content of 45% and an isocyanate group NCO content of 1.38%.

[0051] Then, add 100g of N-210 into a 250mL reaction bottle, and dehydrate in vacuum at 120-140°C and 0.09MPa vacuum for 2h. Cool down to 40°C, remove the vacuum, add 81.8g of D80, mix evenly, and discharge to obtain a curing agent solution, that is, component B, whose solvent oil mass content is 45%, and the total hydroxyl value of the solution is 60.5KOH mg / g.

[0052] Then in the 500mL reactor, add the component A of 250g and the component B of 106g, mix homogeneously, after degassing 20min under vacuum (vacuum tightness 0.09MPa), add the catalyst stannous octoate of 110mg, mix homogeneously (oil ...

Embodiment 2

[0055] First, add 200g of PU2 into a 500mL reaction bottle, raise the temperature to 60°C, add 164g of D80, mix well, keep the vacuum at 0.09MPa, and degas for 1h. The hydroxyl-terminated polybutadiene polyurethane prepolymer solution, ie, component A, was obtained by discharging the material, with a solvent oil mass content of 45% and an isocyanate group NCO content of 1.93%.

[0056] Then, add 100 g of N210 into a 250 mL reaction bottle, and dehydrate in vacuum at 120-140° C. and 0.09 MPa vacuum for 2 hours. Cool down to 40°C, remove the vacuum, add 81.8g of D80, mix evenly, and discharge to obtain a curing agent solution, that is, component B, whose solvent oil mass content is 45%, and the total hydroxyl value of the solution is 60.5KOH mg / g.

[0057] Add 220g of Component A and 131g of Component B in a 500mL reactor, mix well, and after degassing under vacuum (vacuum degree 0.09MPa) for 20min, add 110mg of catalyst stannous octoate, mix well (the oil filling capacity is ...

Embodiment 11

[0067] First, add 200g of PU2 into a 500mL reaction bottle, raise the temperature to 60°C, add 164g of D70, mix well, keep the vacuum at 0.09MPa, and degas for 1h. The hydroxyl-terminated polybutadiene polyurethane prepolymer solution, ie, component A, was obtained by discharging the material, with a solvent oil mass content of 45% and an isocyanate group NCO content of 1.93%.

[0068] Next, add 100 g of N-210 into a 250 mL reaction bottle, and dehydrate in vacuum at 120-140° C. for 2 hours at a vacuum degree of 0.09 MPa. Cool down to 40°C, remove the vacuum, add 81.8g of D70, mix evenly, and discharge to obtain a curing agent solution, that is, component B. The mass content of solvent oil is 45%, and the total hydroxyl value of the solution is 60.5KOH mg / g.

[0069] Then, in the 500mL reactor, add the component A of 240g and the component B of 143g, mix homogeneously, after degassing 20min under vacuum (vacuum tightness 0.09MPa), add the catalyst stannous octoate of 120mg, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com