Foamed and molded cup and manufacturing method thereof

A technology of foam molding and cups, which is applied in brassieres, applications, clothing, etc., can solve the problems affecting the health of operators, the shape of cups is difficult to restore, and the volatilization speed of sweat stains is slow. Environmental protection and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

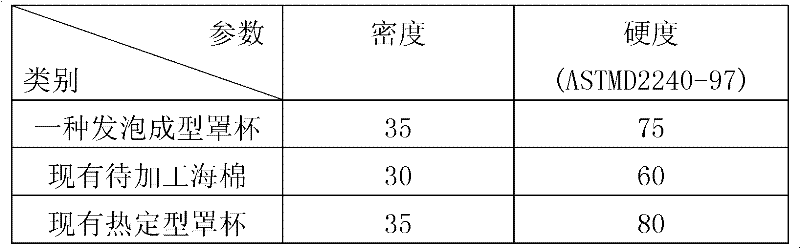

Embodiment 1

[0046] A foam molded cup, including main materials and auxiliary materials, the main materials and auxiliary materials are respectively according to the ratio of parts by weight:

[0047] Main ingredients: 60 parts of polyether propylene glycol (PPG); 25 parts of toluene diisocyanate (TDI);

[0048] Accessories: 2 parts of L-580 silicone foam stabilizer; 0.65 parts of stannous octoate T-9 tin catalyst; 0.5 parts of A-33 alkylamine; 0.1 parts of dichloromethane as foaming agent; 0.05 parts of water; 20 parts of CaCO 3 powder, the CaCO 3 The purity of the powder is 99%, the particle size is 200 mesh, and the humidity is 0.2%.

[0049] A method for manufacturing a foam-molded cup, comprising the steps of:

[0050] Step 1. Design the cup shape mold according to the required cotton cup shape, and use the CNC machining center to form the upper mold and the lower mold, which can be tightly fastened;

[0051] Step 2. Brush the mold of step 1 with release agent and heat it in an ov...

Embodiment 2

[0063] A foam molded cup, including main materials and auxiliary materials, the main materials and auxiliary materials are respectively according to the ratio of parts by weight:

[0064] Main ingredients: 70 parts of polyether propylene glycol; 27 parts of toluene diisocyanate;

[0065] Accessories: 2.5 parts of L-580 silicone foam stabilizer; 0.7 parts of stannous octoate T-9 tin catalyst; 0.7 parts of A-33 alkylamine; 0.15 parts of dichloromethane; 0.12 parts of water; 15 parts CaCO 3 powder, the CaCO 3 The purity of the powder is 99%, the particle size is 200 mesh, and the humidity is 0.2%.

[0066] A method for manufacturing a foam-molded cup, comprising the steps of:

[0067] Step 1. Design the cup shape mold according to the required cotton cup shape, and use the CNC machining center to form the upper mold and the lower mold, which can be tightly fastened;

[0068] Step 2. Brush the mold of step 1 with release agent and heat it in an oven for 4 hours. The temperatur...

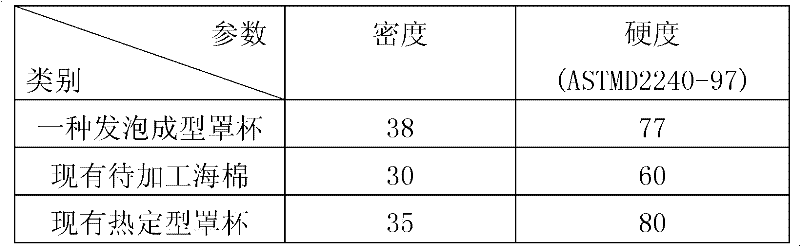

Embodiment 3

[0080] A foam molded cup, including main materials and auxiliary materials, the main materials and auxiliary materials are respectively according to the ratio of parts by weight:

[0081] Main ingredients: 65 parts of polyether propylene glycol; 26 parts of toluene diisocyanate;

[0082] Excipients: 2.19 parts of L-580 silicone foam stabilizer; 0.68 parts of stannous octoate T-9 tin catalyst; 0.6 parts of A-33 alkylamine; 0.13 parts of dichloromethane; 0.08 parts of water; 17 parts CaCO 3 powder, the CaCO 3 The purity of the powder is 99%, the particle size is 200 mesh, and the humidity is 0.2%;

[0083] A method for manufacturing a foam-molded cup, comprising the steps of:

[0084] Step 1. Design the cup shape mold according to the required cotton cup shape, and use the CNC machining center to form the upper mold and the lower mold, which can be tightly fastened;

[0085] Step 2. Brush the mold of step 1 with release agent and heat it in an oven for 3 hours, the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com