Biomass composite fuel production system

A production system and composite fuel technology, applied in waste fuel, fuel, solid fuel and other directions, can solve the problems of insufficient understanding of the necessity of sludge treatment and disposal, insufficient sludge treatment and disposal, low sludge treatment rate, etc. The installation structure is compact, the stirring time is shortened, and the environmental requirements are not high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

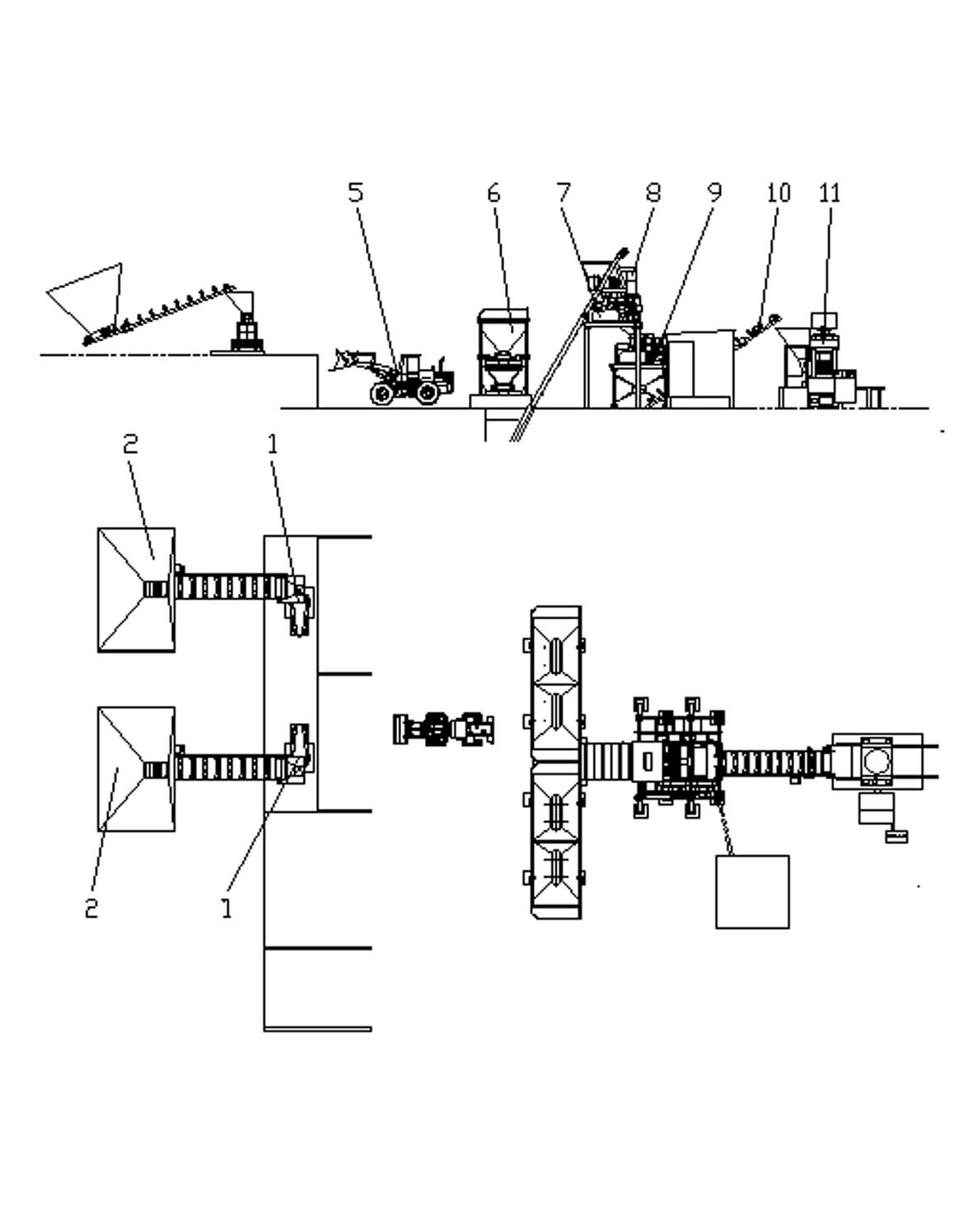

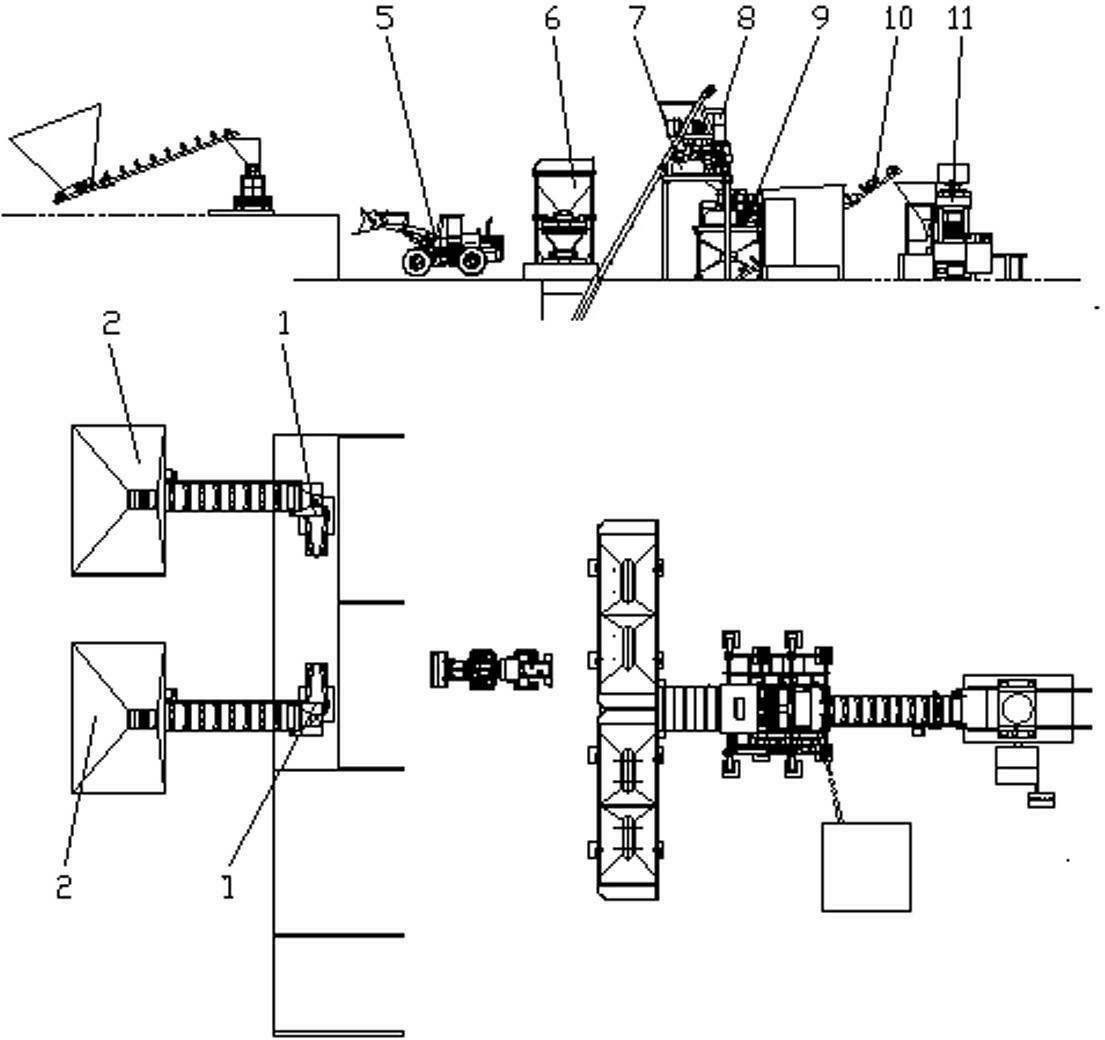

[0015] see figure 1 , a biomass composite fuel production system, including a raw coal pulverizer 1 for pulverizing raw coal and a straw pulverizer 2 for pulverizing biological raw materials, and pulverizing raw coal and biological raw materials (straw materials) through raw coal Machine 1 and stalk pulverizer 2 carry out physical processing, and the raw coal after pulverizing, stalk, sludge, quicklime are shoveled into four storage bins of batching machine 6 with loader 5 respectively, and batching machine 6 presses the above-mentioned The material is automatically distributed to the weighing hopper, and the weighed mixture is added to the upper hopper of the forced mixer 7 at regular intervals, and then the lifting device of the mixer 7 transports the material to the mixing tank according to the instruction, and the dosage scale 8 is automatically ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com