Preparation method of starch ester adsorbing material

An adsorption material, starch ester technology, applied in the field of preparation of chemically modified derivatives, to achieve the effect of increasing adsorption effect, improving processing performance, and good biodegradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

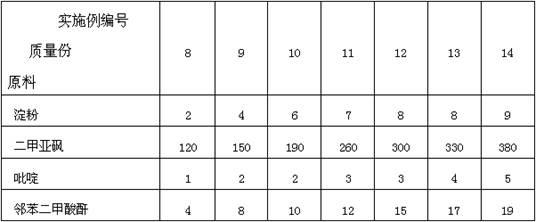

Examples

Embodiment 1

[0022] A method for preparing a starch ester adsorption material, comprising: taking 5 parts by mass of starch, adding 200 parts by mass of organic solvent dimethyl sulfoxide, and stirring at 80° C. for 1 hour until fully dissolved. Then, 1 mass part of pyridine catalyst and 5 mass parts of phthalic anhydride were added, and the mixture was stirred and reacted at 60° C. for 6 hours to obtain a reaction mixture. After the reaction mixture was cooled to room temperature, a sufficient amount of ethanol was added to precipitate, filtered, and the precipitate was repeatedly washed with 95% ethanol, and the product was dried in a blast drying oven at 50°C for 24 hours to obtain the final product starch ester adsorption material.

Embodiment 2

[0024] A method for preparing a starch ester adsorption material, comprising: taking 5 parts by mass of starch, adding 200 parts by mass of organic solvent dimethyl sulfoxide, and stirring at 80° C. for 1 hour until fully dissolved. Then 2 parts by mass of pyridine catalyst and 10 parts by mass of phthalic anhydride were added, and the mixture was stirred and reacted at 60° C. for 6 hours to obtain a reaction mixture. After the reaction mixture was cooled to room temperature, a sufficient amount of ethanol was added to precipitate, filtered, and the precipitate was repeatedly washed with 95% ethanol, and the product was dried in a blast drying oven at 50°C for 24 hours to obtain the final product starch ester adsorption material.

Embodiment 3

[0026] A method for preparing a starch ester adsorption material, comprising: taking 5 parts by mass of starch, adding 200 parts by mass of organic solvent N,N-dimethylformamide, and stirring at 80° C. for 1 hour. Then, 1 mass part of pyridine catalyst and 10 mass parts of phthalic anhydride were added, and the mixture was stirred and reacted at 60°C for 6 hours to obtain a reaction mixture. After the reaction mixture was cooled to room temperature, a sufficient amount of ethanol was added to precipitate, filtered, and the precipitate was repeatedly washed with 95% ethanol, and the product was dried in a blast drying oven at 50°C for 24 hours to obtain the final product starch ester adsorption material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com