Dry-mixed mortar

A technology of dry-mixed mortar and machine-made sand, which is applied in the field of mortar, and can solve the problems of dry-mixed mortar whose workability and strength are not up to the standard, the content of stone powder varies greatly, and there are too many needles, so as to achieve good gradation and stone powder The effect of small content change and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

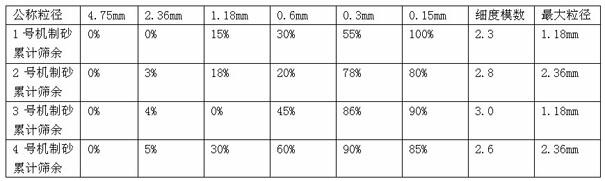

[0035] To prepare pebble machine-made sand dry-mixed mortar, measure and weigh the raw materials according to the following proportions

[0036] Cement: 120 parts

[0037] No. 1 pebble machine-made sand: 700 parts

[0038] Fly ash: 80 parts

[0039] Water reducing agent: 2.5 parts

[0040] Air-entraining agent: 1.5 parts

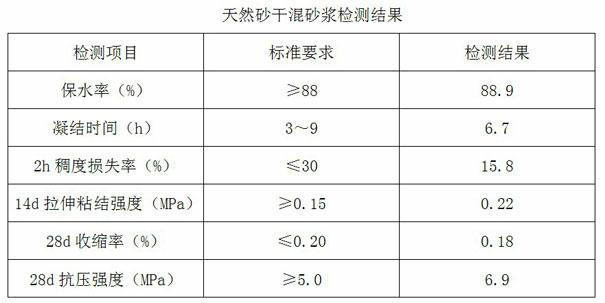

[0041] The various raw materials are weighed by the weighing scale and mixed evenly in the mixing and stirring equipment to obtain the required finished dry-mixed mortar. The standard test is carried out, and the test results are as follows:

[0042]

Embodiment 2

[0044] To prepare pebble machine-made sand dry-mixed mortar, measure and weigh the raw materials according to the following proportions

[0045] Cement: 120 parts

[0046] No. 2 pebble machine-made sand: 750 parts

[0047] Fly ash: 80 parts

[0048] Water reducing agent: 1.8 parts

[0049] Air-entraining agent: 1.0 parts

[0050] Thickener: 1.2 parts

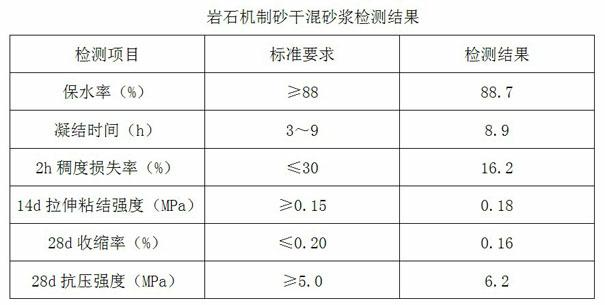

[0051] The various raw materials are weighed by the weighing scale and mixed evenly in the mixing and stirring equipment to obtain the required finished dry-mixed mortar. The standard test is carried out, and the test results are as follows:

[0052]

Embodiment 3

[0054] To prepare pebble machine-made sand dry-mixed mortar, measure and weigh the raw materials according to the following proportions

[0055] Cement: 120 parts

[0056] No. 3 pebble machine-made sand: 800 parts

[0057] Fly ash: 80 parts

[0058] Thickener: 2.2 parts

[0059] Air-entraining agent: 1.8 parts

[0060] The various raw materials are weighed by the weighing scale and mixed evenly in the mixing and stirring equipment to obtain the required finished dry-mixed mortar. The standard test is carried out, and the test results are as follows:

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com