Adsorbing agent for capturing CO2 in flue gas, and preparation method thereof

An adsorbent and flue gas technology, applied in the field of flue gas purification, can solve the problems of high separation cost, small molecular weight, low load capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

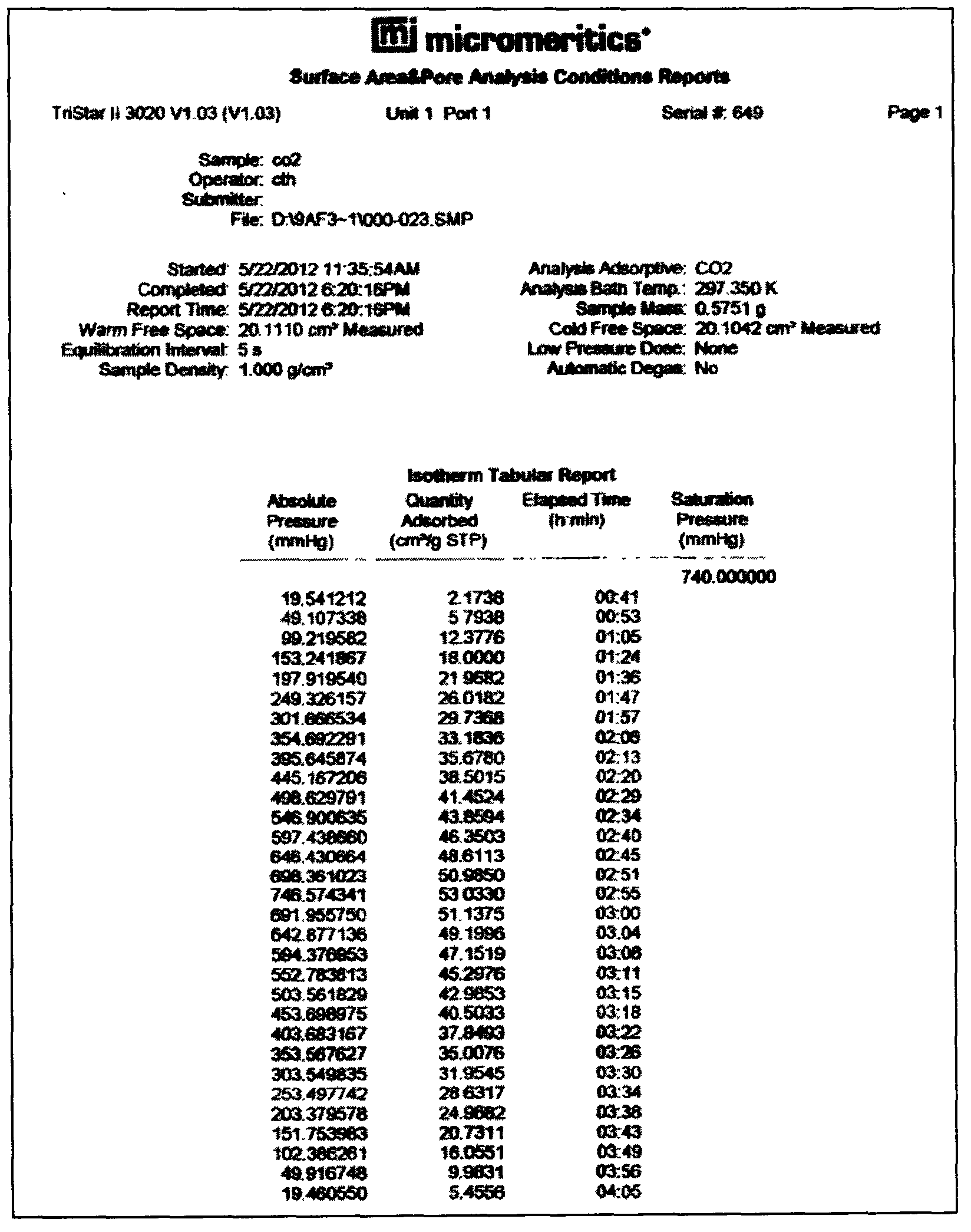

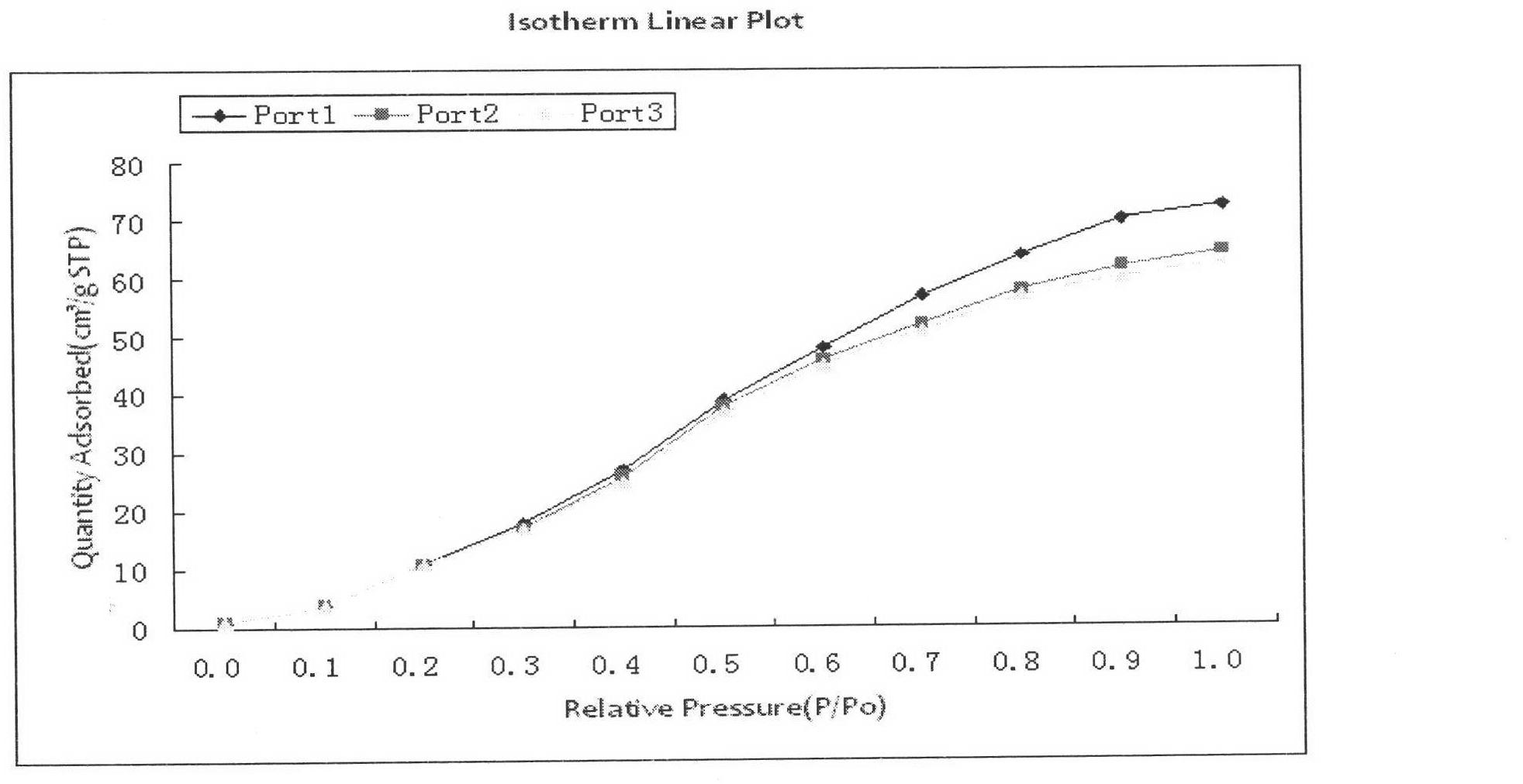

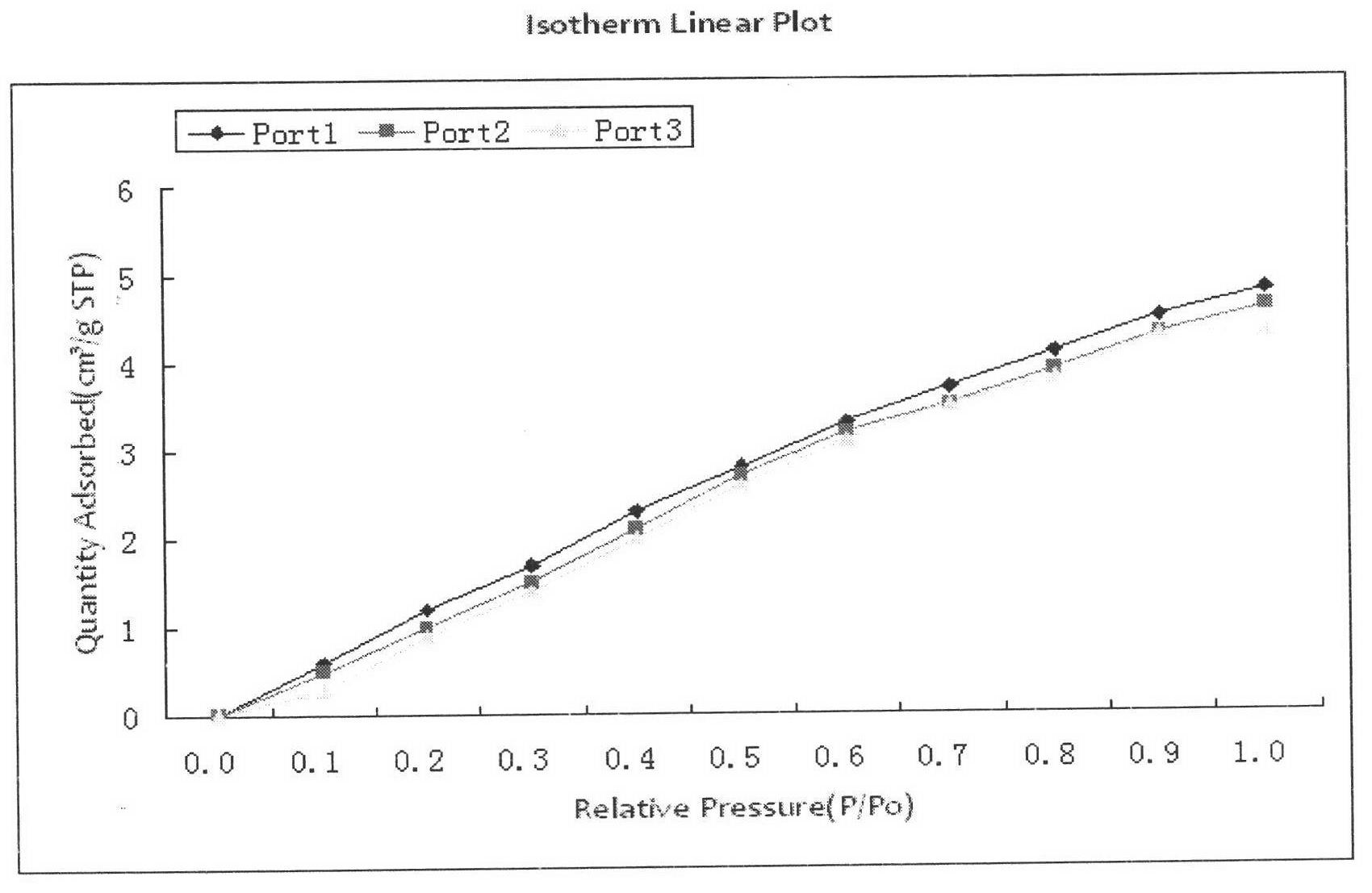

Image

Examples

Embodiment 1

[0021] Weigh 8.0g of activated carbon AC302, place it in a drying dish, use a 1000ml graduated cylinder to measure 600ml of deionized water and pour it into a 2000ml beaker, then put the beaker into a water bath, and control the temperature of the water bath to 75°C. After 45 minutes, Test the temperature of the deionized water in the beaker. When the temperature of the deionized water reaches above 65°C, add 300ml of monoethanolamine taken from the graduated cylinder, wash the residual monoethanolamine in the graduated cylinder with a little deionized water, and pour it into the beaker; weigh K 2 CO 3 : 35.2g, CNTs: 3.8g, add them together into the beaker, control the liquid temperature in the beaker to 65-75°C; gently stir the carrier at the bottom of the beaker with a glass rod every 15-20 minutes; separate the beaker after 1.5 hours Carrier and solution in the solution, put the separated carrier into the reaction tube with electric heater temperature control, the temperatu...

Embodiment 2

[0024] Weigh 8.7g of activated carbon AC302, place it in a drying dish, use a 1000ml graduated cylinder to measure 800ml of deionized water and pour it into a 2000ml beaker, then put the beaker into a water bath, and control the temperature of the water bath to 70°C. After 45 minutes, Test the temperature of the deionized water in the beaker. When the temperature of the deionized water reaches above 65°C, add 200ml of monoethanolamine taken from the graduated cylinder, wash the remaining monoethanolamine in the graduated cylinder with a little deionized water, and pour it into the beaker; weigh K 2 CO 3 : 46.4g, CNTs: 5.6g, add them together into the beaker, control the liquid temperature in the beaker to 65-70°C; gently stir the carrier at the bottom of the beaker with a glass rod every 15-20 minutes; separate the beaker after 1.5 hours Carrier and solution in the solution, put the separated carrier into a reaction tube with electric heater temperature control, the temperatur...

Embodiment 3

[0027] Weigh 9.9g of activated carbon AC302, place it in a drying dish, use a 1000ml graduated cylinder to measure 800ml of deionized water and pour it into a 2000ml beaker, then put the beaker into a water bath, and control the temperature of the water bath to 67°C. After 45 minutes, Test the temperature of the deionized water in the beaker. When the temperature of the deionized water reaches above 65°C, add 220ml of monoethanolamine taken from the measuring cylinder, wash the residual monoethanolamine in the measuring cylinder with a little deionized water, and pour it into the beaker; weigh K 2 CO 3 : 39.2g, CNTs: 7.6g, add them together into the beaker, control the liquid temperature in the beaker to 65-67°C; gently stir the carrier at the bottom of the beaker with a glass rod every 15-20 minutes; separate the beaker after 1.5 hours Carrier and solution in the solution, put the separated carrier into a reaction tube with electric heater temperature control, the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com